JACOB WHITE

.

October 24, 2018

.

Latest

.

JACOB WHITE

.

October 24, 2018

.

Latest

.

THE POPULARITY OF diesel-powered vehicles here in the U.S. has jumped dramatically in recent years. More and more manufacturers are offering new diesel power plants in ½-ton trucks, cars and midsize SUVs. Maybe the reasons for the boost are better highway fuel efficiency and the giant increase in torque offered by a diesel engine, but it’s probably an attempt to meet everincreasing CAFE (Corporate Average Fuel Economy) numbers. Either way, these smaller V-6 and four-cylinder engines will be sticking around. But back in the day, it was Cummins that developed its own small diesel engine market with the 3.9L 4BT.

Specification Detail

The 4BT—which stands for “fourcylinder B series turbocharged”— was used mostly in midsize box trucks, agricultural equipment and small industrial vehicles, and is basically a smaller version of the popular 5.9L 12V Cummins found in 1989-98 Dodge trucks. The 4BT shares virtually all of its parts with its big brother, the 6BT (e.g. pistons, connecting rods, injectors and valve-train design).

The major internal difference comes from the lack of two cylinders, which means two fewer journals on the crankshaft, a shorter camshaft, two fewer pistons in the injection pump, etc. But even these pieces are the same as the 6BT, just in an inline four-cylinder version. Because of these similarities, the 4BT Cummins has an extremely strong aftermarket, since many 5.9L 12V performance parts can be used in smaller 3.9L engines.

This, paired with the somewhat compact size of the 4BT, makes it a great candidate as a transplant engine for just about any vehicle. We’ve seen 4BTs in everything from Jeeps to old-school rat rods. The simplicity of the mechanical injection system also helps make it an easy swap because there’s little to no wiring or electronics required.

Since the engine was originally developed for industrial applications, big horsepower wasn’t a major concern, and the 239-cid motor most commonly came from the factory at around 105 hp at 2,300 rpm and 265 lb-ft of torque at 1,600 rpm. But these numbers could vary as much as 150 hp depending on the application.

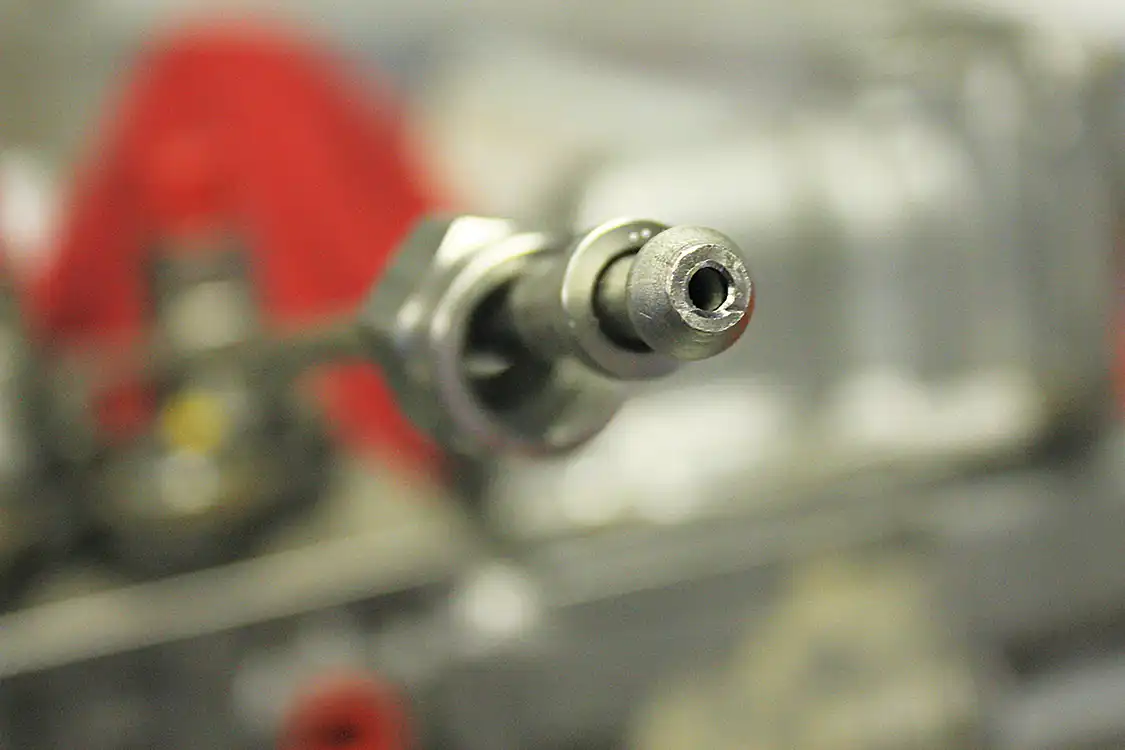

The 4BT engine weighs 750-780 pounds, which is heavier than most of the gas engines it would replace in a conversion project, but much lighter than the sixcylinder 6BT version. The inlinefour also offers a fairly compact size at just 30.6 inches long and 37.7 inches tall, which is useful with space constraints. The engines came with a few different injection pump systems, but the P7100 is, by far, the most popular, since it’s capable of producing larger amounts of fuel and more easily modified by the aftermarket to increase power outputs.

