ST-STAFF

.

June 16, 2020

.

F100 Builders

ST-STAFF

.

June 16, 2020

.

F100 Builders

CUSTOMIZING F-100S has been a popular trend for many decades, but the most coveted generation was the 1953-56 model. These days there has been a growing interest in the “later models.” Specifically, the 1967-72 bump-side F-100s have been gaining traction with custom versions sprouting up at shows throughout the country, and The Roadster Shop team is keeping up with the trend.

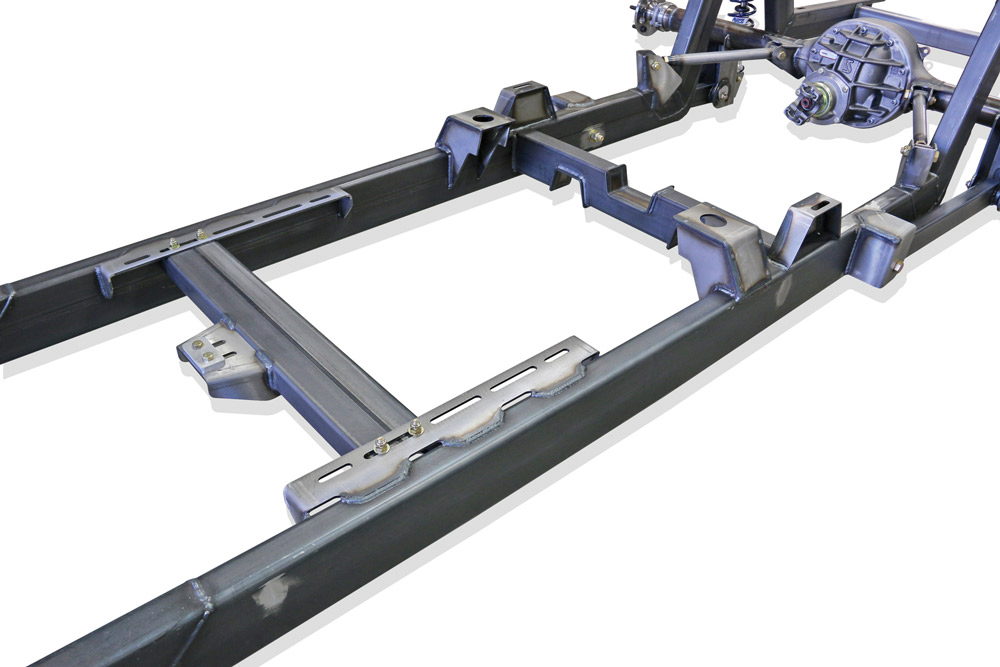

Although The Roadster Shop has offered options for classic trucks for a while, the price tag was a bit steep for most builders. A few years ago, the company used new technology to develop chassis for those on a more moderate budget. By creating a frame that would take less time and labor to form, the Spec Series chassis comes at a lower price point out the door. These chassis have been a big hit with other truck models and now the same components are available to help the up-and-coming bump-side F-100 pickups.

