Bob Ryder

.

May 08, 2025

.

Features

Bob Ryder

.

May 08, 2025

.

Features

If you are into the custom truck scene at all, then you know that a truck’s identity is all about stance. It has to be low. Sure, we see bad-ass custom trucks equipped with airbagged suspensions laying rocker or frame on the deck. When the ‘bags are purged the wheels are tucked up deep into the wheel wells, laying the truck out on its rockers or frame rails. The sight of a laid-out custom ride definitely makes a statement.

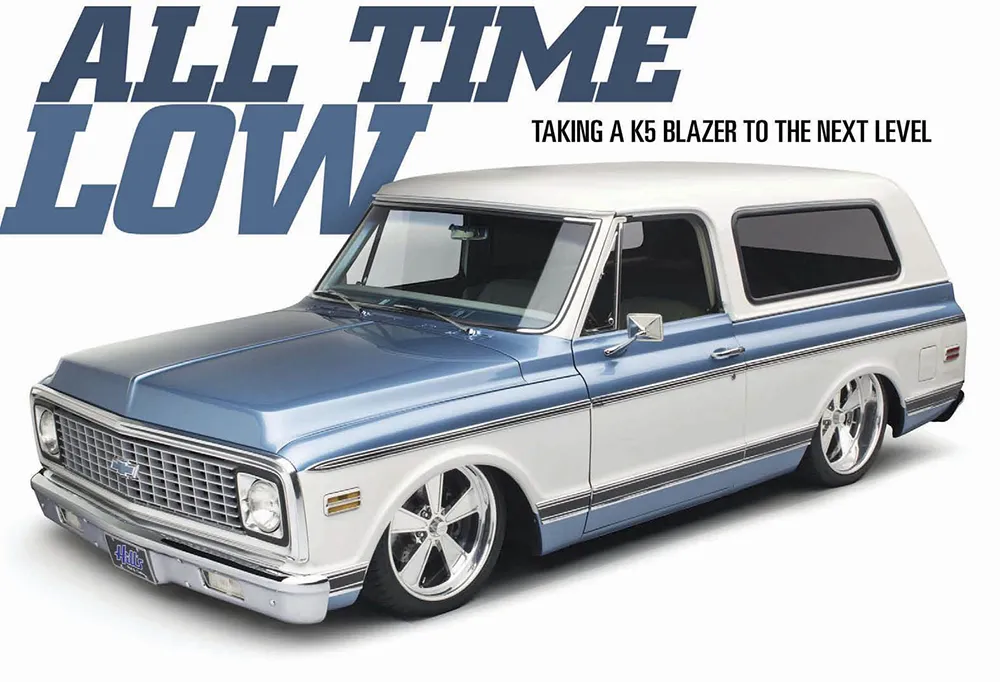

Brett and Katie Alworth from Manhattan Beach, California, decided to build one of those cool low custom trucks, but with a twist. How about a first generation ’72 Chevy K5 Blazer instead of a pickup, and instead of airbags, they thought, why not use coil-over shocks, front and rear, to obtain a constant “All Time Low” stance.

While attending Cal High School in San Ramon, California, Brett drove a ’66 Chevelle. He’s always been into ‘60s muscle cars—weren’t we all. One of his high school buddies, Curt Hill, opened a shop that has become well known in NorCal, Hill’s Rod and Custom (HRC) in Pleasant Hill, California. The two had talked about building a cool custom together someday. Brett, with his passion for muscle cars, wanted to use that theme to build a muscle truck (Blazer). Brett purchased the ’72 Chevy Blazer and his two-year journey began.

His mental impression of a Blazer muscle truck was made real through the talents of rendering artist Eric Reyes. The K5 Blazer body would maintain its factory side molding and trim, mirrors, door handles, windshield wipers, side markers, grille, headlights, front and rear bumpers, gas filler door and side window glass with wing vent. To really maintain the K5 factory identity Brett wanted to paint it two-tone blue and white.