As previously mentioned, the 4BT can easily be modified to produce higher than stock power levels when outfitted with the P7100 (P-pump). Fueling mods can be taken to the same extremes as with the 5.9L 12V Cummins: 12mm and 13mm pumps with laser-cut delivery valves, high-rev governor springs, full-travel rack plugs and modified injectors can all be used in the 4BT platform.

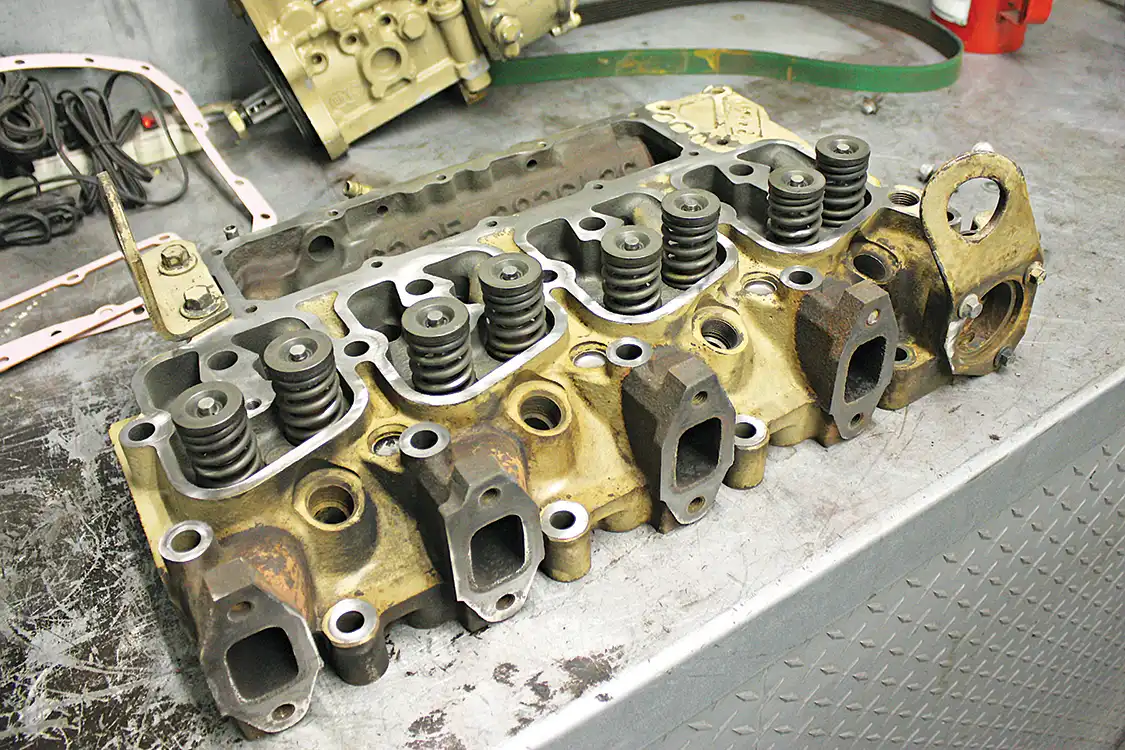

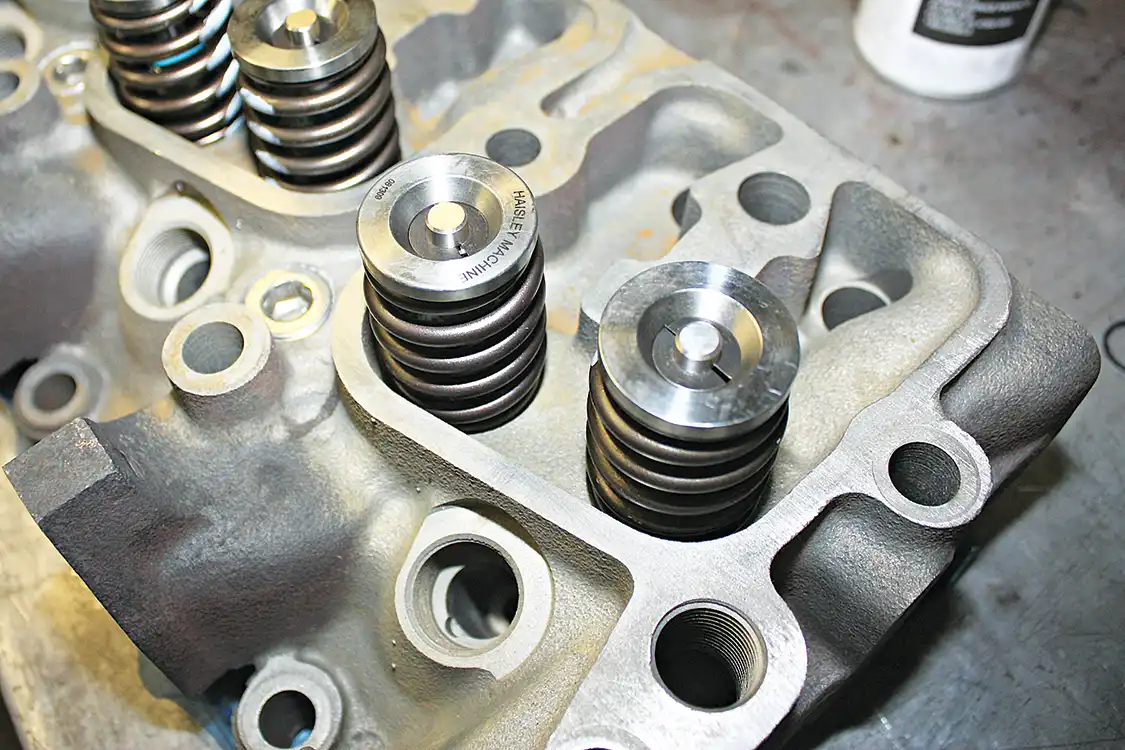

To go along with major fuel upgrades, common cylinder head and turbocharger upgrades are required, but the aftermarket already has most of that covered as well with head studs, better valve springs, larger valves and even performance exhaust manifolds and camshafts built for four-cylinder diesels.

While these upgrades can take the 4BT to all-new levels, we have to mention that because of its lack of cylinders and nearly identical operating rpm range, each piston is going to undergo a combustion cycle much sooner than that in a 6BT Cummins, so things like camshaft profiles and pump timing become critical for maximum efficiency at higher horsepower levels.

Like any engine platform, it’s a well-known fact that more cubic inches generally means more power, and there’s only so much a 239-cid motor can produce, at least safely and efficiently. With this in mind, ACD Engines of Salt Lake City has developed its Stroker Kit to take the 4BT to heretofore unheard of performance heights.

