John Mata Jr.

.

July 13, 2023

.

Features

John Mata Jr.

.

July 13, 2023

.

Features

When you’re out at the auto parts store do you ever try to match up the guy in the shop to one of the customized vehicles parked outside? All obvious giveaways aside (a dude wearing a Camaro hat or someone buying one of those “pee on Chevy” window decals), there are sometimes clues that can help make the right connection. Now, before we catch any flack about being creepy, shifty individuals who can’t mind their own damn business, it’s just an all-too-natural thing to do when you’re standing in a checkout line that’s seven deep with customers in front of you who all need to know which new-car scented air freshener actually smells the most like a brand-new car’s interior. A guy needs something to distract himself.

Otto Vega

1954 Ford F-100

Salt Lake City, UT

Shop: Kindig-It Design

Shop: Kindig-It Design

Shop: Kindig-It Design and Painthouse

Shop: JS Custom Interior

One telltale sign that gives someone away is their size—more specifically, their height. One might figure that a taller gent would be stepping into the jacked-up diesel rig that just happens to be taking up two parking stalls outside, or that a shorter guy might feel more at home in something along the lines of a Fiat. Well, neither of those assumptions is too reliable, because we’ve seen guys tall enough to play center for the local junior college basketball team squeeze themselves into body-dropped mini-trucks.

For guys like Otto Vega (who just happens to stand at 6-foot 4 inches), comfort is everything, but he isn’t one to sacrifice his taste in vehicles for the sake of skating around in cars and trucks that don’t resonate with his personal taste. He has come to grips with the fact that cars (old and new) just weren’t, aren’t and never will be designed with his size in mind. His solution? We’ll get to that in a moment. It wasn’t until he met a certain group of customizers that the answer became clear as crystal.

Otto had been in contact with Dave Kindig of Kindig-It Designs about checking out a ’72 Datsun 240Z they had up for sale. Upon arrival, he gave the car a good look, and the two talked about other vehicles and projects that might also be of interest. Otto had mentioned that he had a 1954 Ford F-100 that had been sitting in his garage for a few years and that he had strong intentions about ripping into one day.

His very first vehicle was a ’55 Ford pickup, so he just had to get another one that was similar to the one he owned years back. As the visit progressed, Otto and Dave struck up a deal, but not about the Datsun. They had come up with a plan for the ’55 instead. Otto jumped on a spot on the shop’s waiting list, which was a solid year at that point. The truck was shipped to Kindig-It Designs as soon as he got back home. Then the truck sat in the shop for a year before they began any work on it. From there, the Kindig-It crew spent 12 months custom-tailoring the Ford to Otto’s precise measurements.

Not only does the truck feature highly innovative design work and execution, it also maintains that classic nostalgia from Otto’s youth that he was trying so hard to capture with this build.

Okay, maybe that last line sounded like hyperbole, but it really wasn’t. Of course, the truck’s body modifications were shaped to what Otto had in mind, but the truck was actually stretched in length to better fit his stature. The Ford was personalized in a way that most trucks aren’t, and it was all done to achieve a truly custom level of comfort and performance. “Otto wanted to build something he could get in and out of and sit in comfortably,” says Dave Kindig of the truck’s most understated yet huge modification.

“We modified the Ford to fit his 6-foot-plus frame, and we had to do it in a way that didn’t look like we simply stretched the truck in overall length, which would have looked odd and disproportionate. Instead, we got the extra length we needed by moving the firewall forward and stretching the wheelbase 8 inches overall: 4 inches through the doors and moving the axle forward 4 inches in the front gave us the extra room we were after.”

A comfortable fitment only made up half of the equation for creating more room, however. Otto drives his vehicles as they were intended to be driven—hard. And if he doesn’t sit comfortably and doesn’t have adequate space for quick movement, he would be unable to utilize every bit of the performance capabilities his truck has to offer. “Otto is the type of guy who likes to do 120 mph on the turnpike by his home, so the idea of giving his truck the power as well as the space he needs to take advantage of its handling were both equally necessary. We wanted to make sure he could utilize both comfortably,” Dave adds.

