streettrucks

.

October 25, 2016

.

How to

streettrucks

.

October 25, 2016

.

How to

What many don’t understand is that the proper suspension setup is much more important than the right set of shoes. if the tires can’t make effective contact with the road, then they won’t get you anywhere. Getting the power down to the ground is one important characteristic, ride comfort, clearance, style and safety are others. when picking your suspension setup, all five aspects need to be taken into consideration.

For those who want to go low, there are several options available these days to achieve the look you desire. If you are going for a mild drop, a set of spindles or springs can help out, and they can also be combined for a deeper drop. Springs are more inexpensive, and while spindles can be pricey, they offer better ride quality if you keep the factory springs. Another alternative is to set up your truck with adjustable coil-overs for the ultimate in ride control. If you want to go to extremes with how low your truck sits, airbags will definitely get you there. The

added benefit of airbags is an ultra-smooth ride, however, most of these systems are not optimized for handling or high-powered drivetrains.

On the off-road side of things, there are even more solutions because space and clearance issues aren’t as important. Most off-road capable vehicles see much more time on the street than they do in the dirt, so you’ll need to consider how much comfort and performance you’re willing to sacrifice on either terrain in the interest of building a vehicle that best meets all of your specific needs. There isn’t one suspension design that does

everything perfectly—it’s a give-and-take situation—but that doesn’t mean you can’t have a rig that rides and performs great both on and off the highway.

Multiple suspension designs exist, and they all offer certain qualities that make them better for one situation versus another. To properly set up your rig, you’ll first need to know what’s available, how each system works, what they do well, and what they don’t do well. From there you can decide which suspension setup is best for you and how to modify it to better suit your exact needs.

