Kevin Aguilar

.

January 05, 2026

.

c10

.

RICH CHENET

Kevin Aguilar

.

January 05, 2026

.

c10

.

RICH CHENET

THOUGH BOB BERTELSEN HAS BEEN ON A HOT STREAK WITH A FEW CAR BUILDS, HE REMAINS A TRUCK GUY AT HEART. HIS FIRST VEHICLE WAS ’76 GMC 4X4 CHEVY TRUCK. He caught the custom bug when he decided to lift it, attach big wheels and tires and repaint it. As life carried on, with marriage and kids, the custom vehicles went by the wayside.

Now that he has more time freed up, he was able to build a ’67 Camaro convertible with C4 Corvette suspension. It was grand champion of the Street Machine Nationals, and took home many other awards. With the success of this car, he built Octane, another ’67 Camaro convertible. His next car was a ’72 Firebird called Code Red, which was a Muscle Machine of the Year finalist and won numerous awards. It was the first car he built for autocross, road racing and speed stop. Next came Brute Force, a ’71 Camaro, which was also a Muscle Machine of the Year finalist.

While having dinner one evening with friend Pascual Marquez of Marquez Designs, Bob decided to tackle a C-10 truck build. Fortunately, Pascual knew of a rust-free project truck that would be perfect, and soon enough it was sitting in Bob’s driveway. After several weeks of bouncing ideas back and fourth, Bob settled on the concept of making it a cutting-edge autocross-style truck.