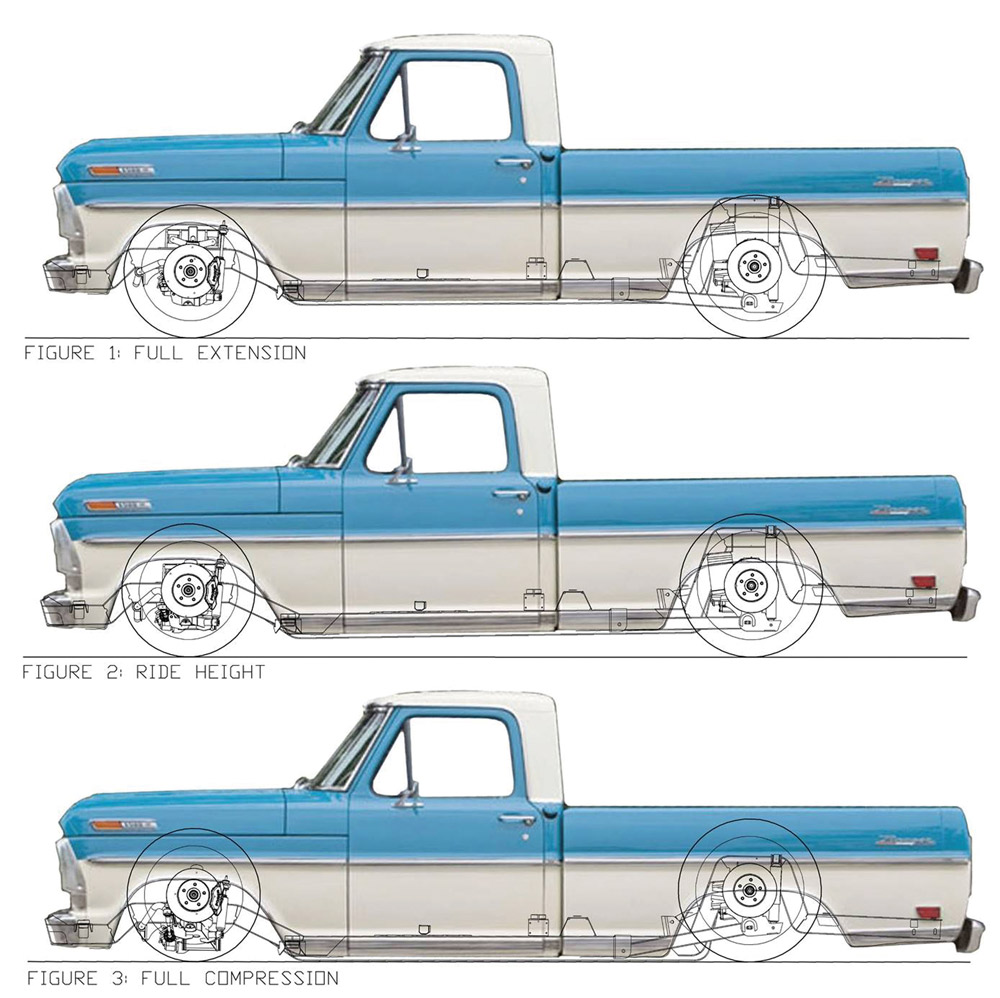

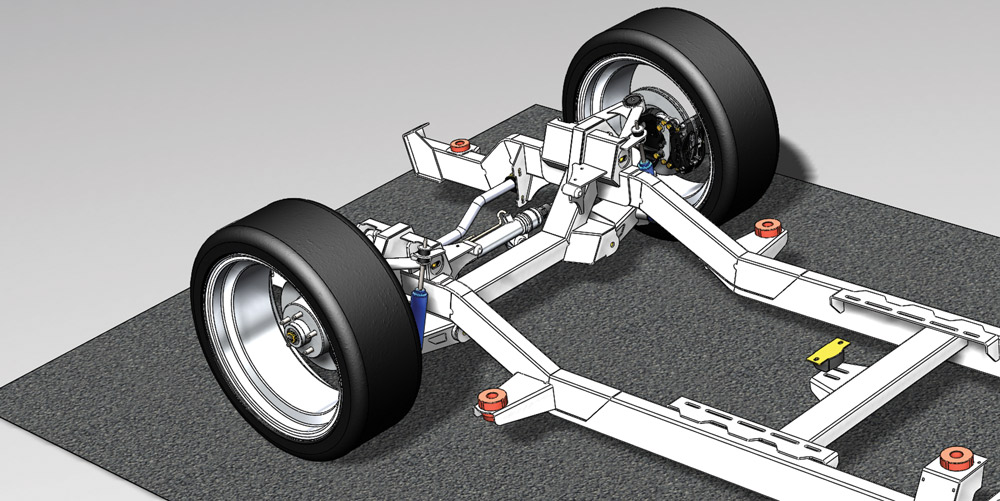

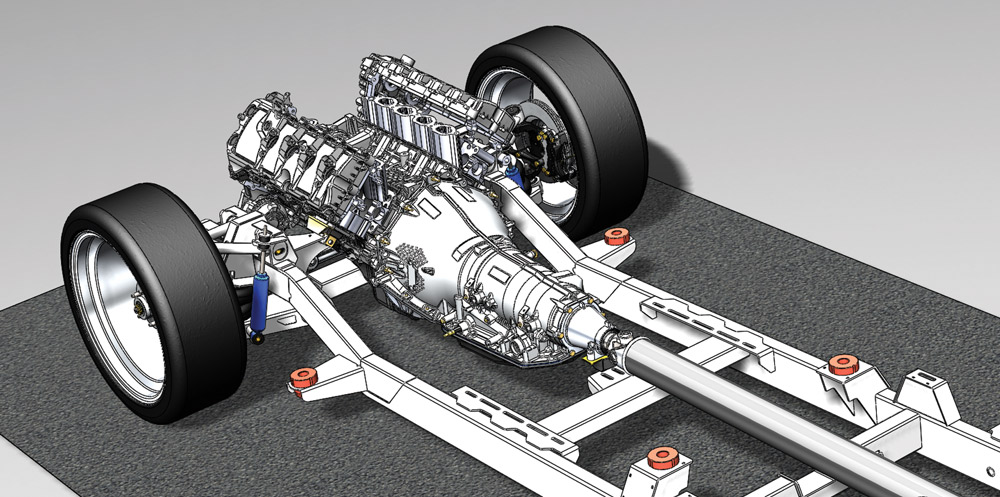

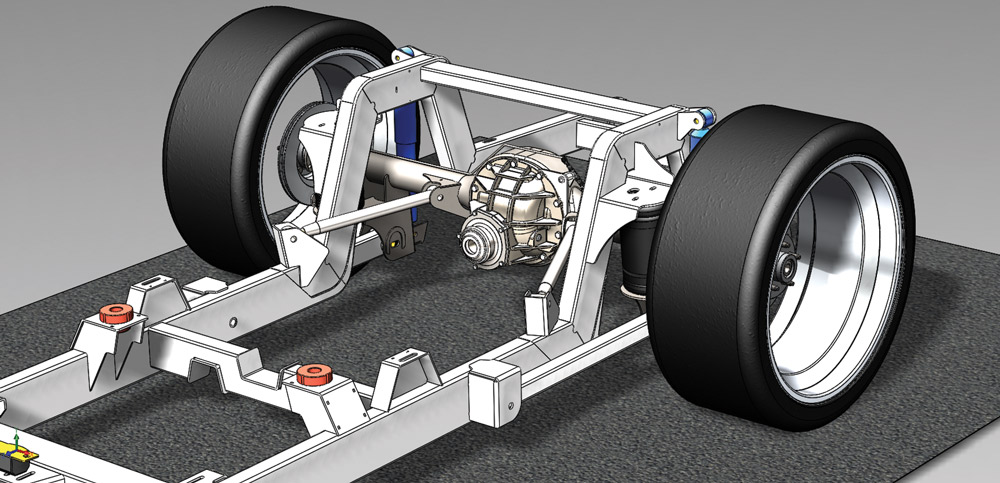

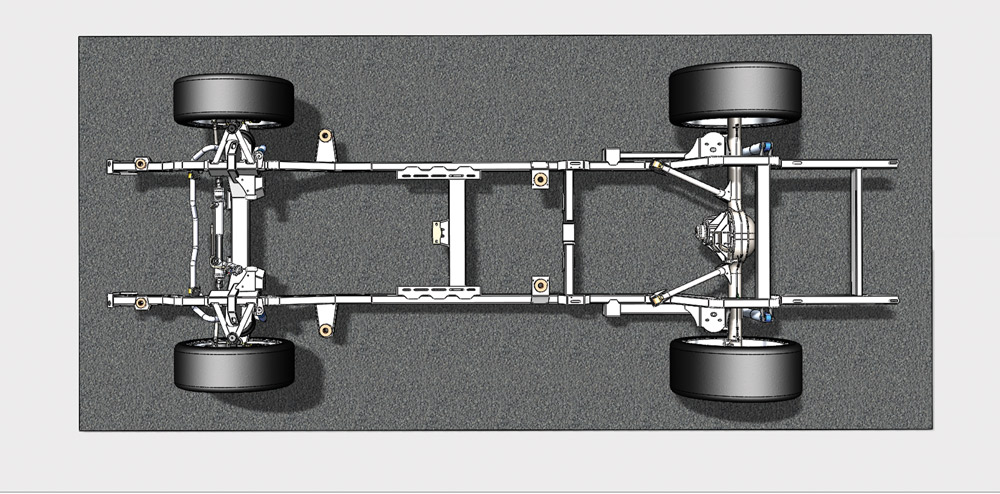

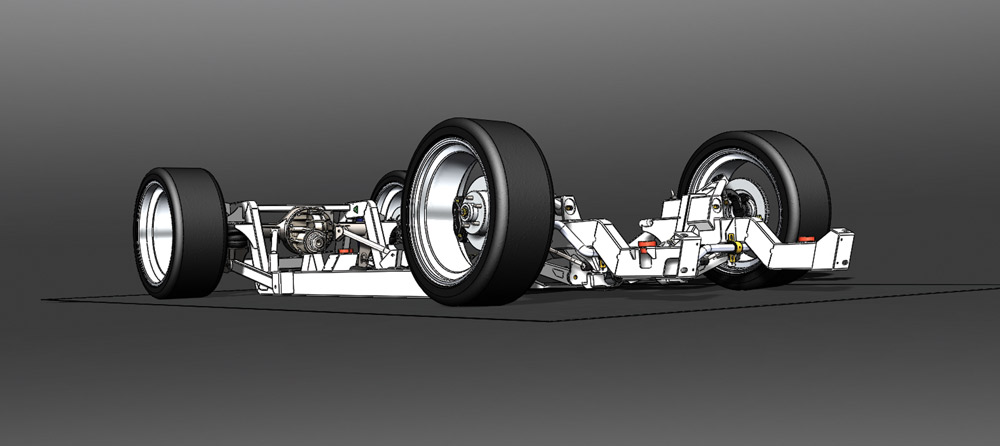

Getting things rolling, the Roadster Shop 3D scanned one of these trucks and uploaded the data to a computer. From there, the team was able to develop a frame and chassis to make it go low on Strange Engineering coil-overs or lay the body on the ground with airbags. After the computer-modeled chassis was created, it was tested with a special suspension program to simulate how it would react under real driving conditions. Once they were happy with the design, the team pressed the “print” button and a real version was printed in 3D and ready for assembly. Afterwards, it was installed and driven on the streets to get real-world feedback on performance, and it did its job just as expected.

