John Mata Jr.

.

November 11, 2022

.

Cover

John Mata Jr.

.

November 11, 2022

.

Cover

After some well-earned experience, Rob McPherson, director of business development at QA1, has some advice: “You can do everything yourself when building a truck and have some satisfaction when it’s done, or you can spend money somewhere to get it done faster,” he says.

A ’69 Camaro front subframe was brought in to not only lower the front of the truck but to also retain its suspension travel for optimum ride quality.

While Rob’s engineering background did help, he still had a lot to learn to take his ’56 Chevy truck across the finish line. TIG welding, aluminum fabrication, and bead rolling were all new things he had to familiarize himself with in order to accomplish as much as he did in his home garage.

Before Rob started on his Chevy truck, he had a vision of creating a pickup that he could hammer down at the track while still comfortably cruising during his much-needed downtime. With this project, he was looking to move out of his comfort zone by sinking his teeth into custom fabrication, which he has great taste for, as you will soon see. His fingerprints can be found everywhere on this truck, as he left very little for outside hands to do—an impressive feat given the quality of the results.

To kick things off, Rob started at ground level with the Chevy’s factory frame, which he chose to keep and modify. A ’69 Camaro front subframe was brought in to not only lower the front of the truck but to also retain its suspension travel for optimum ride quality. For the rear, Rob got to work on a 2×3 back half complete with a 4-link setup with Watt’s-link. He also fabricated a cross brace equipped with a transmission mount and driveshaft loop that would soon be utilized.

Since Rob had a pretty good “in” with QA1, he ran with its coilovers at each corner along with QA1’s Proma Star double adjustable shocks, which not only promote a better ride instantly but also offer an easy way to dial in ride height for the perfect stance. This is huge for those having a difficult time tracking down direct-fit shock options, which is especially handy for true custom applications like Rob’s ’56.

It’s obvious at this point that Rob was gunning for a performance pickup, so when it came time to choose a set of wheel and tires things started to get real interesting. Up front, a set of 17×8-inch Billet Specialties Street Lite wheels was selected for its clean, timeless appearance and weight-saving design. Out back, Rob ran with 15×14-inch Weld Racing ProStar wheels—one of the longest produced five-star style drag racing wheels out there! The heavily staggered front Falken and rear Mickey Thompson tires further solidifies the intentions set for this truck’s future on the track.

