BRANDON BURRELL

.

May 09, 2023

.

c10

BRANDON BURRELL

.

May 09, 2023

.

c10

When it comes to turning a build idea for an out-of-the- ordinary show vehicle into a show-stopping, finished product, there’s usually a struggle in finding the right shop to TURN your ideas into reality. Fortunately for Cameron Bishop from Phoenix, finding the right shop was easy. Cameron owns and operates Cuttingedge Hotrods and Fabrication, so getting the exact work done he needs isn’t a problem.

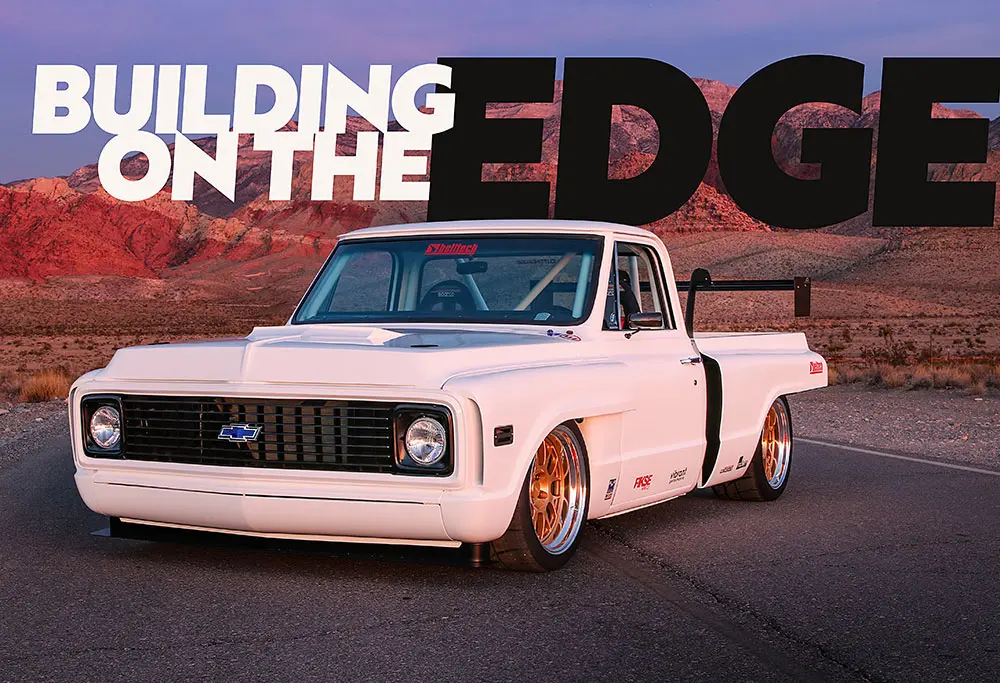

There have been close to a million C10 builds over the years, but Cameron wanted something different, something that fit a style that he’s always liked. Cameron always loved Group 5 special-production race cars of the ’70s and ’80s and wondered what a classic truck would look like if Group 5 had a truck class. He picked up a 1972 Chevrolet C10 and began brainstorming about what he could do to make the styles work together. As a fabricator, he knew it would take quite a bit of work, and he was ready for the challenge.

