streettrucks

.

April 16, 2020

.

C10 Builders Guide

streettrucks

.

April 16, 2020

.

C10 Builders Guide

FEW OF US ARE LUCKY ENOUGH to still own the ride we had in high school. More often than not, it’s a simple matter of making the dumb decision to sell our pride and joy to go onto the next shiny thing that catches our attention. It happens to all of us. Well, most of us.

Kyle Hunsaker of Mesa, Arizona, was in it for the long haul with his ’76 Chevy C10, having bought it right around the time he first got his license. Well, actually, this is the second C10 he had in high school—the first was stolen and never recovered, so this was its replacement. Over the years, he has slowly worked on it as time and funds allowed, but Kyle really got down on it after deciding to rebuild it from the ground up. It would take five solid years, but it would be time well spent.

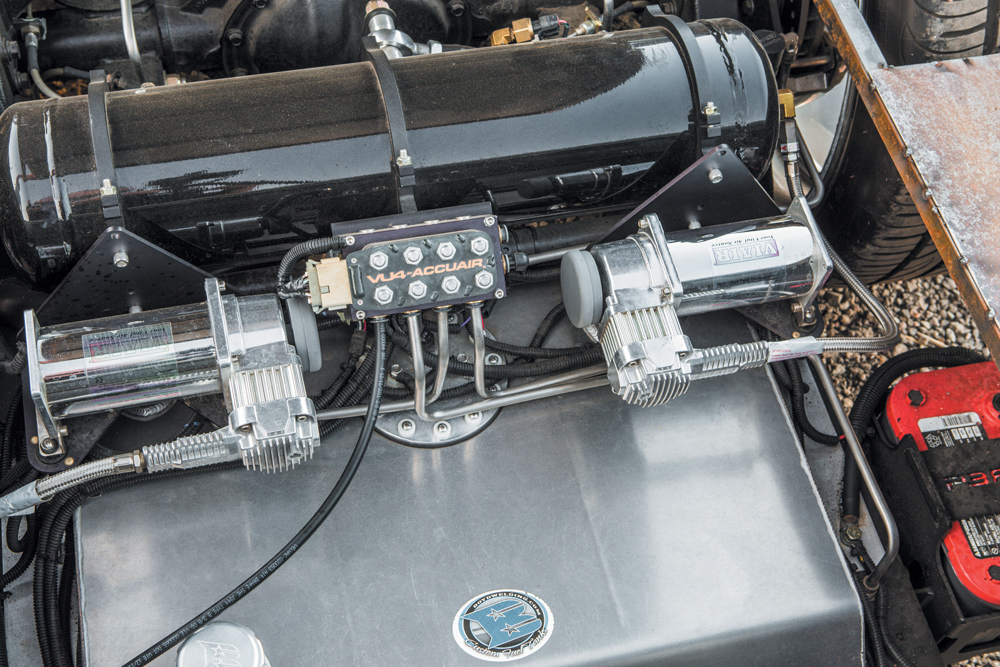

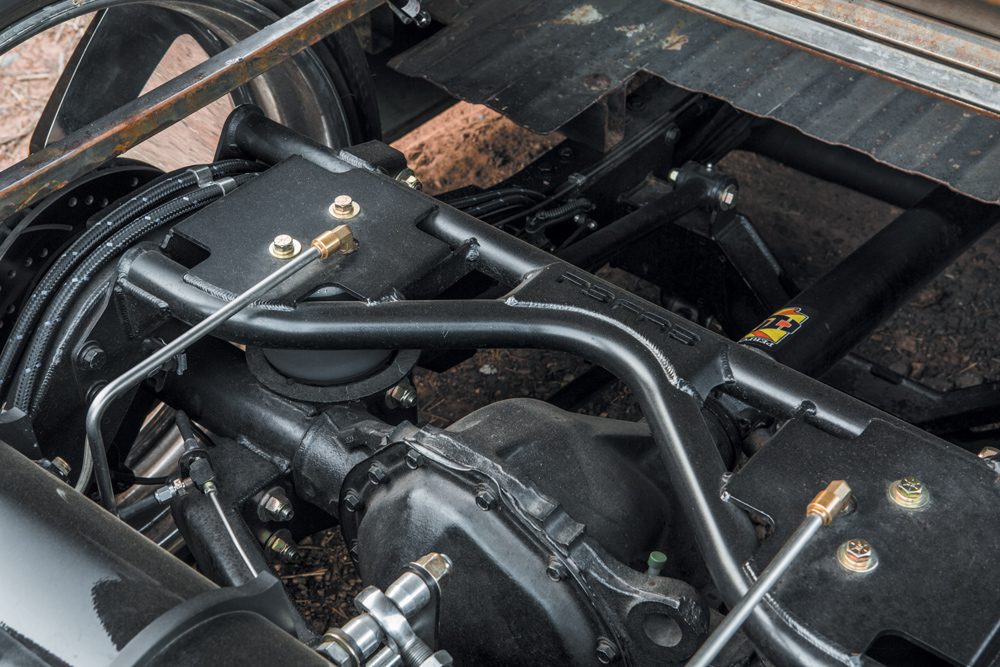

Kyle’s main goal was to have a fun, reliable hot rod, which meant not only having a dependable drivetrain, but a foolproof suspension as well. It didn’t take long for him to decide on a Porterbuilt Level III air suspension setup, which was installed by both Kyle and Justin Heller, who go by the name Build Bros when they’re tackling truck projects together. The Bros pulled the cab and bed off to get unobstructed access to the chassis before installing the Porterbuilt chassis and air ride parts, which went on without a hitch. They also handbent all of the air lines and installed a Boyd’s Welding fuel tank, along with the new fuel lines and even a full Wilwood brake setup up front and on the narrowed rear end. Of course, all of this work was to make sure that the 24×9 and 24×15 Raceline Speedster 5 billet wheels and Pirelli tires would tuck nicely behind the fenders and bedsides, which they did!

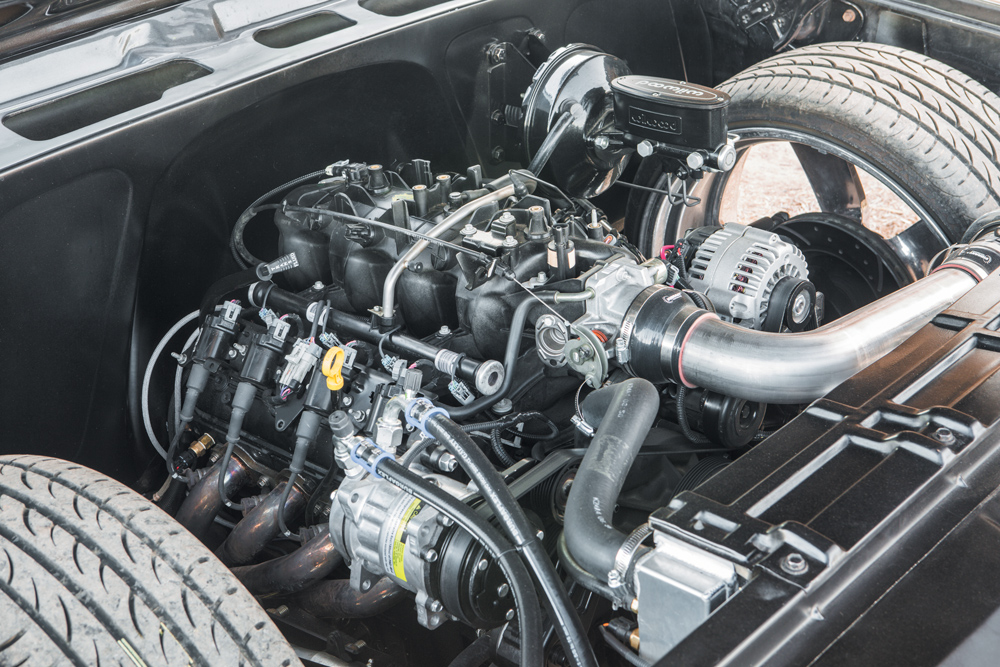