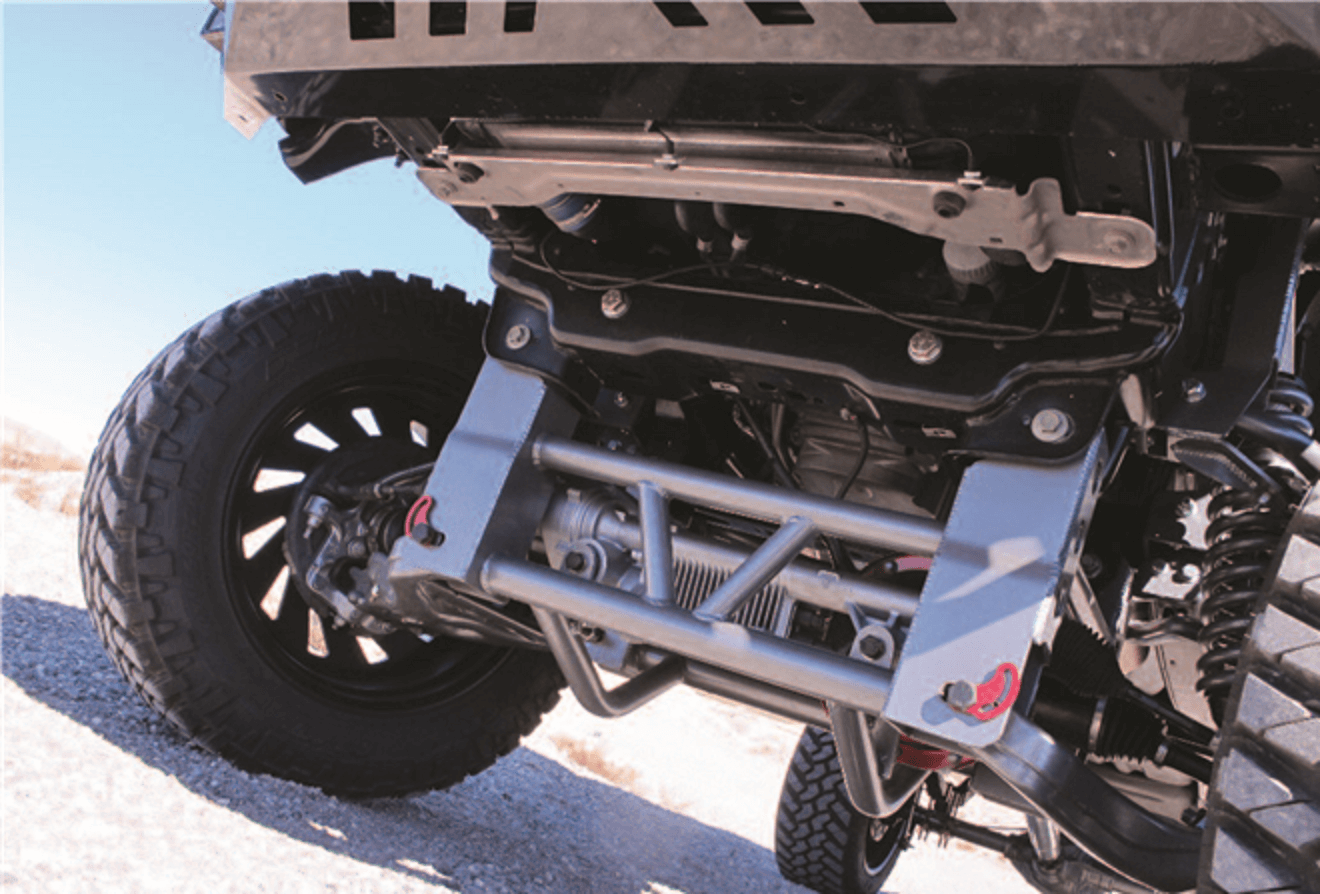

Drop-down brackets are commonly used to gain some ground clearance with double wishbone systems. the one pictured above is an extreme drop-down bracket example; most are only a few inches tall.

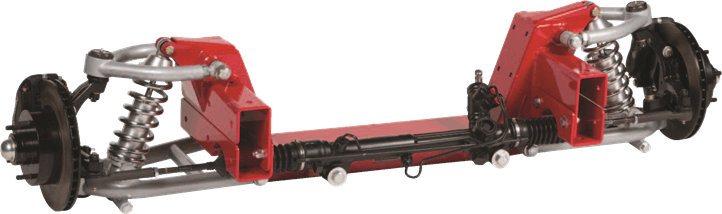

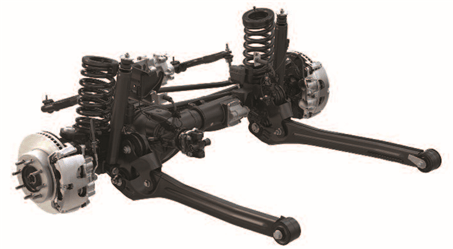

The double wishbone suspension design was and is a total departure from straight axle and is actually a bit closer to a link setup in theory. while the twin beam style was designed to reduce the bump steer of the solid axle design, double wishbone suspension takes it a step further by completely isolating the wheel and tire while keeping its travel perfectly (when designed correctly) aligned to the road, maximizing driver comfort and control.

Utilizing a dual set of wishbones (often called “a-arms” or “control arms”) and a steering knuckle (spindle) in which the wheel is secured, this suspension type keeps the wheel aligned almost perfectly throughout its range of travel. It allows for extremely good on-road manners, but not as much off road in stock trim. The dual a-arms are generally parallel, so when the wheel moves over bumps, the angle of the wheel and tire stays the same and steers straight whether at full droop or full compression. spring types are all over the board here. Torsion springs are the late-model favorite, although coil springs and struts are also in the mix from the oems.

For high-performance long-travel suspension setups, new, longer control arms and custom spindles are the norm. Stock springs are ditched and replaced with coil-overs in most cases. Twelve inches of travel and 6 inches of lift is a common ratio here. Just know that these types of kits are closer to “race-only” designs–on-road performance will be hindered.

Ford created the beam suspension design, and it was revolutionary when it was released. Modifying involves dropdown brackets and springs for light to medium off-road use. All-out race systems use new, longer I-beams and radius arms as well as coil-over shocks.

Ford’s twin beam (I-beam for 2wD, twin traction beam for 4wD) suspension is a true HD truck suspension and was available in rangers, Broncos, e-Vans and F series trucks. It was originally designed to reduce bump steer in vehicles that had previously used a solid axle, 2wD or 4wD. It’s a sort of happy medium between a full solid axle, which handles heavy loads extremely well and works well in the dirt, and a-arm suspension, which handles great on the road, but not as well with heavy loads or in off-road situations. Currently, no late-model vehicles sold after 2014 use this suspension design; the 2wD e-Vans were the last ones in production.

The twin beam can be best thought of as a single “L” frame: the bend in the “L” is where the wheel mounts, and the other two sides are pivot points that are mounted with bushings to different parts of the frame. One pivot is secured under the motor mount on either side, and the others are mounted under the passenger and driver doors, respectively. By making either of the two sides longer, the amount of usable wheel travel can be increased upwards of 30 inches of travel.

