Kevin Whipps

.

August 03, 2023

.

F100 Builders Guide

Kevin Whipps

.

August 03, 2023

.

F100 Builders Guide

It seems that a lot of stories that truck guys tell follow a similar narrative. They start out as a mini-trucker, building a ride or two along the way. Then they get married, maybe have kids, and when their priorities shift, they stop building for a bit. Once the kids are in school and the cash is flowing more smoothly, they get back up on the horse and start building again. All of that applies to Jonathan Mansour of Rowlett, Texas, with one big difference: television.

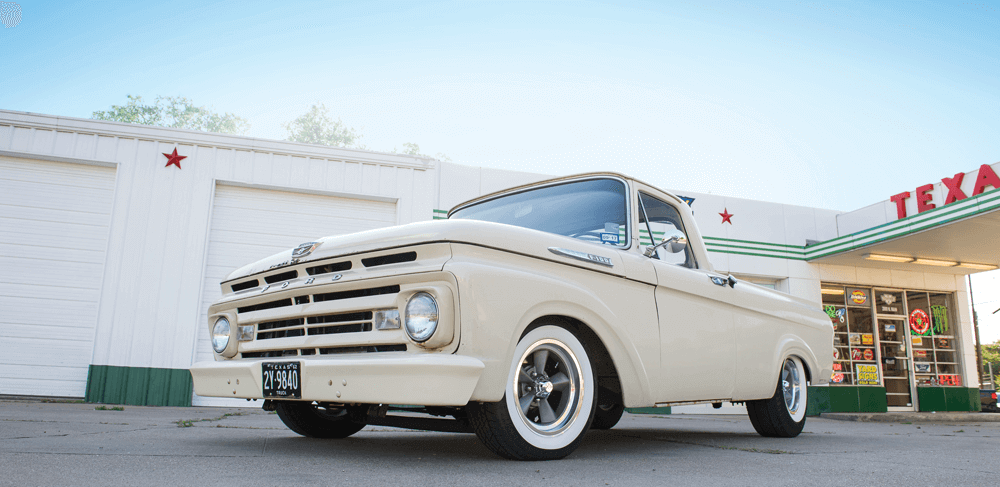

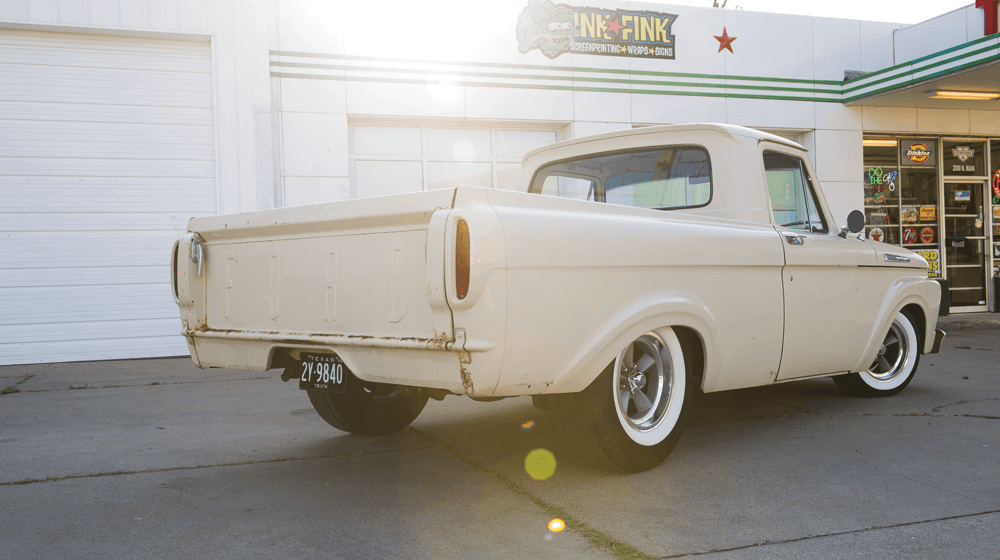

This article explores the restoration and customization of a 1962 Ford F-100 Unibody by Jonathan Mansour, in collaboration with Aaron Kaufman at Arclight Fab in Dallas, Texas. The build features a 302 V8 engine, custom suspension, and period-correct styling for an iconic truck transformation.