LIKE ANY ENGINE PLATFORM, IT’S A WELL-KNOWN FACT THAT MORE CUBIC INCHES GENERALLY MEANS MORE POWER, AND THERE’S ONLY SO MUCH A 239-CID MOTOR CAN PRODUCE, AT LEAST SAFELY AND EFFICIENTLY.”

Also known locally as “All Cummins Engines,” ACD has been a full-line Cummins dealer for more than 20 years, specializing in midrange and industrial engines. It offers virtually everything Cummins: new or remanufactured engines, new genuine Cummins parts, used engines and even salvage parts.

Since it deals in nothing but Cummins, ACD stocks many hard-to-find parts, and if it’s not in stock, the staff knows where to get what you need. Through their years of experience, the staff has become extremely wellversed in the 4BT platform and has the conversion process down to a science, inserting the small Cummins engine into Jeeps, small SUVs, pickups and even a mid- ’50s ambulance.

In the search for more power, owner Robby Pederson began development of a Stroker Kit that would increase the length of stroke and add some additional cubic inches to the inline-four diesel. In the gas world, Stroker engines are nothing new; the GM small-block 383 Stroker engines have been around for nearly 35 years. The 383 is built using a standard GM 350- cid engine block with a modified 400-cid crankshaft, which changes how far the piston travels.