But underneath this factoryappearing Blazer was a completely modified frame, suspension, wheels and tires, disc brakes, engine, transmission and exhaust. Curt and Ronnie Lagorio at HRC removed the Blazer body from its frame. The drive train, wiring and suspension were completely disassembled and removed, and then Curt cut the cross members and used frame rails instead. They were media blasted down to bare metal and boxed. Next, Curt designed and fabricated a tubular triangulated subframe. The modified frame was sent to Maas Brothers Powder Coating in Livermore, California, where it received a magnesium gold powder coat. A front torsion tube was inserted through the frame rails to house the Speedway Engineering 1 ¾-inch-diameter, 48- splined front Sprint Car-style torsion bar to eliminate front body roll. To reduce weight, lightening holes were bored into the torsion bar arms. A Porterbuilt Street Rods coil-over Dropmember was installed, raising the suspension pickup points and components on the frame, making the frame rails the lowest point and eliminating any ground clearance issues. A pair of Porterbuilt 2 ½-inch dropped spindles was sandwiched between the Porterbuilt ½-inch dropped upper and lower tubular control arms. A pair of Strange double adjustable shocks with Hyper coil springs supports the front end weight and delivers the ride comfort and dampening action from the front suspension. Front stopping power comes via a pair of Corvette 13-inch-diameter cross-drilled vented rotors with 2008 Chevy Silverado calipers. The Porterbuilt front suspension narrows the front track width by 1 ½ inches per side for increased wheel and tire clearance. It also moves the wheel and tire centerline forward, centering the wheel in its opening and eliminating tire rub on the firewall. Out back, a tubular subframe structure and cross member were constructed to support the rear suspension pickup points for the ’72 Chevy 12-bolt rearend housing, which was narrowed 4 inches. The rearend housing received all new inner and outer axle bearings and a pair of Mark Williams 31-splined axles with a set of 3.73 gears and a Detroit Locker to ensure both rear tires were getting the power down. An HRC 4-link suspension and panhard bar anchor the 12-bolt rearend housing. To support and dampen the rear suspension, a pair of Strange/Hyper double adjustable coil-over shocks was installed. The rear singlepiston calipers with 11.5-inch-diameter rotors and E-brake came off of a ’78 Cadillac Seville. A Wilwood master cylinder and an MBM 11-inch power booster deliver ample brake pressure to both the front and rear brakes. The Blazer rolls on a set of Intro Speedstar wheels, 20 x 8 front, 20 x 10 rear, wrapped in Nitto NT555 Extreme 255/35ZR-20 front, 275/35ZR-20 rear rubber.