Who Is Jonathan Mansour and What’s His Connection to Arclight Fab?

It’s not often that a former mini-trucker finds himself on TV, but that’s exactly what happened to Jonathan. As an employee of Gas Monkey Garage and long-time friend of Aaron Kaufman, he found himself on “Fast ‘N Loud,” which would be a surreal experience for anyone. When circumstances shifted and Aaron opened up Arclight Fabrication, Jonathan went with him, bringing his expertise in marketing to the new venture. With a fresh slate and new opportunities, he wanted to build something that would bring him back into the scene and help out the shop. Fortunately, he already owned it.

Jonathan has always loved unibody Fords, but they can be difficult to find. He spent years combing Craigslist and other online listing sites trying to find the perfect specimen before the right one popped up. In an interesting twist, it was only 4 miles away from his home.

Once the kids are in school and the cash is flowing more smoothly, they get back up on the horse and start building again.”

What Makes the 1962 Ford F-100 Unibody So Special?

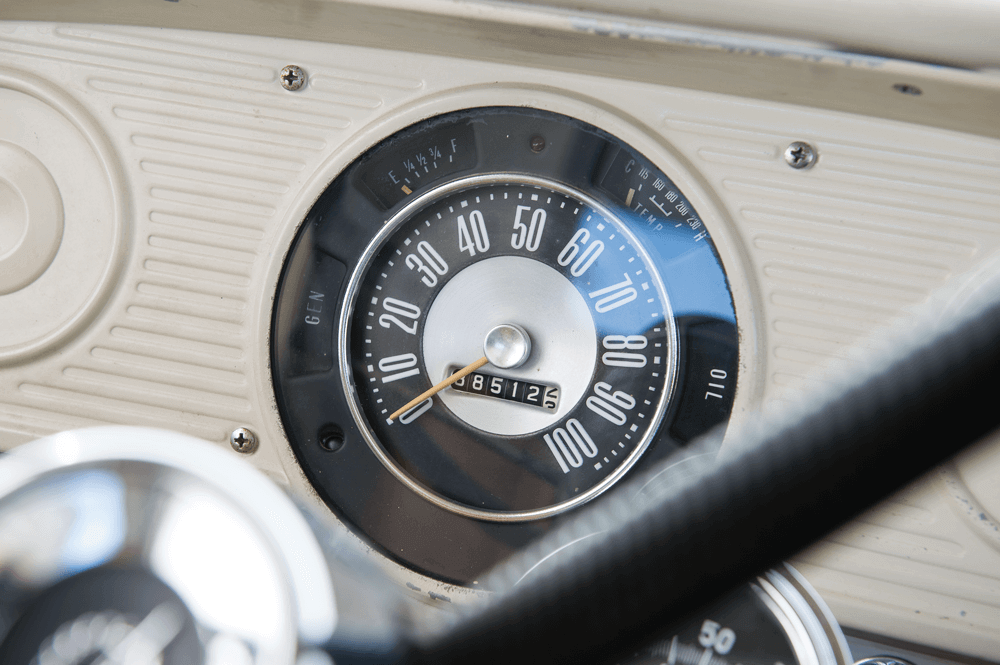

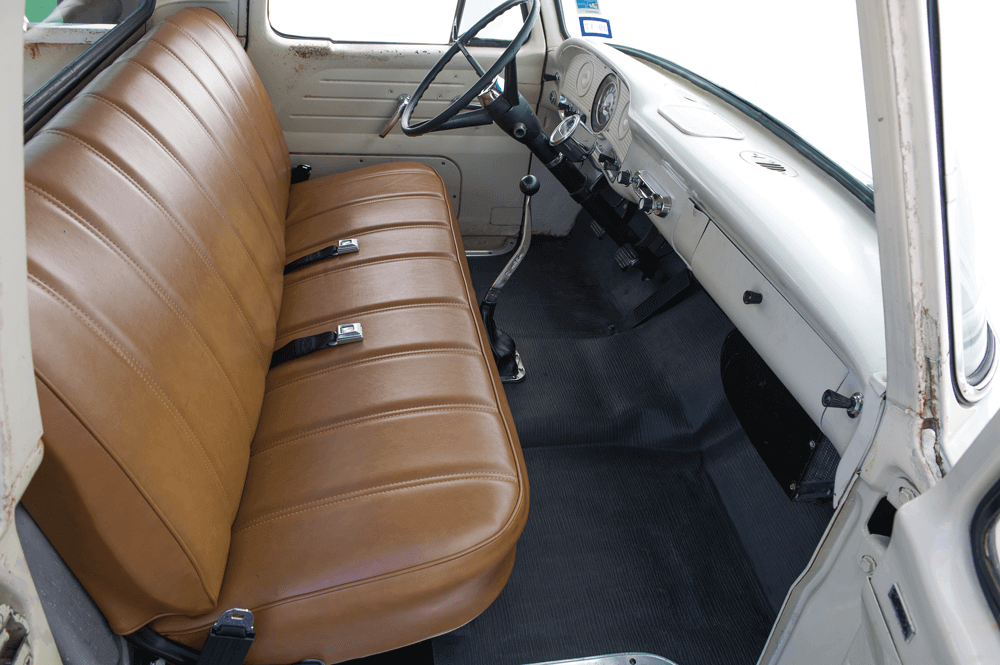

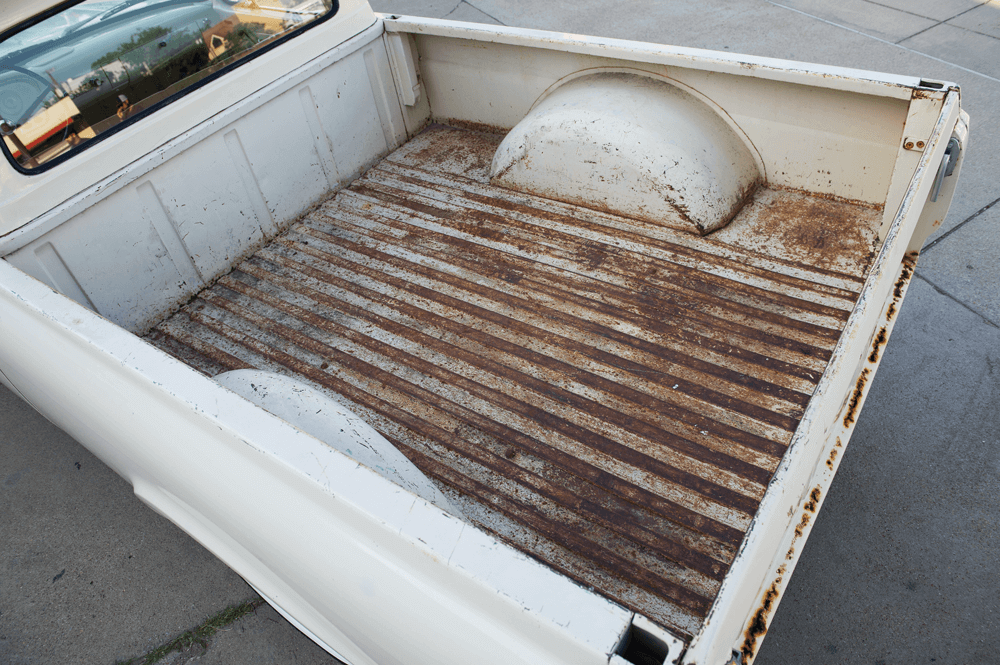

It was a 1962 Ford F-100 Unibody that had been purchased brand new off the lot and never touched. With the exception of a paint job in the ’80s to freshen up the finish, the truck was just driven and enjoyed for close to 40 years by the original owners, who then sold it to Jonathan. At the time, he was close to done with his ’98 Ford Ranger, and he wanted to move on to something else. But when the kids came, it was like a vacuum siphoned away his spending money, and the truck sat in his garage for around five years, never moving an inch.