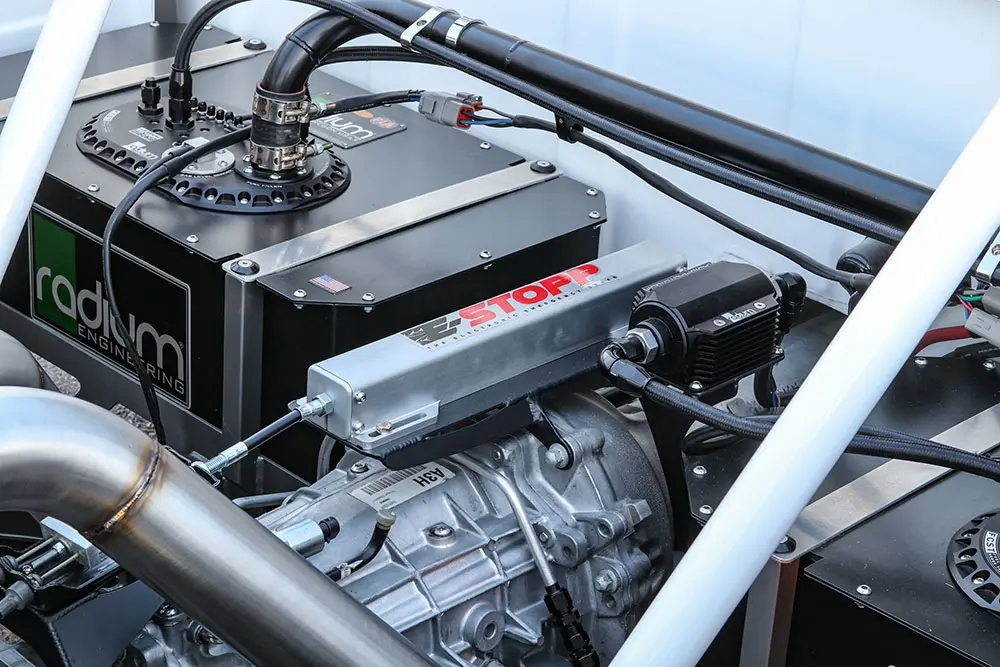

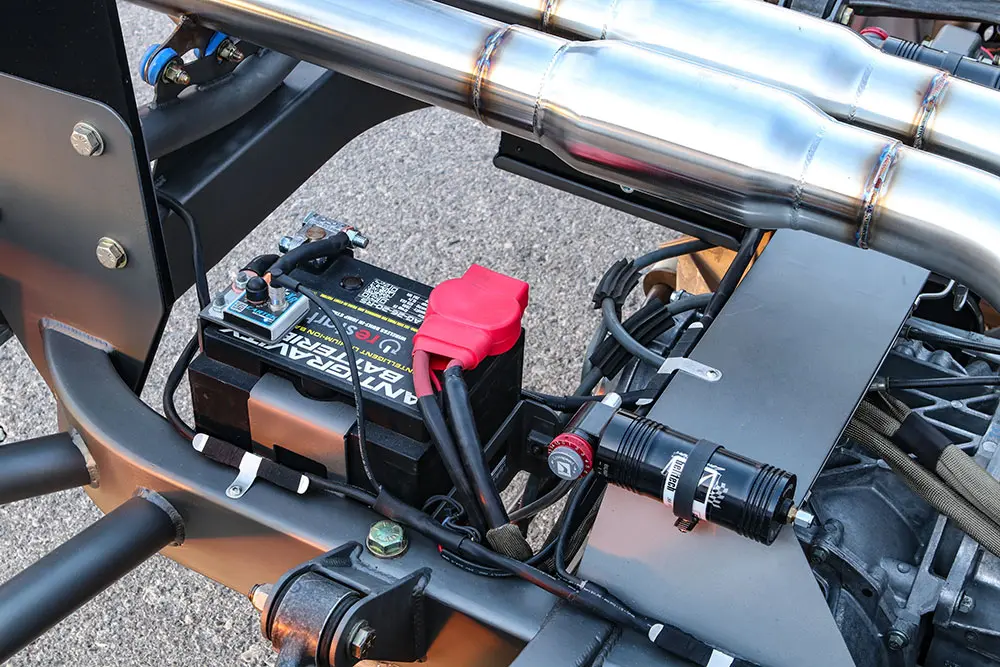

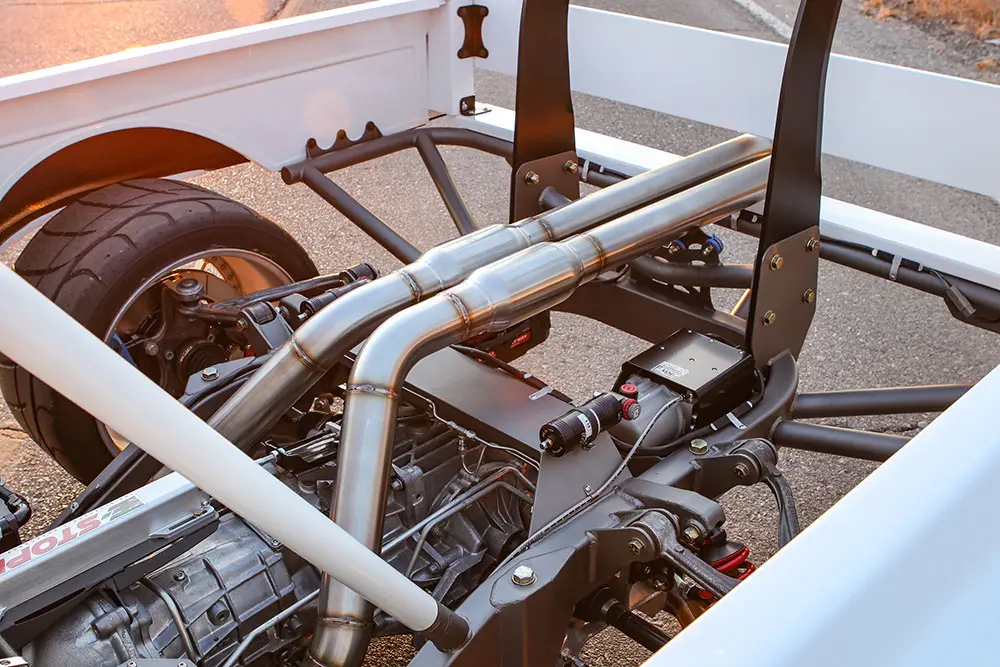

Getting the truck to sit like he wanted, Cameron designed and built his own chassis in-house using 2×4 mandrel-bent tubing with 0.188-inch-thick 4130 chromoly steel crossmembers. He designed the chassis to use C6 Corvette control arms, spindles, and rear-mounted transaxle. A set of KW Suspension-engineered Belltech V4 3A EXR triple adjustable coilovers on the front and rear keep the truck firmly planted in any curve Cameron throws it into. These coilovers also utilize KW’s HLS lift system to lift the front suspension 1.75 inches when commanded.

There have been close to a million C10 builds over the years, but Cameron wanted something different, something that fit a style that he’s always liked.