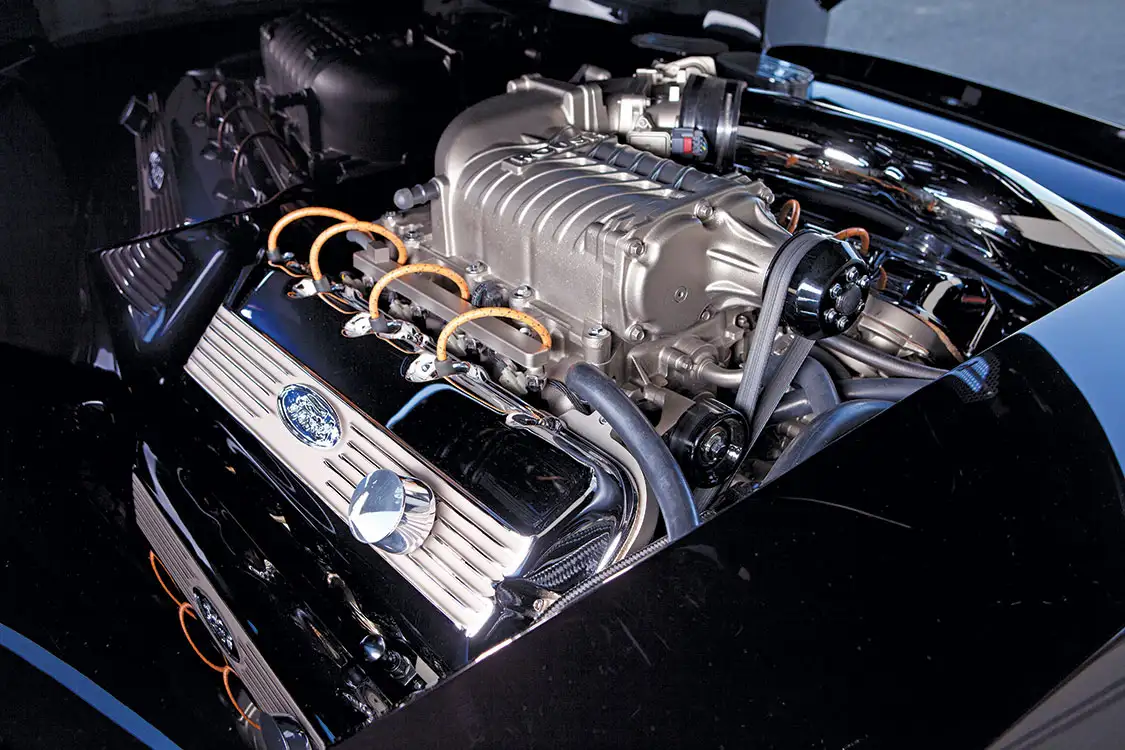

But extra legroom is just where the impressive nature of this truck begins. The performance that Dave briefly touched on revolves around the F-100’s power plant, a supercharged 5.0L Ford Coyote engine from Roush Performance. The Bowler 4R70 performance transmission harnesses the engine’s stable of 625 horses with ease and lets Otto rip the truck down the highway at eye-watering speeds.