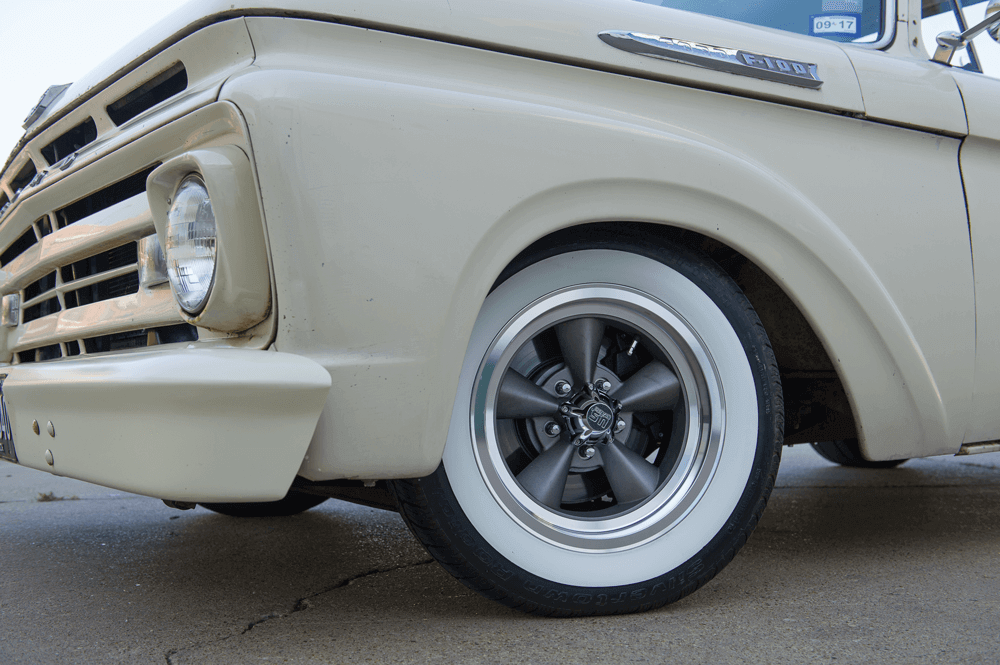

Eventually, Jonathan got tired of waiting, and he and Aaron started on Phase 1 of the build, which focused on getting the thing running relatively reliably, and bringing it down to the ground a bit. They installed a Nostalgia Sid’s drop axle paired with a mono-leaf. Aaron made a flip kit for the rear, and they left the drivetrain as-is. For 18 months that worked pretty well, but eventually the drum brakes and iffy motor became too much for Jonathan to deal with, so they decided to move on to Phase 2.