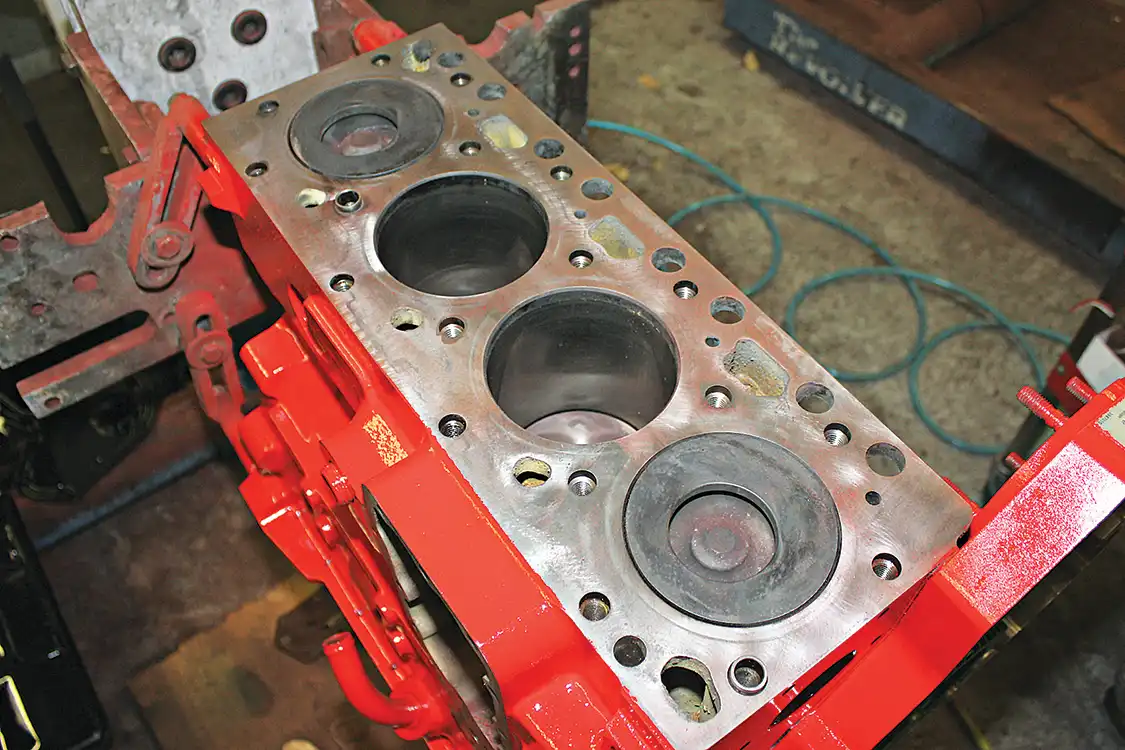

Because the factory 4BT crankshaft is a robust piece, Pederson didn’t want to do much crankshaft work, so he opted for an all-new piston and connecting rod design to gain the additional stroke he was after. A factory 4BT engine runs a 4.02-inch bore with a 4.72-inch stroke; this is how we come to a 239-ci motor. The new parts from ACD will allow the overall piston bore to expand to 4.402 inches with a much longer 5.430-inch stroke, effectively taking engine output to 333 ci, or 5.46L, almost that of the 5.9L 12V Cummins.

Knowing that the clientele for such a kit would be after extreme power levels, only the best materials were used to ensure the ACD Stroker Kit would stand up to high boost and high cylinder pressures. Rather than use standard-cast pistons, like the stock units, ACD went with a much stronger forged piston design that offers a different bowl design to improve the air/fuel swirl effect, helping create a more efficient burn in the combustion chamber.

The piston design also has a much shorter overall height, and the wrist pin location was moved closer to the deck. These modifications account for most of the additional stroke.

To match the new piston, connecting rods were developed and made from billet 4340, like those being used in all of the high-horsepower diesel engines. The new H-beam rod design is not only stronger than a factory connecting rod, but it also has a much smaller wrist pin journal, which will only work with the ACD piston. While the pistons and rods are the true heart of the Stroker Kit, ACD has also developed a host of 4BT parts to complement them and ensure true peak performance is achieved.

Specific camshaft profiles were designed, custom cylinder head work was done and 4BT-specific adjustable injection pump timing gears were installed. The short time between injection events on the four-cylinder engine required a slight engineering change for these parts, and ACD thinks its developed the perfect pieces to turn your run-of-the-mill 105-hp 4BT into a tire-shredding 800-hp monster.

ACD Engines understands that the complete Stroker Kit might be more than most 4BT project vehicles need, so it has an array of 4BT-specific products that can do everything from increasing power to improving fuel mileage and engine efficiency. It also carries a full line of custom brackets and conversion pieces to make your conversion or transplant project go a little easier.

• ACD Engines

877.506.8667

Acdengines.com

Read More: THE SMOGGLER A Diesel 4BT Powered F100!

Absolutely, there are various modern diesel engine options that might be superior choices compared to the 3.9L Cummins.

Modern diesel engines often come with advancements that offer:

In summary, while the 3.9L Cummins is reliable, newer diesel engines like the Duramax 3.0L, Power Stroke 3.2L, and EcoDiesel 3.0L come with significant benefits that make them worth considering.

Swapping to a 3.9L Cummins engine might seem enticing for those looking to improve fuel economy, but this consideration alone may not be sufficient to warrant the conversion. Here’s why:

The 3.9L Cummins engine is quite heavy, weighing about a third of a Jeep Wrangler. This added mass can negatively affect the vehicle’s handling and overall performance. Moreover, the increased weight places additional stress on the suspension and axles, potentially leading to more wear and tear, especially in smaller vehicles like Jeeps.