Twin beam suspensions are a favorite of high-speed desert racers due to the ease of getting huge amounts of wheel travel at lesser cost than with a-arm designs. Plus, since they were originally designed to handle very heavy loads, the steering and other parts are built robustly enough from the factory to handle harsh desert terrain at very high speeds. Drawbacks for this type of suspension design include uneven tire wear

and unstable camber throughout the suspension’s range of travel.

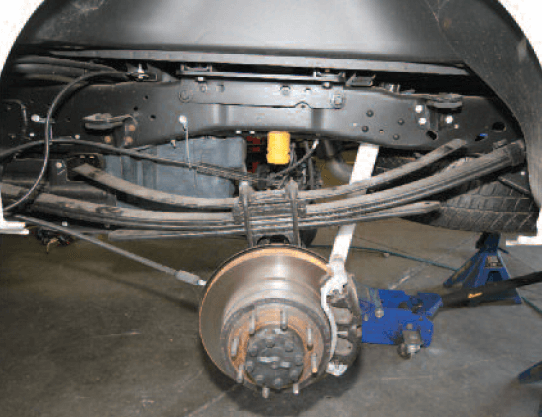

Solid axle, leaf-sprung suspension is the cheapest and easiest way to get decent results. Henry Ford used solid axles for his model t as far back as the early ’20s. They were done differently than they are today. The leaf spring was mounted transversely; in other words, it was a single sideways-mounted leaf spring. Obviously, it’s no longer a new design since it’s been around for almost a century and has undergone multiple rounds of upgrades and tweaks since its inception. Nevertheless, they work great off road, and even with the fair amount of bump steer they have, they do pretty well on road, too. Plus, they can handle substantially more weight with fewer problems than other designs. This is why we see solid axles under most suVs and every size truck. However, suspension systems for solid axles are many, and they all have their own strengths and weaknesses. there are individual ways to modify them, as well.

“THEY CAN HANDLE SUBSTANTIALLY MORE WEIGHT WITH FEWER PROBLEMS THAN OTHER

DESIGNS. THIS IS WHY WE SEE SOLID AXLES UNDER MOST SUVS AND EVERY SIZE TRUCK.”

“IN THE REAR, BLOCKS CAN BE USED THAT SIMPLY PUT A SPACER IN THE SUSPENSION, RAISING OR LOWERING THE VEHICLE BY WHATEVER THICKNESS THE SPACER IS . . .”

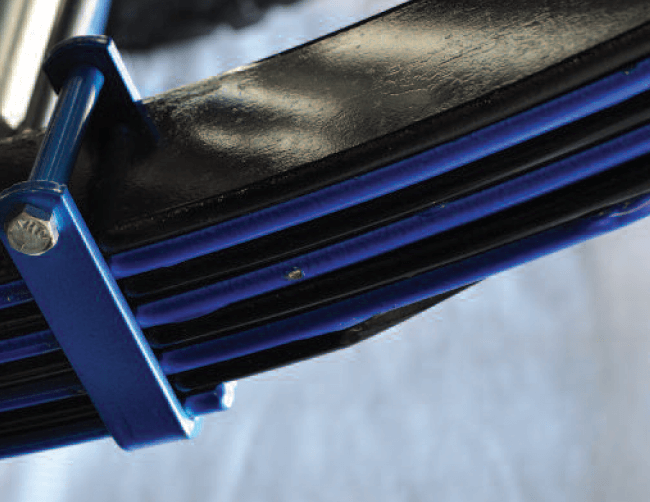

By far the simplest design and cheapest to modify, leaf springs are just multiple pieces of spring steel (a steel with memory that returns to its original shape after being deformed) stacked in varying widths (rates) or amounts of leafs depending on the need. the axle is usually mounted to the center of the leaf, and the frame secures both eyelets of the spring: one solid mounted and the other with a shackle to allow for suspension travel. stock leafs

generally have a main pack that allows for a pleasant ride during normal, unloaded daily driving. Below that spring (and sometimes above it) is an overload spring that takes over when the vehicle is loaded. It’s a much more robust spring designed to come into play only when the rig has a large load on or in it.

Altering height with a leafsprung suspension is simple: In the rear, blocks can be used that simply put a spacer in the suspension, raising or lowering the vehicle by whatever thickness the spacer is; although, these blocks will create added axle wrap under acceleration, wearing out driveshaft components or worse. the use of blocks should be kept to just a few inches in lift, anything higher and you should consider getting new leafs made, adding a leaf to your existing pack, or having your existing leafs rearched by a qualified shop.

Drawbacks to leaf-sprung solid axles are mainly a lack of tuneability when compared to 4-link setups (see “multi-Link suspension” below). Axle wrap is also a concern but can be rectified with a set of traction bars fairly easily.