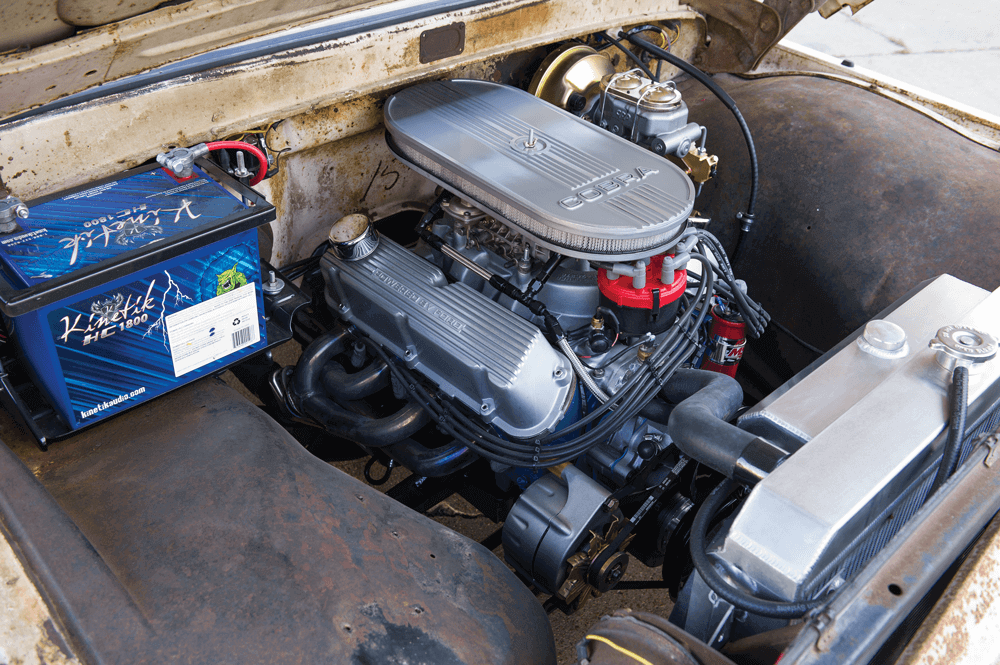

This time around it was all about power, both moving forward and stopping. The brakes were upgraded to disc with a CPP brake booster and master cylinder. Then the motor was swapped out for a Ford 302 that originally lived in Aaron’s Falcon and only had a few miles on it after its rebuild. Paired with a five-speed instead of the ancient three-on-the-tree manual, he had the ability to put the power to the pavement reliably and smoothly. It’s how the truck sits today, and it looks great.

Of course, there is a Phase 3 in the works. One of the plans over at Arclight is to build parts for 1957-79 Ford trucks, particularly a full chassis kit for each model. One of the first that they’re going to build will sit underneath Jonathan’s unibody, and even though it’s going to be tight, the plan is to get both his and Aaron’s trucks done for LST in 2018. It’s a lofty goal for a new shop, particularly one that’s now going to have its own TV show. But if there’s anybody that can do it, the team at Arclight Fabrication can certainly pull it off.

It seems that a lot of stories that truck guys tell follow a similar path, but they never end quite the same way. Jonathan and his ’62 have a bright future and some lofty goals to hit. If there’s one thing that’s sure, you can bet it’s going to be a fun ride.

OWNER

Jonathan Mansour

1962 Ford F-100

Rowlett, TX

Jonathan Mansour built a powerful 1962 Ford F-100 Unibody with help from Aaron Kaufman and Arclight Fab. It features a 302 V8 engine, modern suspension, and disc brakes. The build started in a garage and evolved into a professional-level custom truck with deep roots in Texas truck culture.

Special Thanks From the Owner: “I’d like to give a special thanks to my wife for the support and long hours during the build and for holding down the fort. The build wouldn’t have been possible without the help of my good friend, Aaron Kaufman. From parts around the shop from previous builds to the labor involved to make it happen, I couldn’t have done it without him.”

Early 1960s pickup trucks were primarily designed as utilitarian workhorses. These vehicles prioritized functionality over comfort, aiming to meet the demands of labor and transport. Their design reflected their primary role as tools for carrying heavy loads and enduring tough conditions.

In essence, the early 1960s pickup trucks were designed with a singular focus: to be reliable, hardworking vehicles capable of handling heavy-duty tasks with minimal concern for driver comfort or extended vehicle lifespan. Their primary purpose was utility, making them indispensable assets for industrial and agricultural work.

Pickup trucks have massively transformed over the past few decades. Initially designed purely as rugged workhorses, their role and design have shifted dramatically from the 1960s to 2020.

1960s:

2020:

1960s:

2020:

1960s:

2020:

In essence, today’s pickup trucks combine performance and luxury, offering features that were unimaginable in the 1960s. They have evolved from mere tools into multifunctional vehicles that cater to a wide array of needs and preferences.

Ford decided to adopt an integrated-body design for the 1961 F-100 primarily to streamline manufacturing and cut costs. By combining the bed and body into a single unit, they minimized the need for separate tooling and production steps associated with building multiple body panels.