Both the 4BT and 4BTA variants are non-intercooled, turbo-diesel engines. While this eases installation by eliminating the need for intercooler ducting, enhancing performance will likely require you to add an intercooler. Fitting this component under the hood can be challenging and may require substantial modifications.

The potential fuel savings vary significantly based on the engine you are replacing. For instance, if your current vehicle averages around 15 miles per gallon, you might not see substantial savings since post-conversion fuel efficiency tends to range between 17 and 21 mpg. This marginal improvement may not justify the costs associated with the engine swap, making it harder to recoup your investment through fuel savings alone.

For heavier trucks and SUVs, the weight added by the 3.9L Cummins engine might not be as critical an issue compared to smaller 4x4s. Weight becomes a relative challenge in heavily modified off-road vehicles, where handling and stress distribution are more crucial.

While improving fuel economy is certainly appealing, it shouldn’t be your sole reason for swapping to a 3.9L Cummins engine. The added weight, potential handling issues, the need for additional components, and modest fuel savings make it essential to weigh all factors before committing to such a conversion. Consider looking at the complete picture, including how the weight and stress impact your specific vehicle type and your particular use case, before making this significant modification.

When swapping a 3.9L Cummins engine into a vehicle, fuel economy typically falls within a certain range. Real-world data suggests that you can expect between 17 and 21 miles per gallon (mpg).

However, these figures are influenced by various factors, including:

In essence, while the 3.9L Cummins engine offers a broad range of fuel efficiency, specific results will vary based on how and where you drive.

The 3.9L 4BT Cummins diesel engine has become an extremely popular platform for conversion projects throughout the past couple of years, and for good reason. Sharing virtually every internal and external piece with its big brother, the 5.9L 12V Cummins found in the 1989-98 Dodge Ram pickups, and coming as regular equipment in hundreds of commercial and industrial applications, parts availability, power potential, fuel mileage, and the lack of electronics make it an easy go-to engine when it’s time to squeeze a diesel platform into the frame rails of just about anything.

The major internal difference comes from the lack of two cylinders, which means two fewer journals on the crankshaft, a shorter camshaft, two fewer pistons in the injection pump, etc. But even these pieces are the same as the 6BT, just in an inline four-cylinder version. Because of these similarities, the 4BT Cummins has an extremely strong aftermarket, since many 5.9L 12V performance parts can be used in smaller 3.9L engines.

This, paired with the somewhat compact size of the 4BT, makes it a great candidate as a transplant engine for just about any vehicle. We’ve seen 4BTs in everything from Jeeps to old-school rat rods. The simplicity of the mechanical injection system also helps make it an easy swap because there’s little to no wiring or electronics required.

When it comes to engine swaps, the 3.9L Cummins is definitely worth bringing to the table. If you have a full-size application, such as trucks or larger SUVs, the 4BT isn’t a bad option. It’s particularly appealing if you’re looking to build a reliable overland-type rig that can handle long-distance travel and rough terrain.

For more compact and nimble vehicles, like the Jeep Wrangler, the 3.9L Cummins might not be the best option. The weight and size of the engine could affect the vehicle’s handling and performance. There are better-suited engine options for these kinds of vehicles, which are designed to maintain their agility and off-road capabilities.

In summary, the 3.9L 4BT Cummins diesel engine offers a versatile and robust option for a variety of vehicle conversions but shines brightest in full-size vehicles where its power and simplicity can be fully utilized. Whether you’re working on an overland rig or a custom build, understanding the suitable applications for this engine can help you make the best choice for your project.

The 4BT can easily be modified to produce higher than stock power levels when outfitted with the P7100 (P-pump). Fueling mods can be taken to the same extremes as with the 5.9L 12V Cummins: 12mm and 13mm pumps with laser-cut delivery valves, high-rev governor springs, full-travel rack plugs, and modified injectors can all be used in the 4BT platform.

To go along with major fuel upgrades, common cylinder head and turbocharger upgrades are required, but the aftermarket already has most of that covered as well with head studs, better valve springs, larger valves, and even performance exhaust manifolds and camshafts built for four-cylinder diesels.

While these upgrades can take the 4BT to all-new levels, we have to mention that because of its lack of cylinders and nearly identical operating rpm range, each piston is going to undergo a combustion cycle much sooner than that in a 6BT Cummins, so things like camshaft profiles and pump timing become critical for maximum efficiency at higher horsepower levels.

However, it’s important to note that the 4BT is not a modern diesel. In fact, it’s a bit antiquated and unrefined. For some, the rattle, shake, and noise of this diesel will be too much. These characteristics can be a significant drawback if you’re looking for a smoother, quieter ride.

