SOLOMON LUNGER

.

March 15, 2023

.

Department

SOLOMON LUNGER

.

March 15, 2023

.

Department

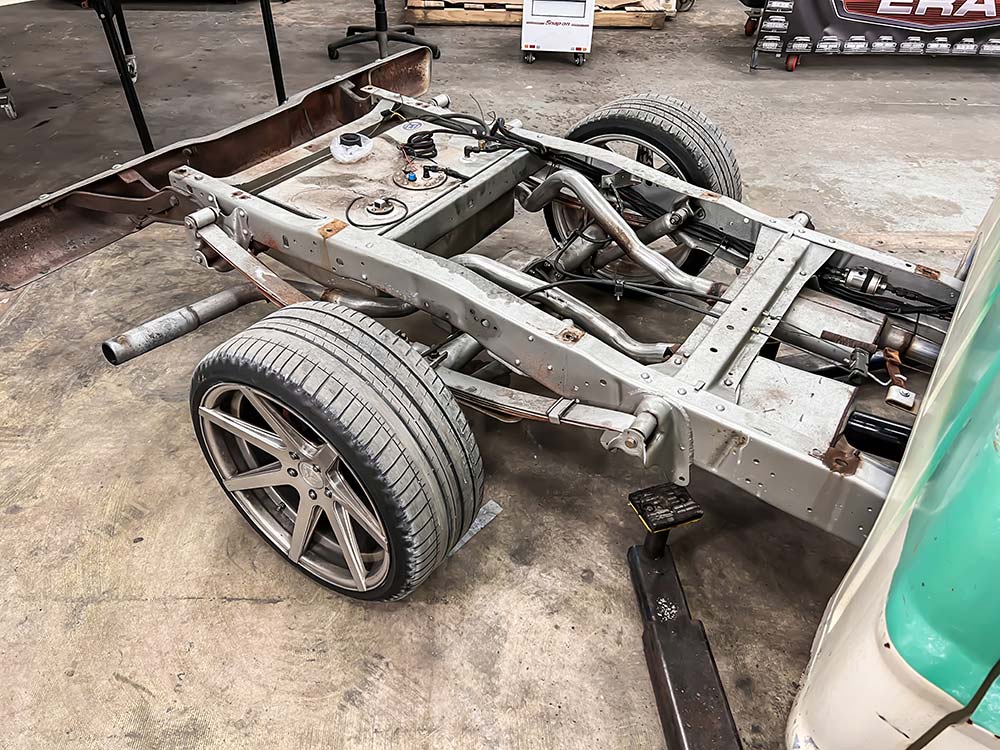

In the last issue of FBG, we did some Crown Vic front upgrades to our 1967 F-100, and we wanted to keep the rhythm going and address the rear suspension too.