This shift not only reduced manufacturing expenses but also allowed Ford to create a more spacious cargo area. The unified design provided a practical advantage in terms of increased cargo capacity, which was a significant selling point for customers relying on their trucks for heavy-duty tasks.

Additionally, this design distinguished the 1961 Ford F-100 from competitors by offering a unique structural integrity and durability, further enhancing its appeal in the marketplace.

In response to the challenges posed by the F-100’s unibody design, Ford took several significant actions. The unibody construction, despite its appealing aesthetics and urban utility, failed to meet the rigorous demands expected from a truck. Owners anticipated a vehicle capable of enduring hard labor, but the unibody design didn’t quite measure up.

Recognizing this mismatch, Ford pivoted swiftly. By mid-1962, they began producing conventional-bodied half-ton and 3/4-ton trucks. These new models, though hastily assembled, featured the box from the 1960 series, despite some misalignment with the 1961 body lines. This transition was crucial in addressing the durability concerns voiced by their customer base.

The unibody trucks continued production albeit with diminishing popularity. By the end of 1963, these trucks were sold alongside the conventional models. The market clearly preferred the traditional design, as evidenced by the conventional models outselling the unibody trucks two-to-one. This shift underscored Ford’s commitment to adapting their designs in response to customer feedback and practical utility requirements.

“It’s not often that a former mini-trucker finds himself on TV, but that’s exactly what happened to Jonathan. As an employee of Gas Monkey Garage and long-time friend of Aaron Kaufman, he found himself on ‘Fast ‘N Loud,’ which would be a surreal experience for anyone. When circumstances shifted and Aaron opened up Arclight Fabrication, Jonathan went with him, bringing his expertise in marketing to the new venture.”

Aaron Kaufman’s journey into the world of automotive fabrication and television is a testament to his passion and skill. From his early days working in a machine shop after high school, Aaron immersed himself in the art of metal fabrication, learning the ropes with minimal supervision. This hands-on experience laid the groundwork for his future ventures.

When television came calling, Aaron seized the opportunity to showcase his talents on a broader stage. His show, “Shifting Gears,” was a departure from traditional buy-sell formats, focusing instead on building vehicles for the sheer thrill of competition racing and creating memorable experiences. This innovative approach quickly gained traction, propelling the show’s popularity and allowing Aaron to build the cars of his dreams with ample budgets—albeit under the relentless pressure of TV deadlines.

Success came rapidly, marking a whirlwind period of building and racing, but after five action-packed years, Aaronchose to step away to pursue his own path. Reflecting on this chapter, he views it as an invaluable experience that packed a lifetime’s worth of car builds into a short span.

This blend of television exposure and deep-rooted fabrication expertise paved the way for Aaron’s next chapter, Arclight Fabrication—a venture that continues to push the boundaries of automotive creativity and innovation.

It’s not often that a former mini-trucker finds himself on TV, but that’s exactly what happened to Jonathan. As an employee of Gas Monkey Garage and long-time friend of Aaron Kaufman, he found himself on “Fast ‘N Loud,” which would be a surreal experience for anyone. When circumstances shifted and Aaron opened up Arclight Fabrication, Jonathan went with him, bringing his expertise in marketing to the new venture. With a fresh slate and new opportunities, he wanted to build something that would bring him back into the scene and help out the shop. Fortunately, he already owned it.

Aaron Kaufman’s journey in the television and automotive industry didn’t stop there. With the launch of his new show, “Shifting Gears,” Aaron shifted focus from the conventional buy-sell format to crafting vehicles meant for thrilling experiences. This new direction allowed him to explore the exhilarating world of competition racing, where the pressure to complete builds for events pushed his creative boundaries.

One such event is the renowned Pikes Peak International Hill Climb, also known as the Race to the Clouds. This race features a challenging 12.42-mile track with 156 turns and a climb of 4,720 feet, culminating at a breathtaking 14,115 feet above sea level. The 2022 event marked its 100th running, and Aaron was set to compete, showcasing his dedication and skill in such a prestigious race.