Additionally, you can’t simply hook a programmer to a 4BT and voila—you have 500hp. Yes, you can turn up the power, but it’s going to take real work and a serious investment of funds to get the numbers into the bragging realm. This means that while the 4BT has a lot of potential, prospective modifiers should be prepared for the commitment in both time and money.

By understanding these limitations and the extent of modifications necessary, you can better assess whether the 4BT is the right platform for your performance goals.

The 4BT engine weighs 750-780 pounds, which is heavier than most of the gas engines it would replace in a conversion project, but much lighter than the six-cylinder 6BT version. The inline-four also offers a fairly compact size at just 30.6 inches long and 37.7 inches tall, which is useful with space constraints.

However, this added weight can put more strain on the vehicle’s suspension and axles. For full-size trucks or SUVs, the weight won’t be as much of an issue due to their robust build. Weight is often relative when it comes to heavily modified 4x4s, meaning the impact can vary significantly based on the level of modification.

This nuanced understanding helps in making informed decisions when considering a 4BT engine conversion, ensuring vehicle handling and suspension are adequately addressed.

The 3.9L 4BT Cummins diesel engine has become an extremely popular platform for conversion projects throughout the past couple of years, and for good reason. Sharing virtually every internal and external piece with its big brother, the 5.9L 12V Cummins found in the 1989-98 Dodge Ram pickups, and coming as regular equipment in hundreds of commercial and industrial applications, parts availability, power potential, fuel mileage and the lack of electronics make it an easy go-to engine when it’s time to squeeze a diesel platform into the frame rails of just about anything.

Why the 3.9L Cummins is a Top Choice for Swaps

These figures show that despite its relatively compact size, the 3.9L Cummins packs a punch, making it perfect for a variety of conversion projects.

First hitting the market in 1983, the 3.9L Cummins, also known as the 4BT, has been utilized in everything from delivery trucks to wood chippers. This widespread use means the engines are not only easy to find but also affordable. Their robust design and mass availability make them a practical choice for enthusiasts looking for reliability without breaking the bank.

One of the standout features of the 3.9L Cummins is its minimal reliance on electronics. This simplicity significantly eases the conversion process, allowing for a smoother integration into various projects. Whether you’re dealing with an older vehicle or a custom build, fewer electronics mean fewer complications.

The engine’s compatibility with a slew of manual and automatic transmission options adds another layer of versatility. It allows for a wide range of applications, catering to different needs and preferences.

Sharing much of its DNA with the revered 5.9L 12-valve Cummins, the 3.9L offers a similar promise of durability and reliability. This connection gives diesel enthusiasts confidence that the engine can withstand the test of time and usage.

In conclusion, while there might be other diesel options out there, few can match the 3.9L Cummins in terms of cost-effectiveness, ease of conversion, and overall reliability. It’s no wonder this engine remains a favorite among those looking to undertake conversion projects.

Overall, the 3.9L Cummins diesel engine stands out for its mass availability, simplicity, and versatility. However, it is important to weigh these advantages against its drawbacks, particularly the added weight and lack of modern refinements. If you’re considering an engine swap, the 3.9L Cummins offers a robust and reliable option, especially for full-size applications. For smaller, more nimble vehicles, you may want to explore other alternatives.

The Cummins 4BT engine, though praised for its durability, comes with a set of issues and reliability concerns that potential users should be aware of.

One of the primary challenges with the 4BT engine is its physical size. It’s a bulky and heavy engine, making installation in smaller vehicles quite difficult. The engine’s significant weight can strain the front suspension of smaller 4×4 vehicles, leading to handling issues and potentially increased wear and tear on the suspension components.

The 4BT is notorious for being loud and shaky. This characteristic is typical of older diesel engines and can be quite uncomfortable for those accustomed to more modern, quieter engines. The noise and vibration can also be a concern for long-term use, potentially leading to cabin discomfort and increased fatigue during extended drives.

Another common issue is the level of emissions produced by the 4BT engine. Being an older diesel engine, it tends to release more smoke compared to newer models. This can be a significant drawback in terms of environmental impact and may not meet modern emissions standards without additional modifications.

While the 4BT is robust, it doesn’t always provide enough power for larger vehicles, such as full-size trucks or SUVs. Users looking to install this engine in such vehicles may find its performance lacking, particularly in demanding driving conditions.

The installation process can be quite complex due to the engine’s need for additional components like an intercooler and associated piping. This not only makes the installation more labor-intensive but can also increase the overall cost.

In summary, while the Cummins 4BT engine is known for its simplicity and ease of repair, potential users should consider its size, noise levels, emissions, and power limitations. Ensuring proper installation and accommodating for its physical and mechanical characteristics can help mitigate some of these concerns, but it’s crucial to weigh these factors against the engine’s benefits before making a decision.

Installing a Cummins 4BT engine in a small vehicle comes with several significant challenges:

Overall, these factors make the installation of a Cummins 4BT engine in a small vehicle a complex and often impractical endeavor.