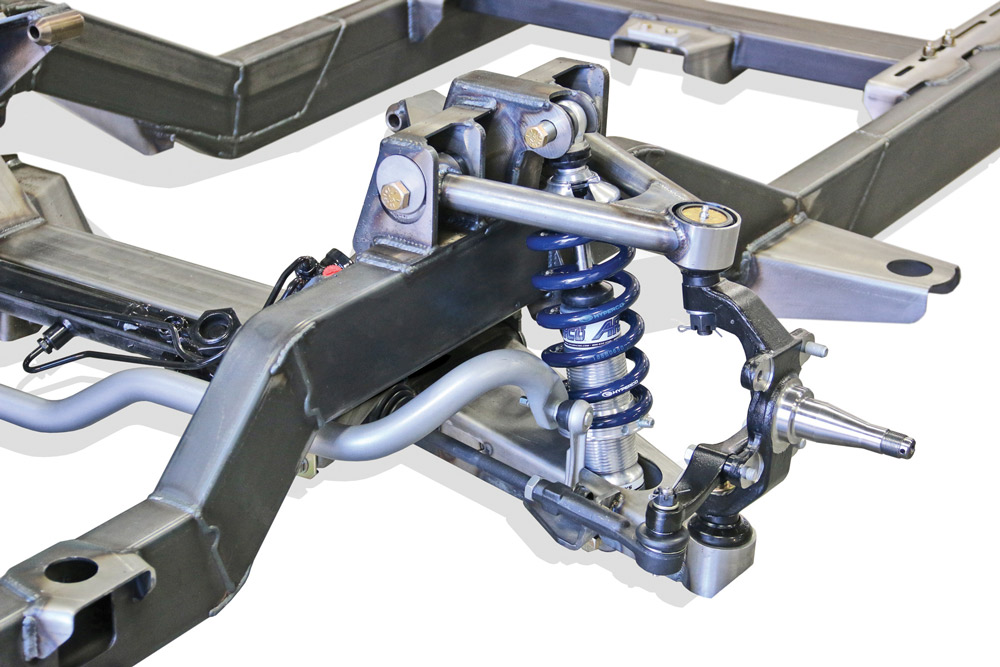

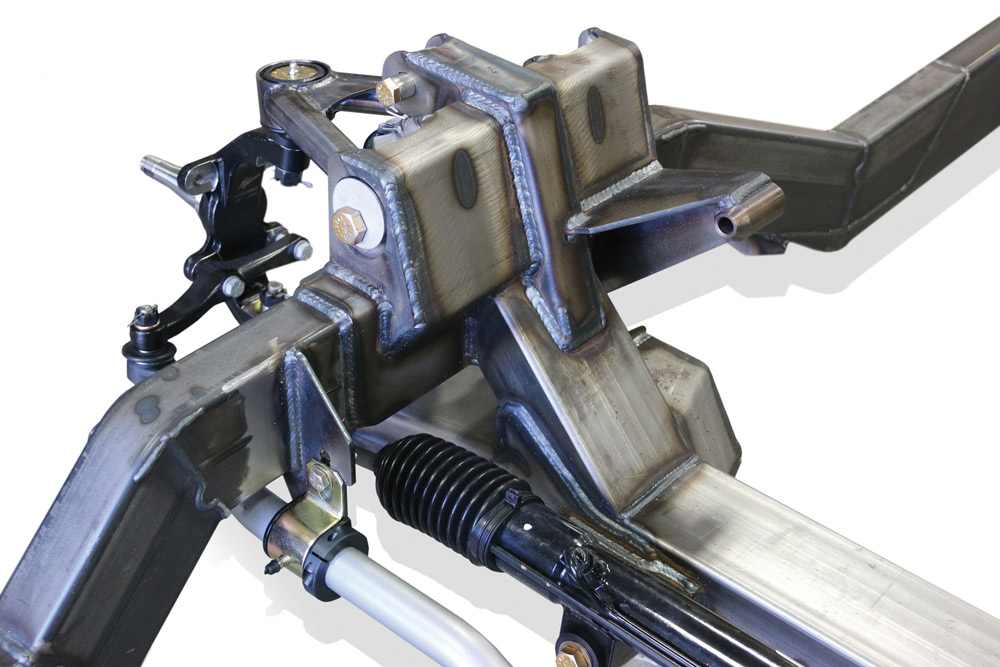

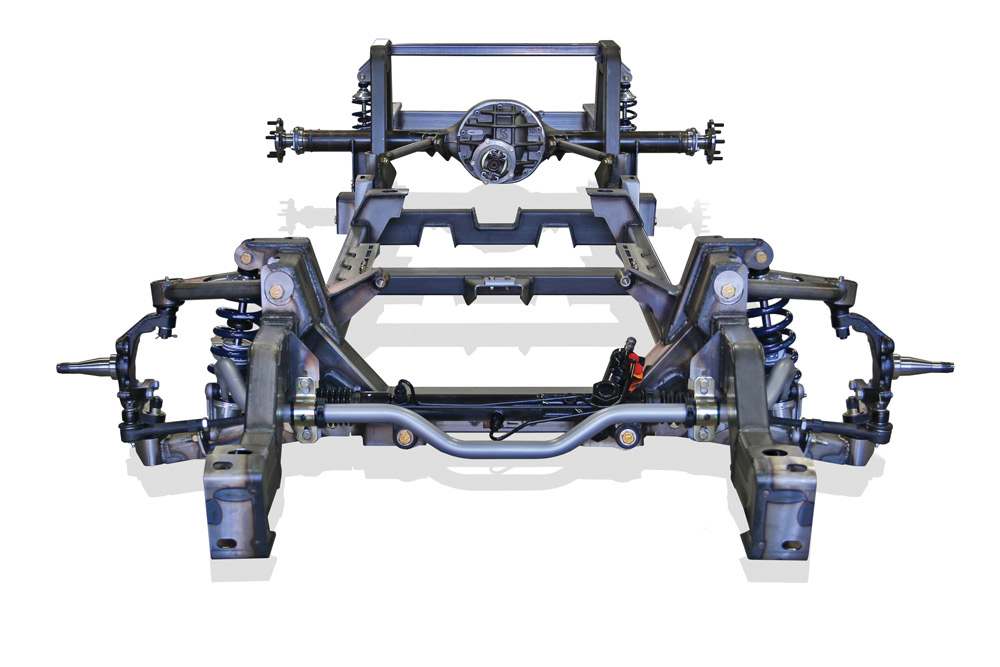

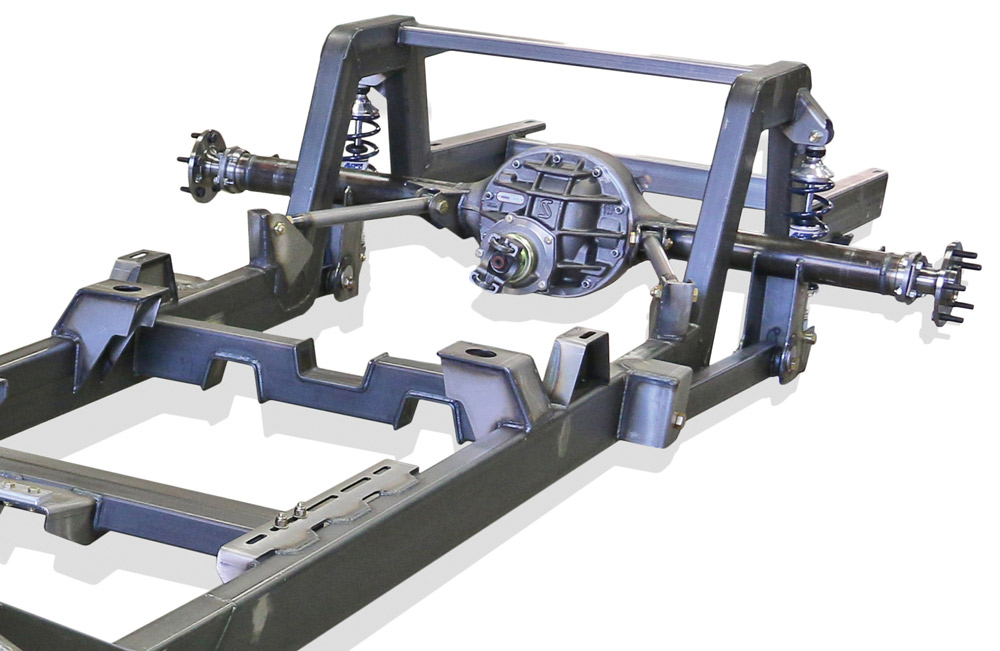

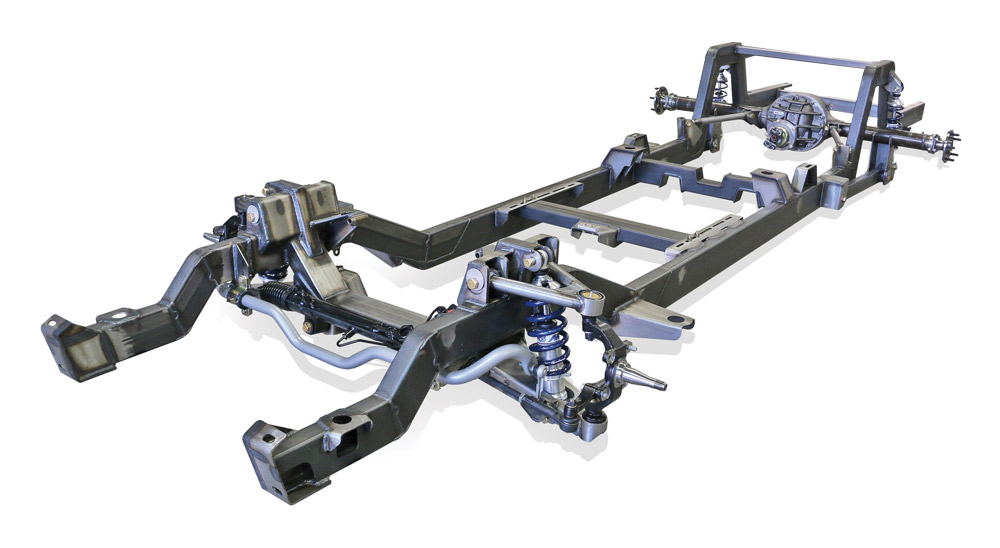

The chassis was designed to come together in less time, but also to perform on a track. To make this possible, the frame is formed by making specific cuts, bending it together and welding it solid. The front suspension consists of fabricated lower control arms and tubular upper control arms with eccentric mounts for easy alignment. Specialized Wilwood forged spindles are combined with rack-and-pinion steering to minimize effort during turning. The rear suspension is comprised of a triangulated 4-link with a 9-inch rearend. The frame is also equipped with all of the correct mounts so that the body can be bolted directly to it.

For all of these reasons and more, the Spec Series chassis is revolutionary. If you are planning to build a 1967-72 F-100 from the ground up, there is no reason to start your project with a tired old frame with obsolete components. This is especially true for a build that will showcase a high-performance engine and will be expected to hold down that power. Some of the optional components in pricing on these chassis are AFCO dual-adjustable coil-overs, 11-14-inch disc brakes, a front sway bar and rear end gearing. The chassis’ list of the advantages goes on. Continue reading to check them out yourself.

Share Link