Mike Self

.

November 17, 2023

.

Blood Sweat and Gears

Mike Self

.

November 17, 2023

.

Blood Sweat and Gears

LONG-TERM PROJECTS ARE A TWO-EDGED SWORD. They can be both relaxing and stressful, motivating and depressing, depending on what’s going right or wrong with the build and how much cash is left over to eat and pay the bills. More often than not, it’s a careful balance that leans slightly more toward pleasure than pain, so we put up with the lows in order to bask in the highs.

Chris Stafford knows these feelings all too well. As a member of Severed Ties, he was looking for his latest project when he came across a ’59 Chevy Apache.

“I’ve always liked the ’58-59 Chevy trucks, especially the big back window Fleetsides,” he says. “I had one before and traded it for my ’66 that I built, but I’ve always wanted another.”

When Chris picked up his ’59, he knew he’d have plenty of struggles with the project, but he was confident that the overall process—and the end product— would be worth it. As both a staff sergeant in the Army and the owner of Stafford’s Garage, Chris is already a busy dude, so the first obstacle he encountered was time, or a lack thereof.

Fortunately, Chris is no stranger to building trucks, so he’s been able to plan the project out to keep things as streamlined as possible, while still staying within somewhat of a budget. Of course, Chris somewhat jokingly admits that this budget has consisted of “…my life savings, and then some!”

The foundation of the Chevy is a completely custom frame fabbed up by Cody Stoute at Popeye’s Rod Shop, which uses a Long Shot Fabrication front suspension crossmember and custom mandrel-bent rails. The suspension uses Firestone 2600 air springs all around, with a parallel four-link and Watts link out back keeping the Speedway 9-inch rear end in check.

CPP got the nod for most of the front end components, such as the drop spindles and Mustang II steering rack, and the company’s disc brakes were mounted up all around. The air ride monitoring and adjustment is handled by an Air Lift 3H management system, with dual Flo Airride Mfg. air tanks and Viair 480C compressors providing the necessary pressure. Chris’ next move was to bolt on the 20×8.5 and 20×10 Raceline Desperado billets, which were stuffed into Toyo Proxes ST II tires, for a modern look.

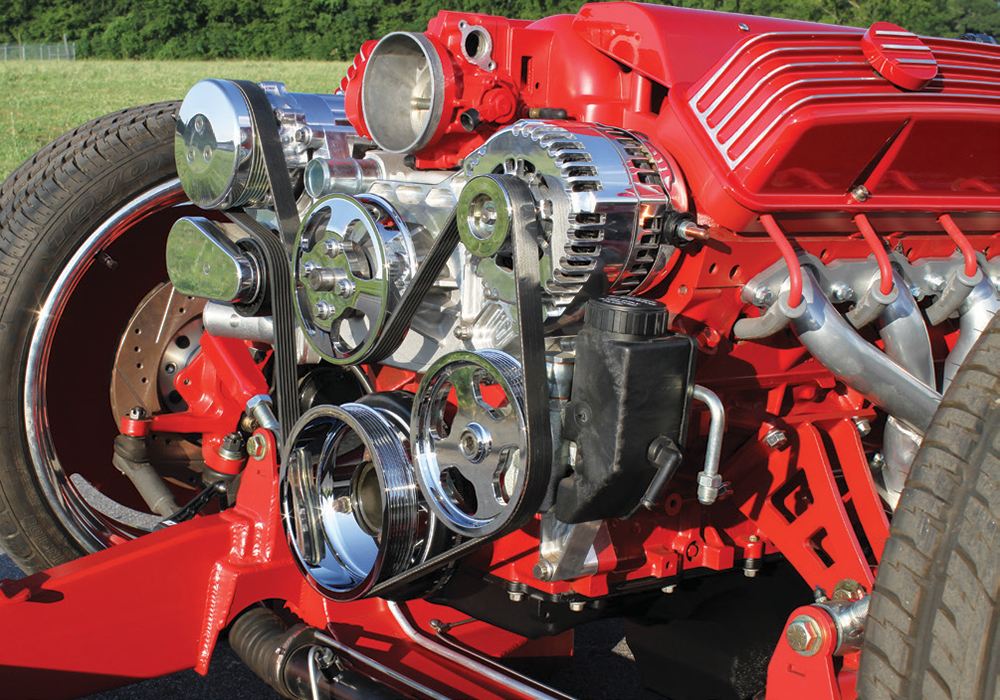

Power comes by way of a Gen III 6.0L LS, which was installed with the help of custom mounts by Popeye’s Rod Shop. The engine was upgraded with a smoothed Corvette intake manifold, ceramic-coated Sanderson headers and a custom 2.5-inch stainless Flowmaster HP2-based exhaust.

Chris also cleaned up the engine’s appearance with R-M Flame Red paint (which also covers the built 4L65E), a Vintage Air Front Runner accessory belt setup, All American Billet SBC valve cover adapters and fuel rail covers from Big Willie’s Garage. A custom aluminum fuel cell from Popeye’s takes care of providing the “go” juice for the ’59’s mighty LS.

On the other side of the firewall lies a leather-laden bench seat from Snowden Custom Seats done up by LB Upholstery and Dakota Digital HDX gauges give Chris the latest stats. Chris decided to keep the stock steering wheel, but opted to upgrade the column to one from Ididit, which was color-matched to the rest of the R-M Flame Red accents on the truck.

And although the body isn’t currently perfect by any means, it sports tucked bumpers, shaved stake pockets, a custom firewall, custom sheetmetal inside the bed with a Mar-K wood bed kit, and even a trick bed access door fabbed up by Popeye’s Rod Shop. Alan Kirkfield from Kirkfield’s Auto Body stripped the original finish off of the truck, then sprayed black R-M EP Series primer to hold Chris over until he gets around to painting it.

Chris is now two years into the project and has accomplished a lot in that amount of time. The plan is to have the truck completed for SEMA, which is just the excuse Chris was looking for to move things a bit more quickly this year. Mykals Custom Autobody is currently slaving away to get the truck bodywork completely wrapped up before SEMA. Nothing like the SEMA crunch to make miracles happen.

Share Link