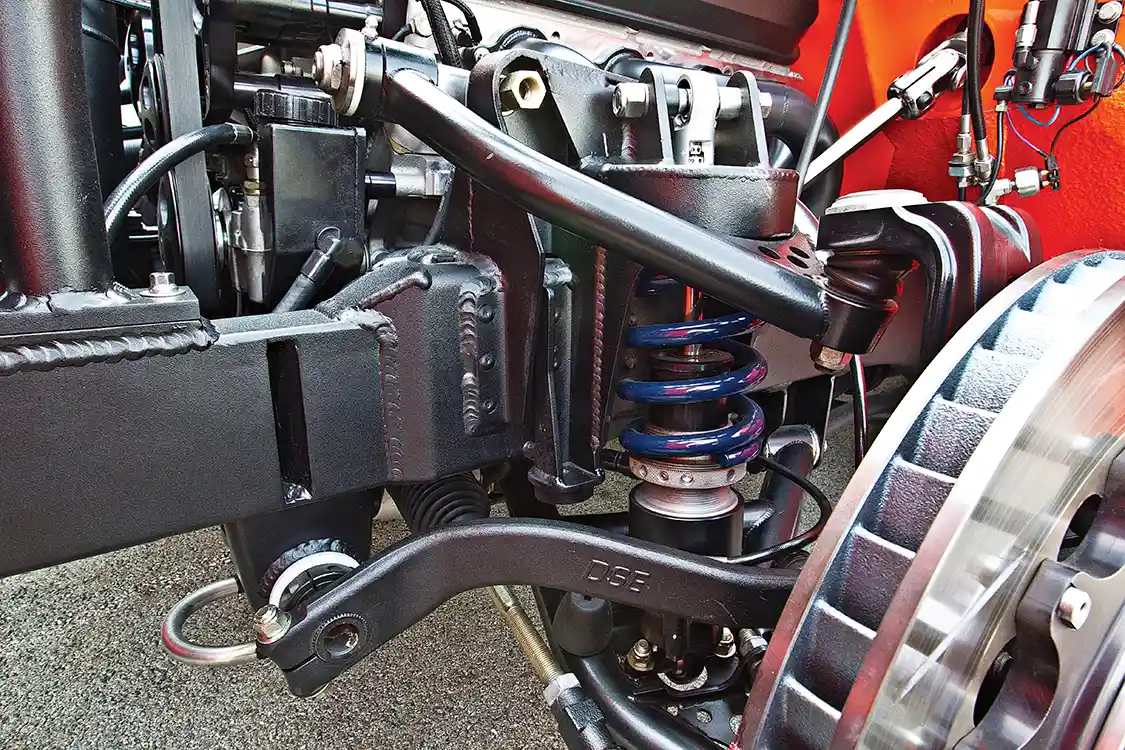

Bob knew he wanted the C-10’s custom- made frame to accept a Detroit Speed Suspension X595 cross member and a second gen Camaro rear QuadraLink. With a little help from the Detroit Speed’s engineers, he got the pick-up points for the suspension and set out to draw the frame in CAD. Then the files were sent out to Hickey Metal Fab to laser cut the rails that feature 2x6x.125-wall rectangular tubing in the center. Once everything was back home, Bob started building and welding in all of the cross members and suspension brackets. He placed the cab on the new rigid frame and fabricated the body mounts.

Next, neighbor Tom McKenzie helped Bob build the full roll cage that ties into the bed and custom frame. Bob bought a hydraulic bender so that he and Tom could quickly fab the roll cage. His friend Mark from Petra Tool and Die machined roll bar ends that allow the front down tubes to be unbolted from the truck and the rear roll bar to unbolt from the cab. Next, it was on to mounting the body panels. First up was the tilt front end. Bob started with a US Body tilt front end, and then used his new bender to shape some 1-inch square tubing to fashion supports for it. With a lot of CAD design, he was able to figure out where the hinges needed to be in order for the front end to tilt with a ½-inch aluminum splitter under the front bumper.

Once this was set up, he started modifying the bumper section of the fiberglass front end for the lower opening. The next modification was the heat extractors on the hood, which was a tricky issue. He made cuts in the hood and used wood and fiberglass to make the pockets. Then he cut out the center grille section and replaced it with a CAD-designed version cut using a water jet. Bob also installed LED marker lights from D&Z Customs in 3D- printed housings. The headlights are JW Speaker LED versions, and Bob customized a pair of Camaro headlight buckets to house them.