The Cummins 4BT engine is a versatile powerhouse with several variations, each designed to optimize performance for specific applications. Here are the primary versions:

In addition to these core versions, automotive charge air-cooled engines from Cummins have varied designations depending on the specific model and production year. This ensures that there is a 4BT variant tailored to nearly every conceivable use-case scenario, from industrial machinery to on-road vehicles.

Understanding these different versions helps in selecting the right 4BT engine to meet your specific requirements, whether for enhanced power, durability, or specialized applications.

The Cummins 4BT engine features durable construction materials that contribute to its robust performance. The engine block is made from cast iron, ensuring strong structural integrity. Additionally, the cylinder head is also constructed from cast iron, providing reliability and longevity under high stress and temperature conditions.

These cast iron components are essential for the engine’s durability, allowing it to withstand the rigorous demands often placed on commercial and industrial engines.

The 4BT engine uses a simple two-valve-per-cylinder system, one for intake and one for exhaust. While this design became somewhat outdated with the introduction of the four-valve-per-cylinder design found in the 1998.5-plus 6BT engines, it’s still a sufficient and robust design, especially on the smaller cubic inch, low 130-180-hp applications for which most of the 4BT engines were designed.

To understand how the valvetrain operates, it’s important to note that the engine features an OHV (Overhead Valve) system. The camshaft is mounted into the block and is driven by the crankshaft through gears located at the front end of the engine, which also drive the oil pump. This camshaft plays a critical role: it opens and closes the valves by pushing through rocker arms via pushrods and solid tappets.

Despite its simpler two-valve-per-cylinder design, the 4BT engine’s valvetrain remains effective for its intended applications. The camshaft’s precise interaction with the pushrods and rocker arms ensures reliable valve operation, contributing to the engine’s overall durability and performance in specific, lower horsepower uses.

The Cummins 4BT and 4BTA3.9L engines are powered by diesel fuel. These engines are renowned for their reliability and efficiency, making diesel the ideal choice for various applications. Diesel not only provides the necessary power and torque for demanding tasks but also ensures optimal performance and fuel economy. Whether used in industrial settings, off-road vehicles, or marine applications, the combination of diesel fuel with these engines delivers durability and consistent power output.

If you’re working with the Cummins 4BT and 4BTA3.9L engines, it’s crucial to set the valve lash correctly to ensure optimal engine performance and longevity. Below are the specifications you’ll need for both the intake and exhaust valves:

Proper valve lash settings are essential for several reasons:

Following these specifications will help maintain your engine’s health and performance, ensuring that your vehicle operates smoothly and efficiently.

When dealing with the Cummins 4BT and 4BTA3.9L engines, a critical detail to ensure their smooth operation is understanding their firing order. Both of these engine models follow the same firing sequence, which is essential for optimal performance and engine longevity.

This sequence ensures that the power delivery is balanced and that engine vibrations are minimized, enhancing overall efficiency.

Whether you’re rebuilding an engine, performing routine maintenance, or diagnosing engine issues, knowing this firing order can make a significant difference in the outcome and reliability of your engine work.

The factory 4BT engine runs a 4.02-inch bore with a 4.72-inch stroke; this is how we come to a 239-ci motor. However, for those curious about the precise measurements of the Cummins 4BT and 4BTA3.9L engines, you might find it interesting to know that they boast a bore of 4.0165 inches and a stroke of 4.724 inches.

The new parts from ACD will allow the overall piston bore to expand to 4.402 inches with a much longer 5.430-inch stroke, effectively taking engine output to 333 ci, or 5.46L, almost that of the 5.9L 12V Cummins.

This expanded capability illustrates the potential for performance upgrades while maintaining the robust foundation of the original engine specifications. Understanding these measurements not only helps in appreciating the stock engine’s capabilities but also in considering the possibilities for future enhancements.

Overall, the 3.9L Cummins diesel engine stands out for its mass availability, simplicity, and versatility. However, it is important to weigh these advantages against its drawbacks, particularly the added weight and lack of modern refinements. If you’re considering an engine swap, the 3.9L Cummins offers a robust and reliable option, especially for full-size applications. For smaller, more nimble vehicles, you may want to explore other alternatives.

The 4BT Cummins, known for its impressive fuel efficiency, achieves this through its high compression ratio and efficient turbocharged design. Built for low-RPM, high-torque performance, it delivers power efficiently without burning excessive fuel. Many users report achieving up to 40 miles per gallon with properly tuned 4BT setups, particularly in lighter vehicles.

This level of fuel efficiency makes the 4BT an attractive choice for those looking to optimize for economy without sacrificing performance. As you assess your options for engine swaps, the potential fuel savings with the 4BT Cummins might be a compelling factor to consider, especially if mileage is a priority in your decision-making process.

