DEVAN ENCE

.

August 22, 2025

.

Features

.

DEVAN ENCE

DEVAN ENCE

.

August 22, 2025

.

Features

.

DEVAN ENCE

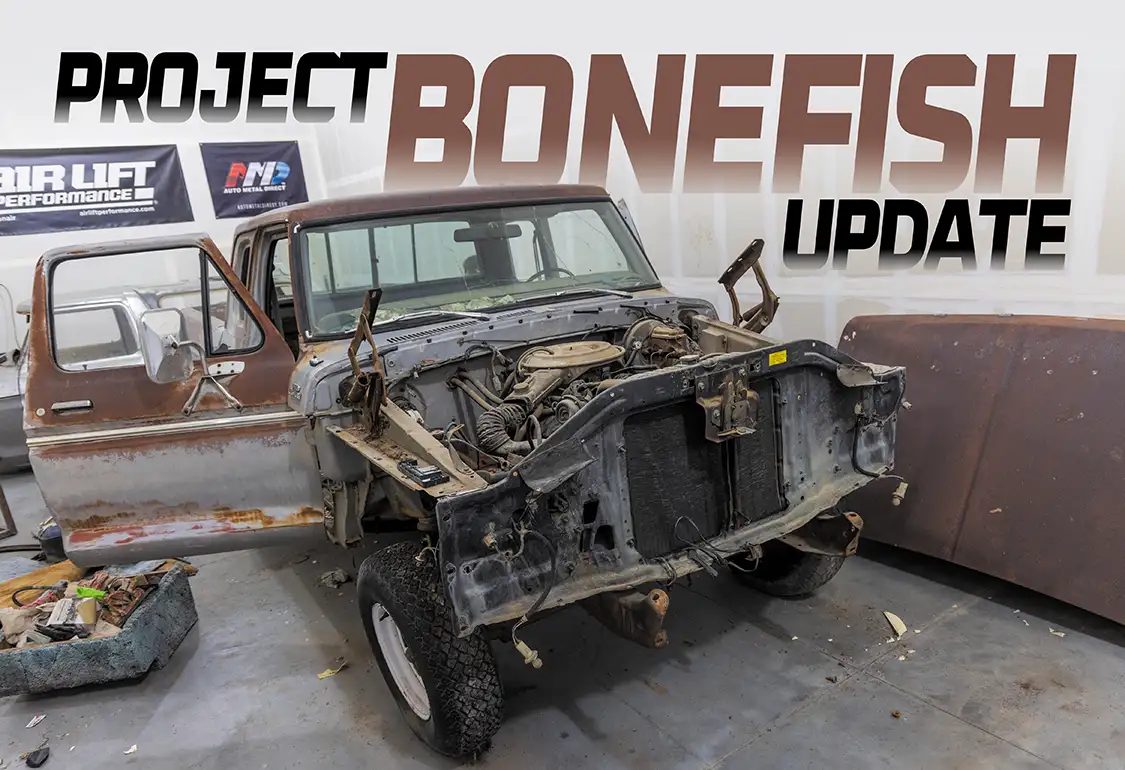

Emmett and I made a solid amount of headway on Project bonefish since you last saw the build. We left off with interior teardown almost finished and the beginning of the teardown on the exterior.

My wife Jasmine decided she wanted to help with the teardown process so she and Emmett finished getting the old carpet out of the cab. Then we worked on getting the dash pulled and all the parts and piece got bagged and tagged as we went. Once all of that was out of the way it was time to ditch the crusty old wiring harness because we will be replacing it with a new one from American Auto Wire when it all goes back together.

With everything out of the cab we sanded the floor and got it sealed with POR15 Rust. This is something I like to do on all the trucks I build just to have a solid base before all the sound deadener and new interior go back into the truck.

Before we pulled the bed I wanted to tackle to rust issues on the passenger side of the bed. I started with the rust over the wheel opening and then knocked out the patch that needed to be done lower rear portion. While I was doing that Emmett worked on getting everything detached from the inner fenders so we could get them removed.

With the rust addressed in the bedsides we got the bed pulled and started work on the back of the cab. The cab corners had started to go in the back on both sides of the truck and needed some small patches done. So, I opened them up and ground the surface rust on the inside, treated and sealed them before welding in the new patch panels.

Now that all the rust issues were addressed it was time to get the cab off the chassis. I had a couple of buddies come over and we were able to get the cab lifted off in no time (one of these days I will have a lift and not need to rely on my friends backs for help, ha ha).

With the cab off we flipped it onto it’s back so I could get the underside taken care of. I expected there to be a ton of surface rust to deal with before it was able to be coated but I was pleasantly surprised. A wire wheel on a grinder, 3” roll lock on my air grinder and a DA made short work of getting the bottom of the cab clean and ready. I coated it with POR15 Rust to get it sealed up and have a solid base under the truck.

I have to say I am pumped that my 11 year son wants to be so involved in the building of this truck and with my wife joining in on the fun it really has become a family project.

There are parts showing up weekly for this build and I can’t to show you what else we have planned for this rad 79 SuperCab!

Share Link