Seeing the frame finally sitting on the ground was all the motivation Kyle and Justin needed to keep going. Kyle had already picked up a 2004 5.3 LS and a 4L60E built by Jason Bowman at Big 10 Garage, so it was just a matter of cleaning everything up, bolting on some Dirty Dingo LS swap mounts, an Ingenuity Fab Shop transmission crossmember, and dropping everything onto the prepped chassis. Slosh Tubz firewall fillers were welded in over at Matador Rod Rod & Customs, which really cleaned up the previously busy stock sheetmetal.

Now, all of this work was done very carefully, since Kyle had already had the truck painted by his buddy Kyle Danielson prior to tearing it apart. With shaved door handles, a molded-in roll pan, and a few other subtle tricks underneath the shiny silver and black paint, Kyle did not want to have to do any of it over again!

Over the years, he has slowly worked on it as time and funds allowed, but Kyle really got down on it after deciding to rebuild it from the ground up. It would take five solid years, but it would be time well spent.

Funny story: When we asked Kyle which specific colors were sprayed, he quickly admitted, “It was just some leftover silver and black paint that Kyle had in his shop!” Talk about using what you’ve got! Regardless, it was just the right combination to give the truck a classy look.

The interior had been done a while back and just needed some freshening up, and it sports something that we wish we’d see more of these days: tweed everywhere! That, in combination with the Zolatone-painted gauge panel and a Budnik steering wheel, and you’ve got a rad retro treatment that oozes nostalgia. The only thing cooler is the Vintage Air climate control, which is a necessity during those hot Arizona summers!

Kyle says that he and best friend Justin learned a lot while working on the truck.

“It was our first big build,” Kyle says. “From building our own brake lines to building our first X-pipe exhaust… [We] built it from the ground up, but we had a lot of help along the way.”

Which, in our opinion, is the best way to build a truck!

Share Link