Once the chassis design was handled, he had to make sure he could get the Chevy’s dry sump LS3 to fit. To get the weight distribution he had in mind, Cameron pushed the engine back 14 inches, which put it 4 inches behind the front-wheel center line. By pushing the engine back, the truck now weighed 3,550 pounds at a 53/47 weight distribution.

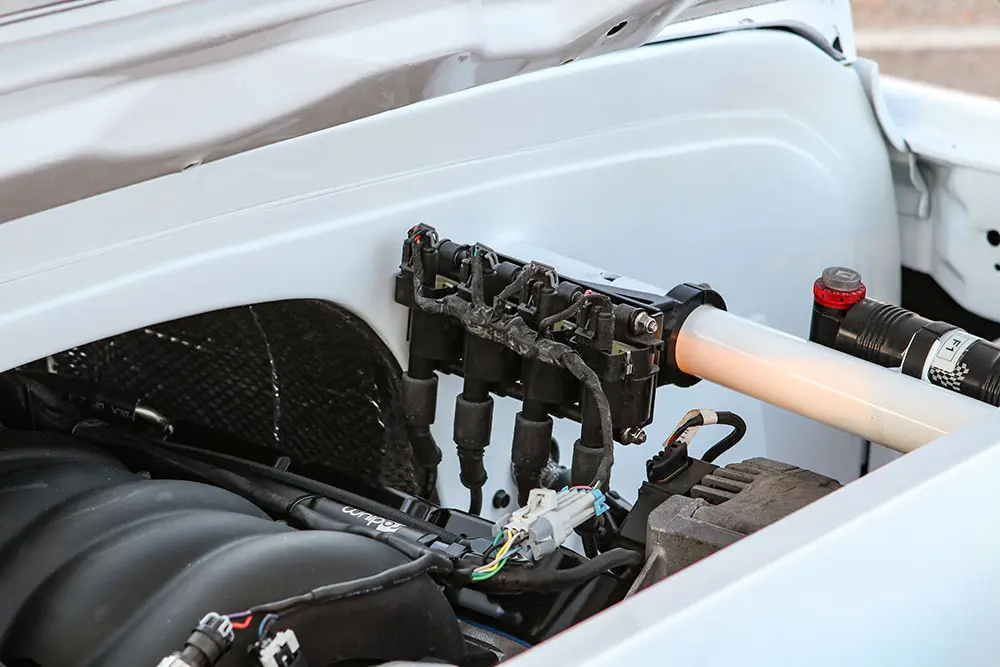

The chassis was set up to run two Radium Engineering fuel cells powered by the Racepak PDM with the fuel transfer logic controlled by the Holley Terminator X ECU. For internals, Cameron used a Tick Polluter Stage 3 camshaft, BTR dual springs, and retainers. The fuel is delivered through Radium Engineering’s fuel filter, fuel rails, and fuel pressure controlled by a Radium Engineering direct-mount fuel pressure regulator.

