Chris Hamilton

.

January 13, 2025

.

c10

Chris Hamilton

.

January 13, 2025

.

c10

Making The Most Of A Hand-Me-Down C10

With the hunt for good project trucks getting tighter these days, it must be nice to finally catch a break. There are still deals to be had out there, but definitely not like before. Expecting a little less while paying a little more seems to be the way things are headed when looking for an old truck to rip into, but every now and then, the universe has a way of rewarding a few lucky guys who deserve a bit of good fortune.

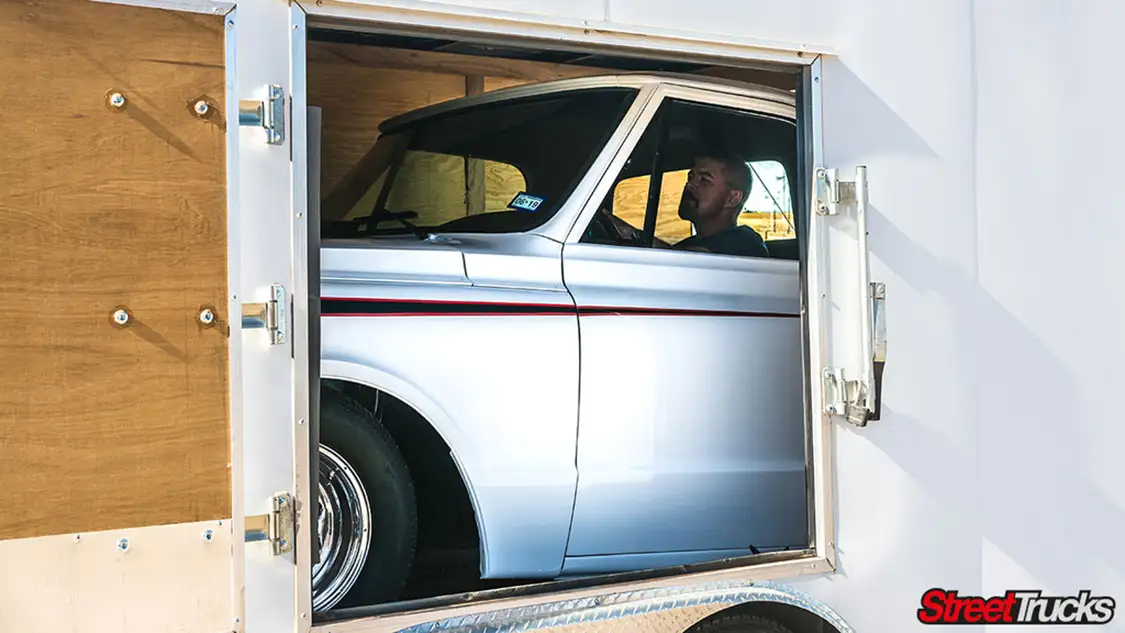

Robert Crowley can definitely place himself in the category of guys who lucked out in a major way. The ’68 C10 he has now was handed down to him 18 years ago before the whole Chevy frenzy began. If he had the extra cash lying around back then, he probably would’ve ended buying something to work on, but his options were few being a young guy on a razor-thin budget. “I acquired the truck back in ‘99”, Robert reminisces. “My wife’s uncle had bought it for his son to work on as a project. It was a rusted, straight-6, 3 on the tree step side. The project never got off the ground, and her uncle was looking to get rid of it—man I wanted it bad.”

Knowing that his wife would never say yes to a money pit of a truck so soon after they got married, all Kevin could do was dream about being able to buy it. The young couple was just starting out and didn’t really have a whole lot of money to be throwing around on a vehicle that wasn’t even drivable. “Her uncle understood the position we were in, and he knew how much I wanted the truck. He also just wanted to get rid of it, so he gave it to us on the agreement that I would keep it, fix it up and drive it one day. How could the wife say no to that?”

