Chris Hamilton

.

May 01, 2019

.

How to

Chris Hamilton

.

May 01, 2019

.

How to

If you’re picking up right where we left off in the March 2019 issue, you know that our goal with this project is to give new life to a slightly old daily driver you may already own. We started with a lifted 2WD Silverado on 35-inch tires. The truck looked nice and sounded great, but the ride quality was good at best, and it was lacking quite a bit of power. So, we decided to give this truck a complete makeover with sport truck styling and real performance to back it up.

In the last year we showed you how simply the front suspension can completely be replaced with coilovers and new spindles from Belltech. We also installed a new beefier sway bar that is included in their Sport Suspension kit. This new set up will bring our previously 7-inch lifted truck down to around 3.5 inches lower than factory stock height. A lower center of gravity and a dramatic drop in weight will finally allow us to feel the true benefits of this recently Procharged 5.3-liter V-8.

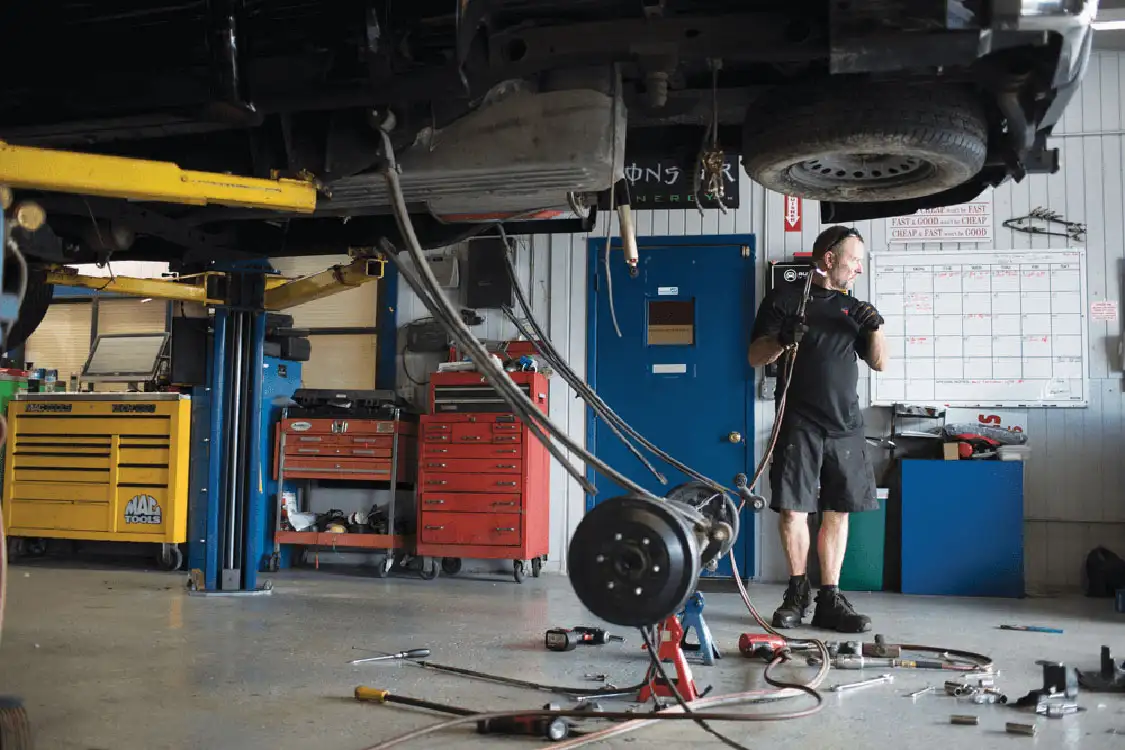

In this issue we are going to focus on the rear of our 2011 Chevy Silverado and explain just exactly how these flip kits work. Once we get it on the ground to adjust the coilovers and set the shock rates, we can pull it out of the bays, test the waters and see what we’re working with. Even though it looks great and it’s ready to go, the complete job is only halfway done. We will still need to replace the rear axle gears, re-tune the computer to adjust tire size and the air/fuel ratio, as well as a full alignment using Belltech parts. Keep following along in the future issues and give us your thoughts on the direction we’re headed. Now, back to the shop…

Share Link