Marcel Venable And Jason Mulligan

.

May 28, 2025

.

Tech

.

COURTESY OF PPC CUSTOMS

Marcel Venable And Jason Mulligan

.

May 28, 2025

.

Tech

.

COURTESY OF PPC CUSTOMS

One of life’s greatest challenges is fear, and the best way to overcome it is to arm yourself with knowledge. Fear can take any shape depending on the individual, but the most common form I’ve encountered (and even suffered from myself) is of computers and technology when it comes to building custom trucks.

I’m not really sure what it is about computers. Most of the guys I talk to think of electronics as a different language, and they don’t have any desire to learn it. Whether you’re an old school motor guru who times his engine by ear, or a newbie who doesn’t have a clue about what they’re doing, getting the most from your engine can be an overwhelming task. But if our common enemy is the computer, we’re all missing out on a powerful tool that can benefit engine performance.

Let’s take, for example, how truck manufacturers and professional engine builders view computers. To these folks computers are just another tool in the toolbox. A good example of how engineers use computers to improve truck performance is the advancement of electronic fuel injection or EFI. I know EFI has been around for many decades and it’s used on everything from factory power plants to high horsepower engines, but what is the main reason why EFI gives us such an advantage over its tried and true counterpart the carburetor? Efficiency and adjustability, my friend!

Electronic fuel injection allows the individual to control many more variables than a carburetor will ever permit. Anybody who has ever had a carbureted engine knows that cold starts, flooding, stalls, hesitation and poor fuel mileage can all be traced to a poorly tuned carb, which is essentially outdated fuel delivery technology.

So what’s the big deal, why is EFI so scary? Most truck owners know about computers, and that EFI is a good way of producing more power and efficiency, but most don’t know anything more than EFI involves the use of a computer and years of computer tuning experience to work well. Plus, in the past, most EFI systems were very exotic and expensive, making them less desirable for the home builder.

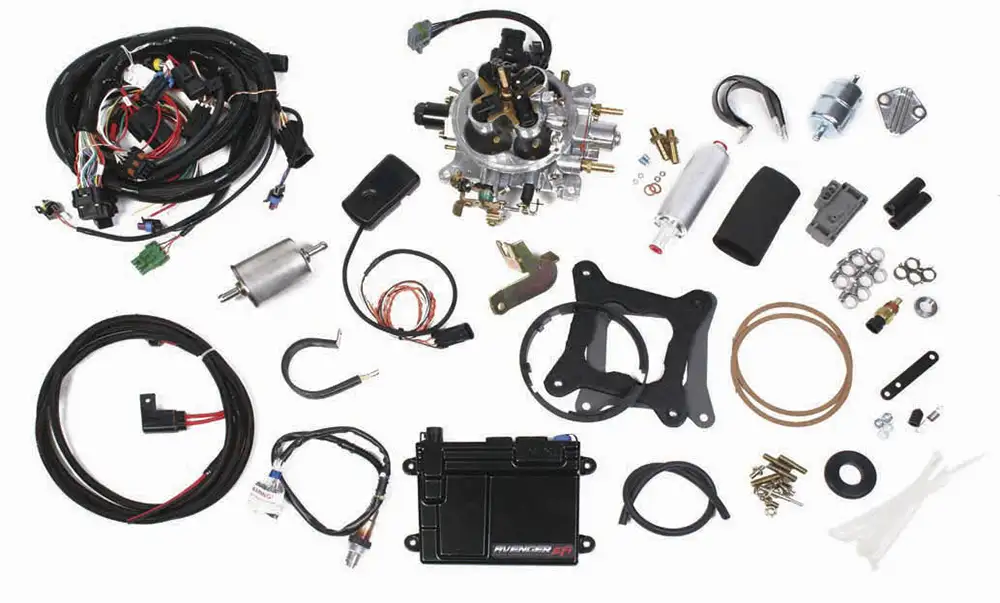

Thank goodness for the guys at Holley, who know a few things about how to get the most out of a fuel system. Their Avenger EFI system was designed for the regular guy to gain all of the advantages of converting their old carb setup to a modern day EFI without a degree in computer science or a second mortgage. As a matter of fact, the Avenger system uses a self learning method, a sort of “artificial intelligence.” Various options for different intake manifold setups and horsepower needs are available as well to ease the process.