With each project and race, Aaron continues to cement his legacy in the automotive world, much like Jonathan aims to do with his marketing prowess at Arclight Fabrication. Their journeys intertwined, yet distinct, illustrate the dynamic nature of automotive innovation and the relentless pursuit of passion.

The fourth generation of the F-series trucks kicked off in 1961, marking the first significant redesign since 1953. This model introduced the “integrated-body” design, commonly referred to as the “unibody” truck. Unlike conventional trucks, the bed was not a separate part but merged into a single metal unit with the cab. This “unibody” construction increased cargo space and streamlined production costs by reducing the need for separate body panels.

Ford’s unibody design was specifically applied to the two-wheel-drive F-100 and F-250 Styleside pickups produced between 1961 and 1963. This particular choice made them distinct from the Flareside pickups, which retained a more traditional cab-and-bed structure due to their design requirements. By 1962, Ford began offering non-unitized Styleside pickups even for two-wheel-drive models, indicating a shift back to conventional designs.

However, the unibody design faced substantial issues. Stories began circulating about doors jamming when the truck was loaded and, worse, popping open when crossing rough terrain like railroad tracks. This body flex problem, exacerbated by rust over time, rendered the design unsuitable for heavy-duty tasks.

Due to these problems, 1962 saw Ford making swift changes. They started producing conventional-bodied half-ton and three-quarter-ton trucks mid-year. These new trucks utilized the box from the 1960 models, which didn’t align perfectly with the 1961 body lines but addressed the critical structural issues.

By 1963, Ford sold both the unibody and new conventional models side-by-side. The traditional body-on-frame models quickly became more popular, outselling the unibody versions by a margin of two-to-one. These conventional trucks retained the visual appeal but were more robust and practical, meeting the demands of users who needed a reliable work vehicle. Additionally, all four-wheel-drive trucks throughout this period maintained their traditional cab-and-bed structure, highlighting the unibody’s limited application and reinforcing the necessity for robust, separate body components in heavier-duty models.

No, all four-wheel-drive trucks maintained a traditional separate cab-and-bed structure.

Yes, by 1962, Ford began offering non-unibody options even for the two-wheel-drive Styleside pickups, indicating a shift away from the unibody design.

No, only the “Styleside” versions had a unibody design, while “Flareside” versions did not.

The F-100s and F-250s with two-wheel-drive were the models featuring a unibody design.

Despite its innovative design, the “unibody” F-100 faced significant issues. Owners reported problems with doors jamming when the truck was loaded and even popping open while crossing uneven terrain. This body flex was unacceptable for a utility vehicle, leading to a decline in its popularity. By mid-1962, Ford began producing conventional-bodied trucks again, eventually phasing out the “unibody” by the end of 1963.

However, the legacy of these trucks extends beyond their initial shortcomings. Today, unibody pickups have found a devoted following in the custom hot rod community. Their sleek, seamless appearance makes them ideal candidates for custom paint jobs and modifications, which often highlight their distinctive design. Though not suitable for heavy hauling or towing, these trucks possess an undeniable aesthetic charm that appeals to collectors and car enthusiasts alike.

The unibody’s story is a testament to the era’s bold automotive experimentation. While the design was ultimately flawed, it sparked innovative ideas that influenced future truck models. These trucks are now rare collector’s items, especially those that have been preserved without rust. Their presence at auto shows underscores their unique place in automotive history.

In summary, while the 1962 Ford F-100 Unibody owned by Jonathan has its charm and historical value, it also represents a bold but flawed chapter in truck design. This model’s story reflects both the innovation and the practical challenges faced by automotive engineers of the era. Despite its brief production run, the unibody design left a lasting impact, celebrated today for its visual appeal and historical significance.

These trucks were available from 1961 to 1963 and were part of Ford’s F-Series styleside pickups.

Ford’s unibody trucks are a design of the F-Series where the cab and bed form a single continuous piece, eliminating the gap typically found between them, although the chassis and body remain separate.