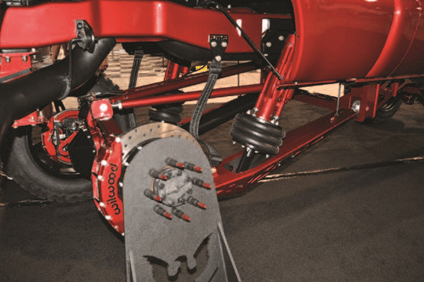

This is where it gets interesting. Four-links, 3-links, radius-arm and triangulated-link setups are the ultimate way to tune your rig’s suspension. a link suspension consists of multiple solid arms, which connect the axle to the

vehicle with some sort of pivoting joint. the axle can then move freely with little restriction within the limits that the links set. the solid links will also keep the axle aligned exactly how you want it to be, at any point in the suspension’s travel, no matter the engine load. springs (air, coils, coil-overs, hydraulic arms, etc.) of any type are used to keep the vehicle at ride height.

Due to the solid links and free choice of shock-and-spring combos, this type of suspension is the most

tunable for any terrain or situation. with a little know-how, it can literally be set up to do just about

anything. adjusting things like the angle and/or the length of each link will affect how the vehicle reacts to acceleration, braking, turning, size of terrain, high-speed performance, low-speed performance, etc.

With multi-link suspensions, you’ll need some sort of lateral stabilization.

Without reinforcement, the suspension could slide right out from under your truck. a good way to combat this is with link bars that are mounted at an angle known as a “triangulated system.” If the bars are straight back and forth, you can use a simple pan hard bar.

Spindles are one of the better ways of altering your truck’s height because they don’t mess with ride quality. Factory systems are set by highly skilled engineers to have the most comfortable ride while keeping good traction. Lowered or lifted spindles change the location of the wheel-mounting point and alter the height. though they are more expensive, they will give the best ride. the only drawback is that you are limited by how much they will change the height. If you want to go lower or higher than the spindles allow, you must combine them with other parts like springs and shocks.

For the ultimate in side-to-side control, a watts link will do the trick. Unlike pan hard bars, watts links won’t pull the rearend from side to side when the suspension travels up and down.

This is a combination of tuned shocks with specific springs working together for the perfect combination of ride

control and handling. these are also adjustable in length and will allow you to get the exact height you want. there are also plenty of them that allow you to adjust the shock valving for the best firmness. Installing a set of coil-overs is always the simplest choice since most are universal and must be adapted for use. If you can make them fit or have it done for you, they are a great option.

If you want the ultimate in adjustability and smooth ride, airbags will get you there. the best way to use airbags is to combine them with a decent set of shocks to prevent a balloon-like ride. Airbags also need to be adapted and can be very reliable if set up correctly. These are not the best option for performance vehicles because they’re too soft and can lead to traction loss. there are some that integrate shocks for better control, but they are a compromise.

There are many different types of shocks that can get the job done. the most common are twintube and mono-tubes. twin-tubes are most common and use an outer reservoir to store hydraulic fluid and low-pressure gas. these can offer great passenger comfort, but under heavy use churning and foaming will occur, reducing their

effectiveness.

A mono-tube uses a single valve on a larger moving piston and has a second independent piston that separates the fluid from high-pressure nitrogen gas. thus, the gas and fluid never mix, making for improved handling and continuous effectiveness.

The previously mentioned shocks might work great on street applications, but when the majority of your driving is over rougher areas or off-road, they may not be the best choice. the problem occurs when the shock piston is overworked, causing the fluid to heat up, sacrificing performance. reservoir shocks can help because they have an external chamber that increases fluid capacity, keeping temperatures down. there are two types: one is a piggyback reservoir shock with attached chamber, and the other is a remote reservoir shock with a loose chamber, which affords more mounting position options.

The ultimate in off-road performance, dampers are bypass shocks that force fluid through external tubes

and meter it via check valve. the benefit of this is multi-staging dampening that coincides with multiple

spring rates. also, if you are off-roading, you will have larger diameter tires that can cause excess vibration in your steering system. this movement can also be controlled with shocks called “steering stabilizers.”

This part is simple yet very effective in minimizing the body of your truck. sway bars are u-shaped tubes of

steel that bolt both sides of the suspension to the frame. these use stiffness to deflect torsion between the two sides of the suspension system. though these are great for on-road vehicles, some off-roaders choose not to use them for the sake of having more independent travel at each corner their truck.

Editor’s Note: A version of this article first appeared in the August 2016 print issue of Street Trucks Magazine.

Share Link