Within the first year of owning the truck, Robert swapped the bed, threw on a 5/7 static lowering kit, and body dropped it. He also yanked the original engine to help fund a swap later down the line. Not a bad start, that’s for sure. Bit by bit, he continued to strip it down to bare bones to get a better idea of what the next steps were going to be. Things were looking good for the truck, but it was sidelined for a few years once the Crowleys welcomed two new additions to their family. “After my son and daughter were born, I didn’t have much time to spend in the garage. But I did continue to purchase sheetmetal and engine parts that I stashed aside for when the time was right again.”

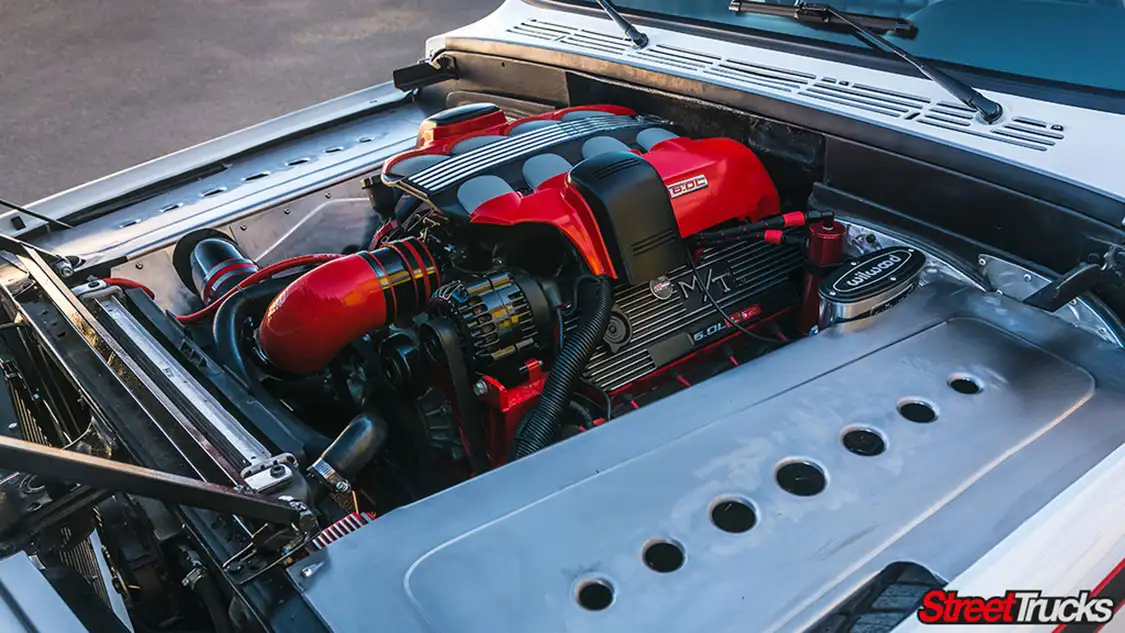

5 years went by since Robert’s last time spent with his truck, but 2007 brought a new beginning. “During that time we had purchased a new house and I was able to build a 24×24 garage just for my ‘baby’. My kids were finally old enough to allow me more time to fiddle around now, and I was more than ready to get back to work.” Robert had been buying parts to piece together a 496 stroker, but the whole LS trend was just gaining steam, so he opted to sell off his old go-fast parts to build another engine for his C10. The original plan had mildly changed course during the period of downtime, but Robert regained momentum and carried on.

Robert planned on doing as much work to the truck as he could himself, mainly for two major reasons. The first reason, well, he really didn’t have the money to blow on parts AND paying someone else’s labor rates. Secondly, Robert has always been the type of guy who tries to learn along the way and show pride in his rides. Since he was a senior in high school (’95), he has owned and worked on his own custom vehicles, and figured he could carry his experience and work ethic into his most ambitious project to date. “I’ve been around hot rods all my life but I also come from a poor family, so I learned at a young age that if you want something bad enough, you have to work hard get it. I am just fortunate that the good Lord blessed me with the talents to be able to put my mind to stuff like this and actually pull it off.”