Ford decided to adopt an integrated-body design for the 1961 F-100 primarily to streamline manufacturing and cut costs. By combining the bed and body into a single unit, they minimized the need for separate tooling and production steps associated with building multiple body panels.

This shift not only reduced manufacturing expenses but also allowed Ford to create a more spacious cargo area. The unified design provided a practical advantage in terms of increased cargo capacity, which was a significant selling point for customers relying on their trucks for heavy-duty tasks.

Beyond manufacturing efficiency, Ford aimed to reach a different group of customers with this innovative design. They envisioned the unified styleside pickups appealing to a more suburban clientele, individuals who needed a vehicle that was both stylish and comfortable. The unibody design offered a clean, upscale appearance that set the F-100 apart from its competitors.

In terms of market differentiation, this design also introduced unique structural integrity and durability, enhancing its appeal. While the technology of the 1960s posed challenges, Ford’s leap towards a more integrated vehicle laid the groundwork for future models like the Chevy Avalanche and Honda Ridgeline, which successfully executed the unibody concept.

Furthermore, the cost factor played a pivotal role. Producing a truck as a single body piece rather than multiple components involved fewer stampings and simpler assembly processes. This not only reduced costs but also resulted in more usable storage space, aligning with the practical needs of truck users.

In conclusion, Ford’s decision to create a unibody pickup was a strategic move to blend cost-efficiency, aesthetic appeal, and functional benefits, targeting a specific market segment while paving the way for future innovations in truck design.

The unified body construction allowed for a more spacious and functional cargo area, enhancing the practical utility of the pickups.

The unibody design offered clean, seamless lines along the truck’s sides, which gave it a more upscale and appealing appearance.

Aaron describes his work experience as having achieved the equivalent of a lifetime’s worth of car builds within just five years, highlighting the intensity and richness of his journey.

Aaron views his participation in the automotive field as a tremendous blessing, indicating a deep sense of appreciation and fulfillment.

“Aaron Kaufman’s journey into the world of automotive fabrication and television is a testament to his passion and skill. From his early days working in a machine shop after high school, Aaron immersed himself in the art of metal fabrication, learning the ropes with minimal supervision. This hands-on experience laid the groundwork for his future ventures.

His interest in hotrods and fab work ran deep, almost as if it were ingrained in his DNA. This deep-seated passion made the decision to pursue a career in the industry an obvious and rewarding choice. Aaron’s natural inclination towards automotive craftsmanship and his eagerness to learn set him apart early on, enabling him to develop a robust understanding of the field.

The combination of his innate enthusiasm and practical experience propelled him forward, eventually leading to his successful ventures in both fabrication and television.”

He gained a comprehensive understanding of metal fabrication through practical, hands-on work, requiring minimal guidance as he developed his expertise.

After completing high school, Aaron embarked on his professional journey by working in a machine shop, where he began honing his skills.

His choice to pursue a career in the metal fabrication industry was straightforward, driven by his inherent interest and enthusiasm.

Aaron’s fascination with hotrods and fabrication is deeply ingrained in his background, indicating a long-standing passion for the industry.

“It’s not often that a former mini-trucker finds himself on TV, but that’s exactly what happened to Jonathan. As an employee of Gas Monkey Garage and long-time friend of Aaron Kaufman, he found himself on ‘Fast ‘N Loud,’ which would be a surreal experience for anyone. When circumstances shifted and Aaron opened up Arclight Fabrication, Jonathan went with him, bringing his expertise in marketing to the new venture.”

Before the roaring engines and high-octane drama of “Fast and Loud” became a household name, Aaron Kaufmanwas navigating a path filled with passion and ambition. His journey began with a meeting with Richard Rawlings, where they both envisioned the potential for success through thrilling automotive builds.

Their initial concept of a travel show never gained traction, leaving Aaron to continue his day-to-day routine. Yet, the allure of creating something extraordinary lingered. It wasn’t long before Richard returned with a bold new idea—one that would change everything. Two weeks later, with cameras rolling, “Fast and Loud” was born, propelling Aaron into the limelight and forever altering the course of his career.

Share Link