To keep this powerplant cool, a modified Ron Davis radiator was laid down using a custom fabricated aluminum core support. This combination allows the air exiting the radiator to be ducted directly up and out of the custom fabricated hood. Air is pulled into the engine by dual intakes that use the openings created by the wide-body front fenders to give them access to fresh air. Oil coolers were placed inside the openings created with the bedsides to keep engine oil and transmission fluid temps in check.

Getting the spent gases out of the engine required a bit more custom work than the intakes did. A call was made to Vibrant Performance for a truckload of stainless-steel U-bends and tubing. With that, a pair of one-off equal length stainless headers were created. Exhaust now flows through 3-inch collectors, X-pipe, and Vibrant Performance resonators. The exhaust then exits the back of the truck through the center of a fabricated tailgate.

The stopping the power this truck now puts down is thanks to a set of Wilwood 6-piston front brakes and 4-piston rear calipers. The Wilwood Tru-Bar pedal assembly with reverse mount Wilwood master cylinders make sure those massive brakes get the force needed. Covering those brakes is a set of 19×12-inch Fikse 801 three-piece wheels with minus-4 mm backspacing finished in Rothmans gold and wrapped in a set of 325/30-19 Nitto NT01 tires and placed on all four corners.

With the rolling chassis complete, it was time to get the body of this ’72 to fit the vision Cameron had for it. A ton of cutting and modifying was needed to get the exact look he desired. The bedsides and front fenders were cut apart, leaving the factory inner structure of these panels intact. This allowed for all OEM bolt locations and adjustments to remain the same as if they were still stock panels.

The sheetmetal was fabricated in-house a full 2 inches wider than factory. The wheelwell arches were cut and continue down the sides of the truck. The result was unique, one-off body parts that can still be adjusted and removed same as a factory truck. The hood was modified to accept the new radiator exit, and the cowl and wipers were shaved for a cleaner look. Once the metalwork was complete, the cab and parts were powdercoated inside and out and then sent to Dave Scotto at Deer Valley Autobody for the final bodywork and Sikkens white base and clearcoats for a clean and classy look. A carbon fiber chassis mount APR wing and new, old-stock Hella taillights for a Porsche 917 added a nice finishing touch to the look Cameron was after.

Because the truck had gone this far into the custom work realm and the engine now sat firmly where the factory dash once lived, there was no way Cameron could put a factory interior into it. It had to fit the theme he was working with and still be safe and effective whether for date night or on a racetrack.

Cameron built and TIG-welded a full 8-point roll cage out of 1.75 DOM tubing. He also fabricated an entire firewall and tunnel and modified the floor. The dash was hand-built out of aluminum and now holds a Holley 12-inch Pro-Dash touchscreen to monitor the truck’s stats. A restomod A/C unit was also added to keep the occupants cool on any of those track days or Arizona cruise nights. In case things ever get too “hot,” a SPA Technique fire suppression system was also added. A Sweet Manufacturing steering column and steering wheel disconnect were added to quickly remove the Sparco steering wheel when needed. Cartek wireless steering controls handle everything from starting the truck and lifting the front suspension to setting the electric parking brake. A set of blue Sparco Pro-2000 seats and Sparco belts were the final touch to this race inspired interior.

…it did come with its challenges like any other build. But as you can see, the outcome was well worth the effort.

It took Cameron about a year and a half to get the truck done and he debuted it in the Belltech/KW Suspension booth at the 2022 SEMA Show in Las Vegas. Owning and running the shop that built it made it a little easier than it would have been for someone not in his position, but fear not—it did come with its challenges like any other build. But as you can see, the outcome was well worth the effort. You can follow him at @cuttingedgehotrods on Instagram.

Owner

Cameron Bishop

Ride: 1972 Chevy C10

Hometown: Phoenix

Wheels/Tires

Chassis Modifications

Body Modifications

Paint

Interior

Engine/Performance

Special Thanks

Share Link