With that outlook, Robert jumped headfirst into the build with no previous welding or bodywork skills to speak of. Now that his 18-year C10 build can be considered complete, he can safely say that he is confident in both trades. “The way I look at it is, if I see it I can build it. I spend a lot of time researching other people’s builds and techniques, and I can take a skill like welding and apply it to the task at hand. All I can really offer as advice to others looking to do work they aren’t familiar with is to take their time, be patient and remember that everything is fixable—for the most part.”

Robert completed his LS swap by whipping up his own motor mounts and crossmember, rewired the stock harness, and with the assistance of healthy amount of performance products, tuned the engine for optimum output. The interior work, including the custom center console, upholstery work and custom double hump dash transplant is the result of Robert’s own hard work and dedication to building the truck on his own. He was able to get the body straight enough to paint, but called on friend Sandy Garcia to wield the gun and finish the job. You gotta know when to hold ‘em and when to fold ‘em, and he trusted his better judgment to leave the paintjob to a professional.

Doing things this way is definitely not easy or time consuming—Robert will definitely be the first to tell you that. The entire process ran the course of nearly two decades to complete, but in the end, the build remained within goal and within a very doable budget for just about any income bracket to afford. “You don’t have to be rich to make a statement. I wanted to stick to a nostalgic muscle truck vibe combined with modern flare. The one important factor that I felt was important was to keep the truck feeling like it was still mostly stock—like it was a special edition offered straight from the factory.”

While there are still a few more items to attend to, Robert has been able take his pride and joy out to local car shows while sharing the completion of his years-long passion project. His story is quite inspirational, given that not all of us out there can afford to own magazine worthy trucks without getting our own hands dirty. “Even though it seemed that the truck would never be done, the end result always pays off if you follow through with the vision in your head.”

Truck Specs

Owner

Robert Crowley

1968 Chevy C10

Brownfield, TX

Engine

• ‘02 Chevy 6.0L V-8

• ‘02 4L80E transmission

• Custom motor mounts

• Custom transmission x-member

• Rewired stock harness

• Custom tune by Jesse Bubb @ Wait4Me Performance

• Sinister camshaft

• .591/.601 lift

• 230/236 110 LSA duration

• PRC Beehive springs

• Brian Tooley pushrods

• Custom 3-inch exhaust system

• Stock coils, MSD wires

• Racetronix fuel pump with Hotwire kit

• Freak Show Performance stall converter

• Derale 259-15900 transmission cooler

• Quick Performance narrowed 9-inch rearend

• Moser Wavetrac limited slip

• ’71 front disc brakes, Cadillac metric rear discs

• Wilwood tandem master cylinder, proportioning valve and 7:1 pedal

• Custom floor mount parking brake

Chassis & Suspension

• Factory ’69 frame

• Porterbuilt 1-inch narrow

• 1-inch forward tubular arms

• Western Chassis 2 ½-inch drop spindles

• CPP trailing arm x-member, Deluxe trac bar

• 3-inch Z at core support

• Air Lift 2600 ‘bags at all 4 corners

• Doshtech shocks

• Custom skid plates

• RedHead steering box

• ’02 Camaro fuel tank mounted behind axle

Wheels & Tires

• 15×8 and 15×12 Weld Draglite wheels

• 255/60/15 Cooper Cobra and 345/55/15 BFG Drag radial tires

Body & Paint

• Shop: Paint by Sandy Garcia

• Matrix GM Olympic white, graphics Matrix black and Victory red

• Handmade grille

• Mod Shop Metalwerks bumpers

• Tubbed rear wheel wells

• Fesler Built rear taillights

• Custom LED accessory lights

• Custom front end (’69 Camaro) tilt hood, ’67 conversion

• Eddie Motorsports door handles

• 3-inch bodydrop

Interior & Stereo

• Corbeau Baja low back seats wrapped in black vinyl

• Intellitronix 6-gauge custom instrumentation

• Forever Sharp Black Muscle mahogany steering wheel

• RodDoors panels

• Sony head unit

• JBL 6×9 and 6 ½ speakers

• Custom console wrapped in carbon fiber

• Smoothed ’61 dash swap

Share Link