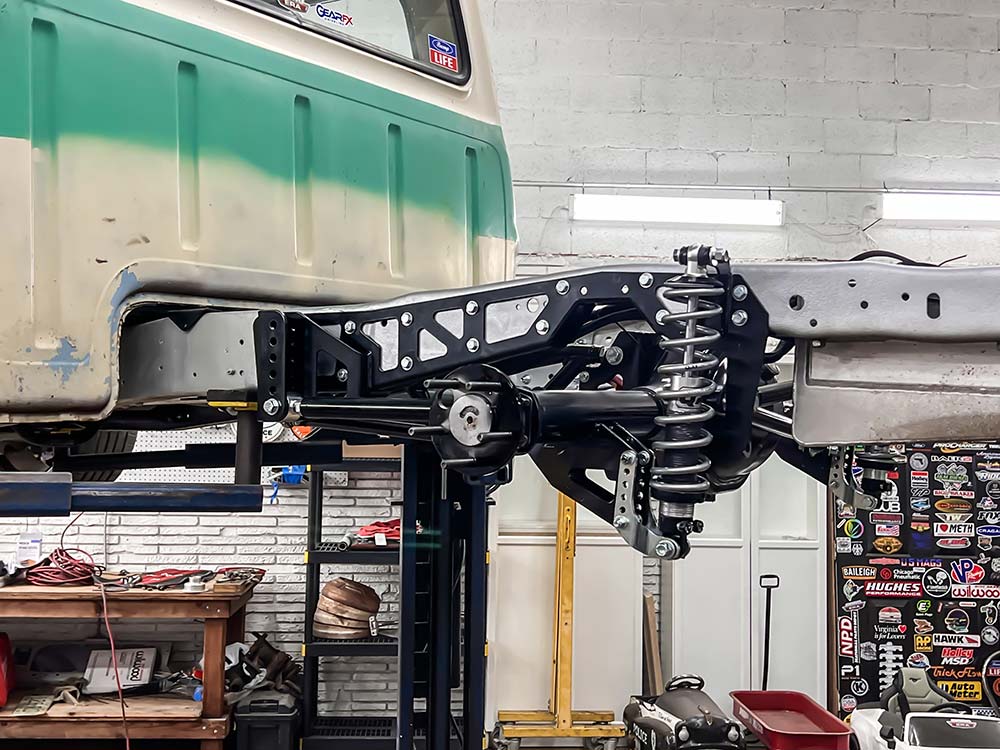

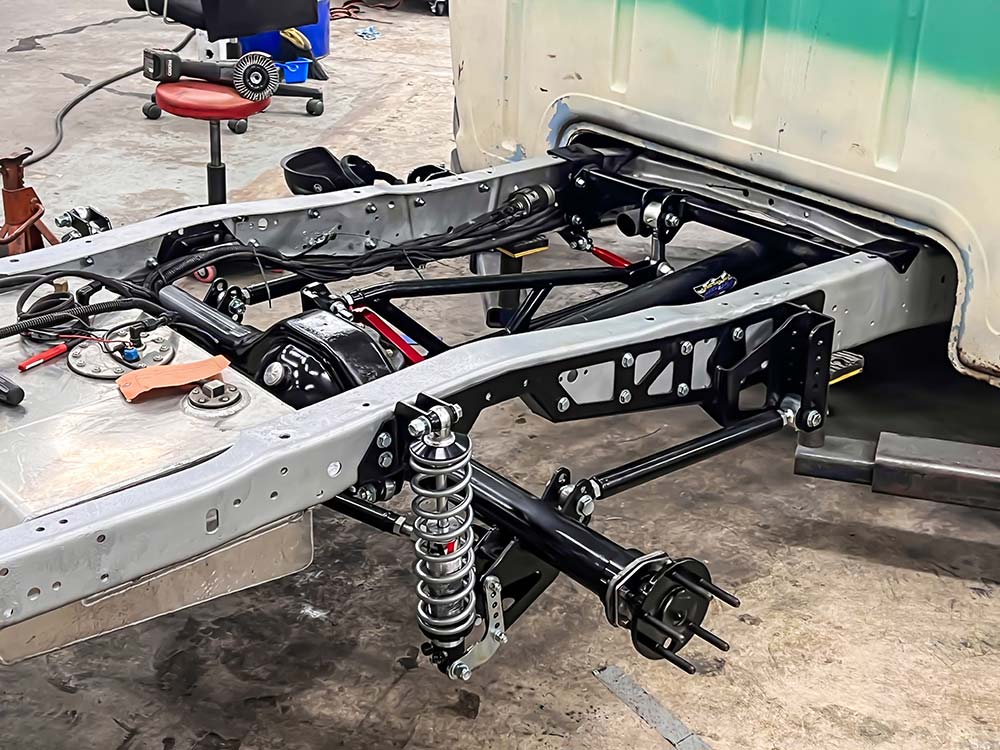

We have some fun plans with this ’67 F-100, and power is one of them. With that in mind, we elected to go for a new 9-inch GearFX driveline housing with 35 spline axles, 3:70 gears, a Detroit locker. To hold that monster of a rearend in place, we have the QA1 rear suspension. Just like up front, we went with a matching set of Baer Brakes Pro+ 6-piston setup.

One thing we did a little differently than a usual QA1 install is that we welded the QA1 axle parts to the axle instead of bolting it on, just because of what the intent of the final build is.

Share Link