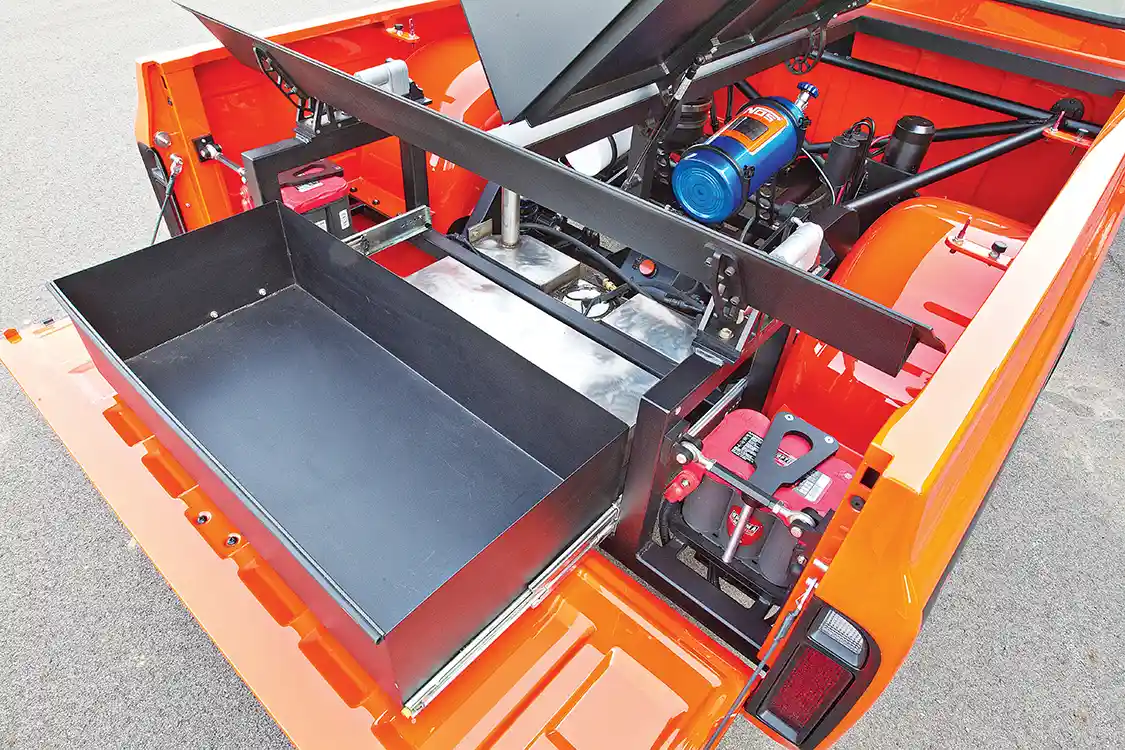

With the hood roughed out, it was on to mounting the bedsides and tailgate. Bob didn’t plan to have a floor in the bed, so the sides had to be hung from the roll bars and frame. Once the bedsides where installed, Bob sent the truck to RPM Hot Rods in Pittsburgh so that the dash and console could be fabricated. When the truck returned, he started fabricating the tonneau cover and rear spoiler. It took a fair amount of CAD drawing to get the spoiler to operate without interfering with the tonneau cover. Once designed, Bob had Humtown Products create the hinges for the spoiler and the tonneau cover using a 3D printer to make sure they worked correctly before he had them CNC milled in aluminum.

Next, it was time for bodywork. Bob put in 60-80 hours a week on bodywork with some help from his friend Rick DeSalvo and his maintenance man Shayne Smeltzer from A Plus Powder Coaters, Inc. While doing the bodywork, Bob spent some time mixing different BASF oranges until he came up with the perfect color, Orange Rush Orange. The final primer was sprayed in his garage, and then the C-10 was shipped to Bonnell’s Rod Shop in Erie, Pennsylvania. The crew jumped in and helped with final sanding, while Bob repaired a bedside that had been damaged in shipping. Bob and Phil, the shop supervisor, sprayed the paint. First, they laid down two coats of BASF White base, followed with three coats of BASF Orange Rush Orange, and then they applied five coats of BASF DC5335 clear.

Bob disassembled the frame and took it back to A Plus Powder Coaters, Inc. The crew media blasted the frame and suspension parts, and then applied a coat of black texture. While Bob and Shayne Smeltzer reassembled the frame and suspension, Bonnell’s Rod Shop was busy wet-sanding and buffing the cab, doors and bedside. About two weeks after painting the truck, Bob took the rolling frame to Bonnell’s Rod Shop and set the cab back on it along with the bedsides.

Back at Bob’s home shop, Shayne started the wirin which dyno’d at 648 hp at the flywheel. It was mated to a dual-disc carbon clutch with an LS hydraulic throw-out bearing coupled to a Tremec T-56 Magnum that Mark at Bowler Performance had upgraded. Bob also installed Baer 6R 14-inch brakes and plumbed the lines along with JRI adjustable shocks with hydraulic lift cylinders, which would allow the truck to be raised 2 inches to get into a trailer or to fit a jack underneath without affecting the performance of the coil-over.

While the truck was being assembled, Bronson from Humtown Products created the door handles and hood louvers using a 3D printer. Once all of the body panels were lined up, Bob took the truck back to Bonnell’s Rod Shop where he laid out tapelines for the black sections of paint. Bob’s daughter Angela designed the “Orange Rush” logo, and they decided at the last minute to add it to the hood and tailgate. Bob and Phil applied the BASF Black base and two coats of satin clear.

Helping out the interior, RPM Hot Rods upholstered the Recaro seats in black leather with orange stitching, along with the dash, door panels and console. Then the truck was sent to Hutter Performance so that the motor could be tuned to push 529 hp at the rear wheels. Bob and Shayne finished the truck at noon the day they needed to leave for the Goodguys Nashville Nationals. With zero miles on the engine, they loaded it into the trailer and planned to run it in Nashville to break it in before the event. Traffic delayed them, so when they stopped to fuel the rig, Bob pulled Orange Rush out and made a 2-mile test run. The next day they competed in autocross and won. ST

OWNER

Bob Bertelsen

1969 Chevrolet C-10

Columbiana, OH

ENGINE

TRANSMISSION

SUSPENSION

WHEELS & TIRES

BODY & PAINT

INTERIOR

SPECIAL THANKS FROM THE OWNER: To God for the ability to build cars/trucks and my wife for her support.

Share Link