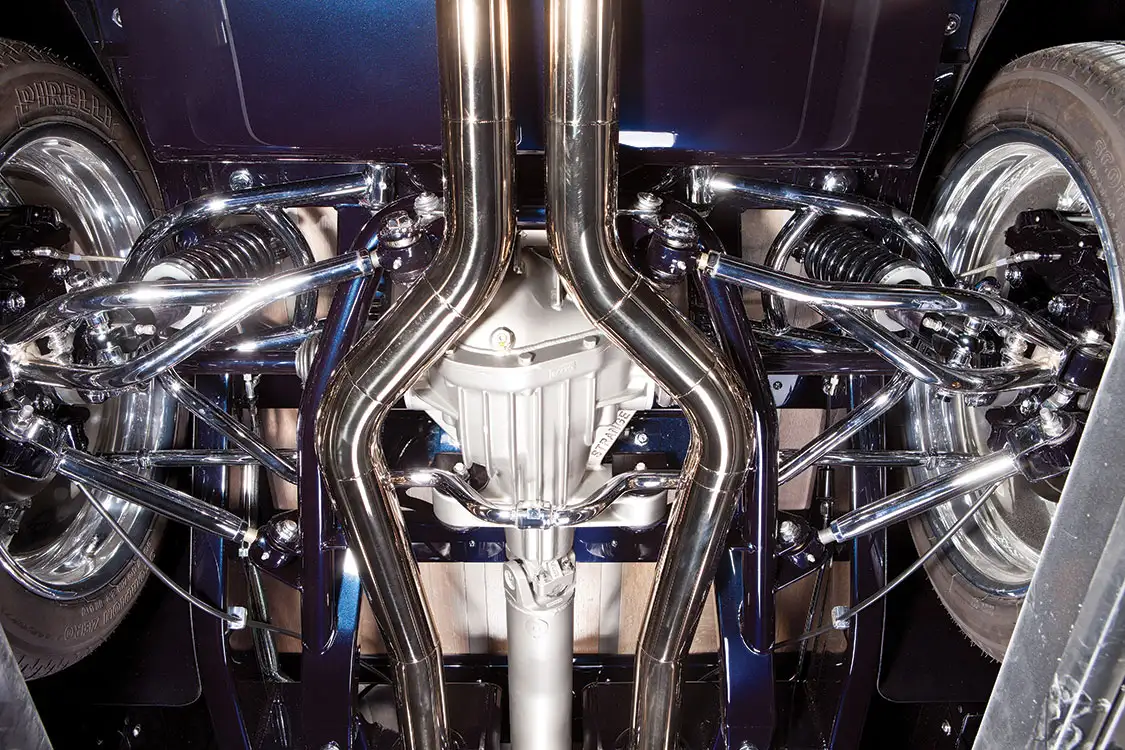

There isn’t one inch of this truck that hasn’t been customized in one way or another, and that is something anyone can see from clear across the street. The interior is out of control, the body mods and paint are as trick as can be, and if you’re lucky enough to catch the truck aired up, you may be able to get a glimpse of the chassis and undercarriage, which is kept absolutely pristine.

Otto could consider himself lucky if he didn’t find crowds of gawkers surrounding the truck at all times. These would be the people who skip right past the guessing game of matching up drivers to their potential rides and shoot straight for waiting around in the parking lot to have the opportunity to shake the owner’s hand. We can respect this sentiment, but this is assuming that Otto would even dare consider leaving this masterpiece unattended while out mixing with the general public. Some vehicles are best kept in gear with a driver sitting and ready to jet at any given time.

“We helped build Otto’s truck to fit somewhere in the ‘farm truck meets supercar’ category,” Dave goes on to say. If you haven’t dreamed of such a fusion, here is a physical example to help get an idea of what the mash-up could look like. Not only does the truck feature highly innovative design work and execution, it also maintains that classic nostalgia from Otto’s youth that he was trying so hard to capture with this build. Purists as well as those looking to push boundaries with vintage vehicle projects are sure to fall in love with everything this truck stands for.

Editor’s Note: A version of this article first appeared in the December 2016 print issue of Street Trucks.

What role does Dave Kindig play in the design process of each car?

Dave Kindig is the driving force behind each car’s design at the shop. His process begins with crafting a detailed sketch, which serves as the foundation for every build. These artistic blueprints, meticulously drawn by Dave, are a testament to his creative vision and expertise.

When you look at the collection of these sketches displayed on the art wall, it becomes clear just how many unique and innovative cars have been brought to life over the past 25 years. Dave’s role is pivotal, turning initial concepts into stunning, one-of-a-kind vehicles.

How does Kindig-it Design handle the interior work for their custom cars?

Kindig-It Design ensures exceptional interior craftsmanship for their custom cars by collaborating closely with JS Custom Interiors. This partnership simplifies the process thanks to their shared location, which allows for seamless coordination and quick adjustments.

No effort is spared to ensure the finished product meets the high standards Kindig-It Design is known for, resulting in interiors that perfectly complement the custom-built exteriors.

What is the connection between Justin Stephens of JS Custom Interiors and Kindig-it Design?

Justin Stephens, the expert behind JS Custom Interiors, is integral to the interior work at Kindig-It Design. His workshop, conveniently located in the same building as Kindig-It, ensures seamless collaboration between the two entities. This proximity fosters a cohesive workflow, allowing for efficient communication and streamlined projects from concept to completion.

In working closely with Kindig-It, Justin ensures each vehicle’s interior is meticulously crafted to match the high standards of the overall design. His expertise not only elevates the quality of Kindig-It’s projects but also simplifies the logistics, making the entire process more efficient for everyone involved.

Share Link