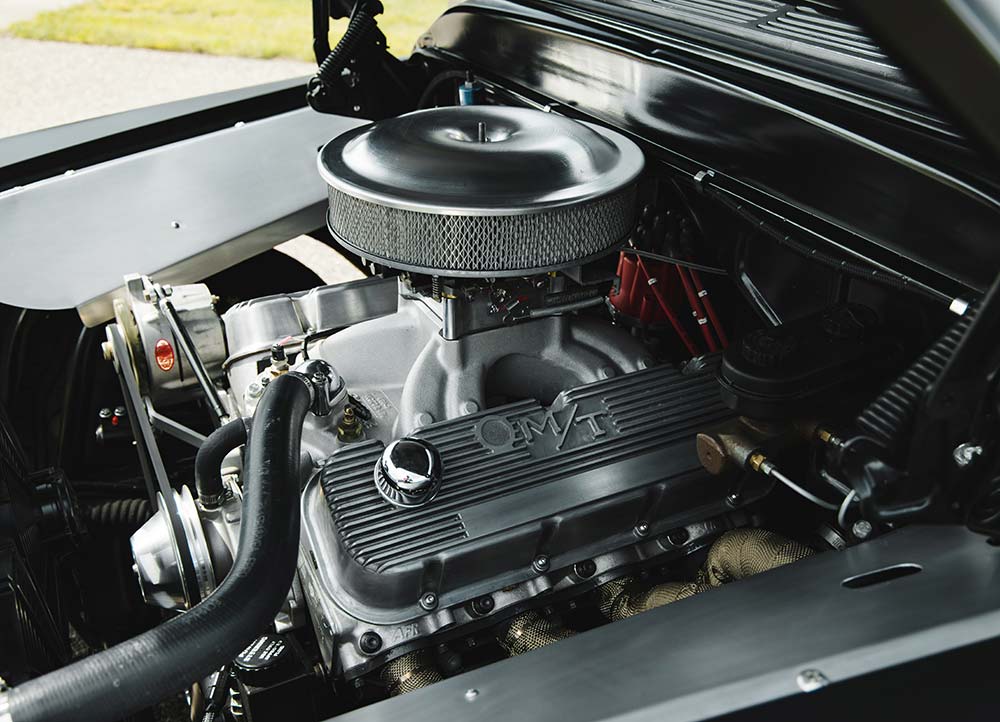

Rob recognized he’d need more than just wheels and tires to get the good times rolling. He soon started on building a ’72 Chevy 496 Big Block to squeeze between the frame rails. Since he was taking on the job in the comfort of his own garage, Rob really had the chance to geek out during this phase. Of course, he wanted respectable power (the truck currently dynos at 650hp with 675 lb-ft of torque), and to get just that, he dove into the abyss and came up with a winning combination of go-fast products that would deliver the big results he was after.

From an extensive list of top-shelf internals to visible and audible additions in the form of an Edelbrock intake, a custom 3-inch exhaust system, Cherry Bomb Salute mufflers and vintage Mickey Thompson valve covers just to name a few, the 496 was destined to be one rowdy source of power.

The only real outsourcing Rob did during the build of his ’56 is when the time came to secure a transmission. Extreme Automatic in Amelia, Ohio, found a ’97 GM 4L80 that would work perfectly. The trans was treated to a TCI Diablo shifter and an Extreme 9.5-inch custom torque converter. A QA1 3.2-inch carbon fiber driveshaft was then selected for its lightweight properties, as well as its sheer strength to the ground and delivery of quick acceleration.

When Rob began working on the Chevy’s body, he first set his sights on creating a custom bed floor that is comprised of custom wheel tubs and bead rolled panels (one of his newly acquired talents) with a bonus center access section that lifts up to help with regular maintenance and to show off Rob’s chassis work below. The front fenders were then flared ¾-inch and pie cut to maintain the original lip, and various firewall mods were made to accommodate the engine set back. After a few rust repairs, Rob then moved on to spray the black epoxy primer to the truck’s surface and apply custom QA1 decals to the doors.

The interior still needed some attention so Rob began by smoothing the dash, gutting the door panels and painting whatever needed a fresh coat of black primer to match the exterior. Fresh bare aluminum door panels and a trans cover were fabbed up, and for seating, a set of high-back buckets from JEGS were ordered, which might actually need some minor adjusting or replaced altogether. Standing at 6’3”, there isn’t much spare legroom for Rob as it is, so he just might have to make a set of lower profile seats (at least one for the driver side) to gain a few valuable inches to increase his comfort level dramatically.

While he was still in fabrication mode, Rob also put together a kickass, certified 8.50 8-point chromoly roll cage since he planned to put his Chevy through the paces on the 2021 Hot Rod Power Tour, which he has done successfully. Since it has been completed, the truck has made it out to numerous local shows as well as multiple QA1 #goDRIVEit cruises that are geared towards enjoying the beauty of taking the scenic route—how kick-back cruising always should be.

While Rob’s ’56 Chevy pickup project did take a good chunk of time to complete (about 7 years or so), he can honestly say that he designed and executed the majority of the work that went into the build. With that accomplishment comes a great deal of pride and a set of newly developed skills that will surely come in handy for the next project he takes on. For now, Rob plans on continuing what he’s been doing with the truck ever since he finished it—driving it fast and driving it often. His ‘56 is set up to perform and handle like a champ on the track as well as take it easy on twisty back roads. What else could anyone ask for?

Owner

Rob McPherson

1956 Chevy 3100 P/U

Eden Prairie, MN

Engine & Drivetrain

Chassis

Wheels, Tires & Brakes

Paint & Body

Interior

Share Link