Before the initial start up of the engine you’ll need to load the computer with information so that the ECU has a base to begin tuning itself to important variables, including elevation changes, load, ambient air pressure, heat and even your driving habits. The computer, or ECU, then constantly monitors the air/fuel ratio control throughout the engine’s operating conditions for you, supplying an accurate air/fuel mixture to the engine no matter the operating conditions.

Other key reasons to kick the carb is the superior throttle response. With a more efficient fuel/air mix ratio, the intake manifold design can be properly utilized to improve air velocity at the intake valve. This will improve torque and horsepower gains the more you drive it. You can also expect improved emissions as cold engine and wide open throttle enrichment is reduced with this EFI system. Fuel puddles in the intake manifold will no longer be a problem, resulting in better overall fuel economy and improved emissions.

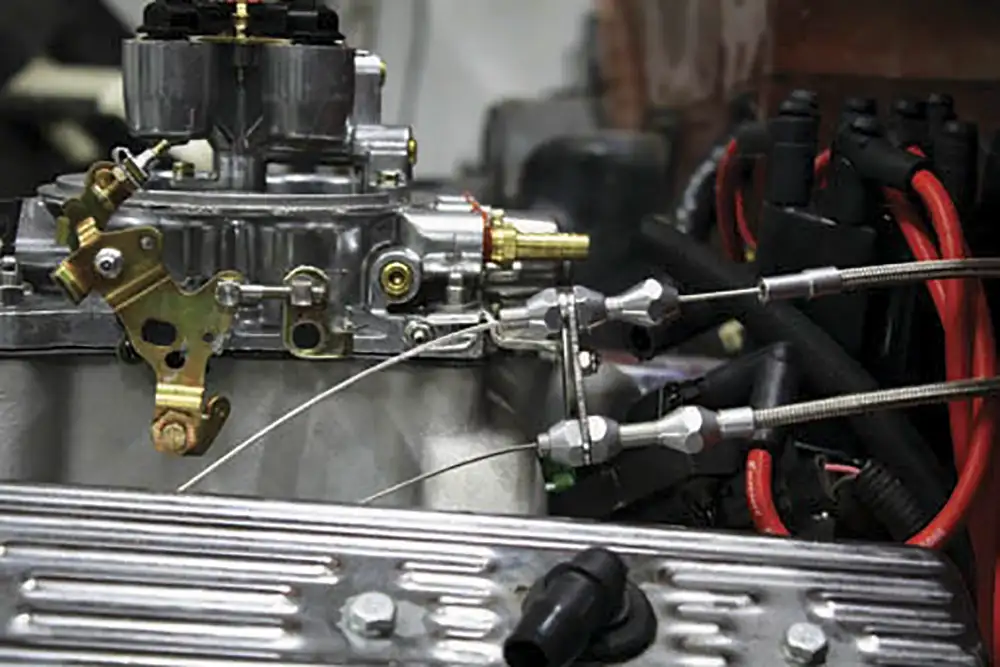

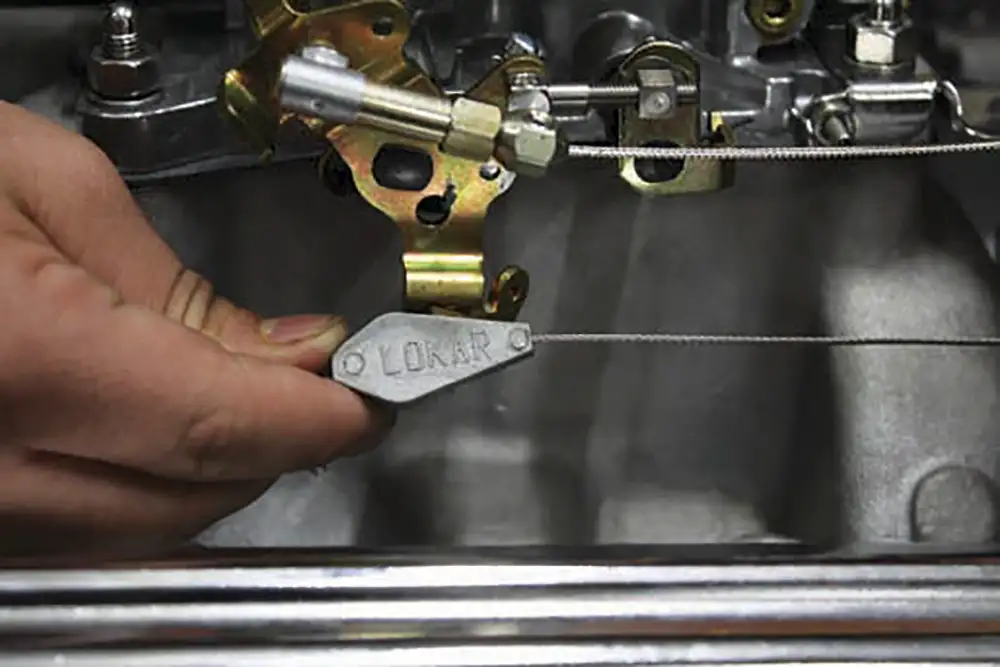

Want to know how it’s all done? Let’s take a look into how to install this Holley Avenger EFI system on a small block Chevy 383 from Blueprint Engines. ST

HOLLEY

Holley.com

LOKAR

Lokar.com

PPC CUSTOMS

121 Sunnyside Ste. 204

Clovis, CA 93612

559.281.8484

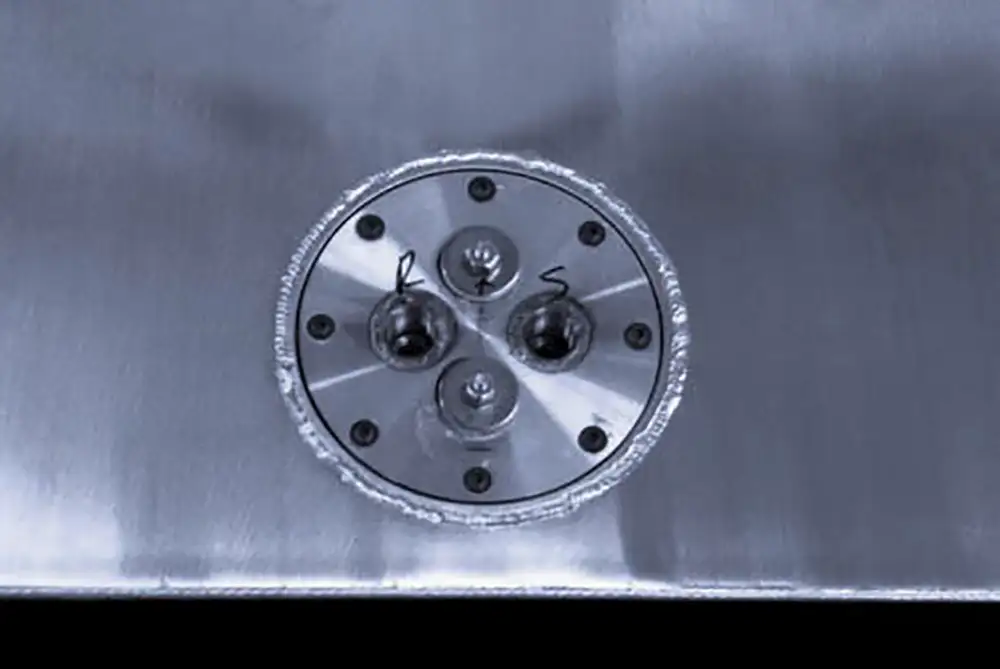

RICK’S TANKS

915.760.4388

Rickstanks.com

SUMMIT RACING

Summitracing.com

Share Link