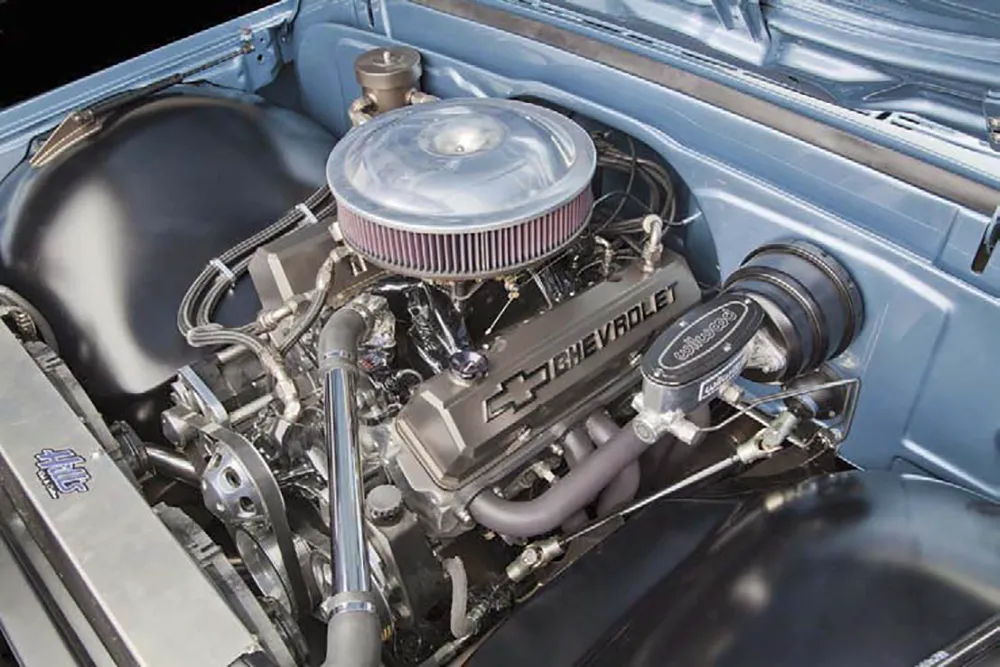

The power comes from a Dart cast iron Chevy 406-ci engine block fit with a pair of Brodix IK210 aluminum cylinder heads. Joe Ortega at Joe’s Engine Shop in Concord, California, performed the machining, assembly and dyno fine-tune of the burly power plant. An Eagle forged crankshaft anchors the bottom end. The internal components and rotating mass were internally balanced with Eagle 6-inch H-beam connecting rods and SRP forged aluminum pistons. To ensure precise synchronization of the crank and camshaft, a Cloyes dual roller timing set and chain were installed and capped with a Cloyes two-piece timing cover. The cylinders were plugged with a set of SRP forged aluminum flat-top pistons and rings. A Crane camshaft was inserted to give the 406 its pulse and rhythm. The valve train rotating mass is linked with a set of Comp Cams push rods, lifters, rockers, valves, springs and guides. Chevrolet Performance aluminum valve covers cap the valve train assembly of the Brodix heads. A Melling oil pump maintains continuous oil circulation of the block and cylinder heads inside a Moroso 7-quart oil pan. A Holley high-volume fuel pump feeds the Holley Pro System 750-cfm carburetor, filtered by a K&N air filter, that sits atop the Brodix dual-plane intake manifold. Electrical energy is produced by an MSD Blaster II coil that delivers the juice to the MSD distributor. A set of MSD ignition wires links the electric impulses to each of the spark plugs. Brett didn’t want the headers to hang below the frame rails, so he had a pair of custom 1 ½-inch-diameter headers built by Carbs Unlimited and Performance in Kent, Washington. The headers collect and flow into a 3-inch-diameter exhaust system muffled by a pair of Borla transverse flow oval mufflers. To maintain cool engine operating temperatures, a Ron Davis aluminum radiator was equipped with dual Spal electric fans. An Art Carr 200R4 automatic transmission with a 2,800-rpm stall convertor was bolted up behind the mighty 406, which is linked to the Chevy 12-bolt rearend via a Mark Williams custom driveshaft. When all was said and done the 406-ci engine produced 495 hp and 510 lb-ft of torque!

Like most bodies that have been exposed to Mother Nature for the past 40 years, the Blazer’s sheet metal was a little weathered. The body was media blasted, which uncovered harsh bodywork on the rear corners and lower rocker panels, all the way from the lower door hinges down. The crew at HRC replaced the lower rockers and rear corners with new NOS pieces, and they did some minor sheet metal work to get the body straight and smooth. Many work hours were invested in the factory fiberglass removable top to smooth it inside and out. HRC made custom inner front fenders for header clearance. Brian Jennings from Bay Auto Body prepped the Blazer body for paint using PPG primer, and then blocksanded the body to perfection. The two-tone color scheme features PPG Marlin Blue and Ermine White waterbased paint buried in multiple coats of clear. Once the paint had cured, the clear was cut, buffed and polished to a deep, glistening shine. To maintain the original factory appearance, an all-new 1972 front grille insert, grille shell and bumper were installed. This model of Blazer didn’t come with upper trim molding, so Brett used molding from a ’72 C-10. Finally, the windows were tinted.

Sid Chavers at Shaver’s Upholstery in Santa Clara, California, did all of the interior stitchwork. The floor, door and quarter panels received a layer of sound-deadening Dynamat before German gray weave carpet was laid out. The custom center console side panels and armrest were covered with light gray leather, while the top was painted the same Marlin Blue used on the body. The Marlin Silver/Blue-painted dash received a padded, light gray leather dash cap. A custom gauge cluster insert was configured and filled with a set of Autometer Ultra-Lite II silver face gauges. The Ididit tilt steering column was also painted Marlin Blue and capped with a 1969 Chevy Chevelle rosewood three-spoke steering wheel. The universal bucket seats and rear seat frames were shaped with high-density foam to replicate factory 1972 Blazer bucket seats, and then covered with paneled, light gray leather.

The crew at HRC kept the audio system simple starting with an equalizer with iPod unit fused into the center console and powered by a JL amp. A pair of 6 x 9s and a pair of 5¼-inch-diameter speakers diffuse the sound. The heavy base was handled with a single 13-inch-diameter JL subwoofer mounted in the passenger side rear corner panel.

Since its debut, Brett’s ’72 K5 Blazer has received numerous awards, including first place in its class at the Grand National Roadster Show, Sacramento Autorama, Goodguys Gazette Pick, Meguiar’s Magnificent Masterpiece and ‘70s Pick. Recently, the Blazer competed in the Optima Challenge autocross and road race competition. Brett would like to thank those who made his vision a reality: Hill’s Rod & Custom, Sid Chavers, Steve Fernando, Maas Bros., Bob Smith and Walker Custom Chrome. ST

BRETT AND KATIE ALWORTH

1972 CHEVROLET K5 BLAZER

MANHATTAN BEACH, CA

Share Link