It is optimized for delivering high torque at low RPMs, enabling it to generate power without excessive fuel consumption.

The engine’s remarkable fuel efficiency is largely due to its high compression ratio and the presence of an efficient turbocharger.

The engine is designed to perform optimally at low RPMs while delivering high torque. This allows the 4BT Cummins to generate necessary power efficiently, minimizing fuel usage.

The engine is praised for delivering consistent torque and impressive fuel economy, making it an ideal option for those seeking a balance of power and cost-effectiveness in their vehicle builds.

Its combination of durability and efficiency makes it suitable for various vehicle types, including pickups, SUVs, and specialized off-road rigs. This versatility provides users with both the power and practicality they need.

The engine’s compact design allows it to fit into vehicles with tight engine bays, making it an excellent choice for custom builds. Its ruggedness and adaptability mean it can enhance both the performance and capability of a wide range of vehicles.

The 4BT Cummins demonstrates exceptional performance in a variety of settings, from daily driving to off-road adventures. Its reliable power and versatility make it well-suited for handling diverse conditions and tasks.

Compound turbocharging is a game-changer for the 4BT Cummins engine, particularly in the quest for high horsepower. But why is it so valuable?

The 4BT sports a much smaller displacement—239 cubic inches—compared to its larger sibling, the 6BT, which boasts 359 cubic inches. This reduced size means the 4BT naturally struggles with low RPM torque. Low-end torque is critical for efficiently spooling a large single turbocharger. Compound turbocharging compensates for this by using a sequence of two turbos, allowing the 4BT to generate significant power from low to high RPMs without sacrificing drivability.

Mild head porting and larger valves can indeed aid turbo spool-up in a single-turbo setup, yet they’re not always enough for those seeking substantial horsepower boosts. By employing compound turbos, the 4BT benefits from improved air intake and exhaust flow, leading to quicker spool-up times and superior performance across a wider RPM range.

The primary reason for choosing compound turbocharging is to maintain a balance between high performance and everyday drivability. A single large turbo can lead to turbo lag at low speeds, making driving less smooth. Compounds eliminate this issue, providing seamless acceleration by engaging a smaller turbo at low RPMs and the larger turbo at higher speeds, ensuring that the engine remains responsive and powerful under all driving conditions.

By tackling inherent displacement challenges, enhancing spool-up, and providing a perfect balance of power and drivability, compound turbocharging unlocks the 4BT’s full potential.

To match the new piston, connecting rods were developed and made from billet 4340, like those being used in all of the high-horsepower diesel engines. The new H-beam rod design is not only stronger than a factory connecting rod, but it also has a much smaller wrist pin journal, which will only work with the ACD piston. While the pistons and rods are the true heart of the Stroker Kit, ACD has also developed a host of 4BT parts to complement them and ensure true peak performance is achieved.

Achieving more than 700 horsepower with a 4BT Cummins involves several key modifications. Balanced and blueprinted engines form the foundation, ensuring every component operates harmoniously. Lowered compression is vital for handling increased boost pressures, while head work and head studs provide the necessary durability under extreme conditions. Properly spec’d turbochargers and the right fueling modifications are essential to reaching those high power levels.

Specific camshaft profiles were designed, custom cylinder head work was done, and 4BT-specific adjustable injection pump timing gears were installed. The short time between injection events on the four-cylinder engine required a slight engineering change for these parts, and ACD thinks it’s developed the perfect pieces to turn your run-of-the-mill 105-hp 4BT into a tire-shredding 800-hp monster.

These enhancements, when paired with the innovative components, create a powerful synergy that transforms the engine’s potential. Whether you’re aiming for 700 horsepower or pushing beyond, these modifications ensure your engine is ready to perform at the highest level.

Key components for ensuring reliability at elevated power levels include a thoroughly balanced and blueprint-engineered setup, durable head studs, and precision-engineered turbocharging and fueling systems.

Because this engine will run higher boost pressures, the cylinder head will be machined to use a custom fire-ringed head gasket kit and ARP head studs. The factory rocker pedestals must be machined for clearance to accommodate the stronger ARP hardware.

Elevated boost and cylinder pressure create a challenging environment for any engine, particularly in a 4BT Cummins. While six head bolts per cylinder might suffice under normal conditions, these pressures call for additional reinforcement to prevent a blown head gasket.

Replacing the traditional head bolts with studs is crucial, as it enhances the head’s ability to maintain a tight seal under stress. The use of ARP head studs is a strategic choice, offering the durability required to handle the increased demands. This approach not only bolsters the engine’s structural integrity but also ensures that combustion remains consistently contained, even as boost levels rise.

In scenarios where boost pressures soar, such as those with compound turbo setups achieving upwards of 70 psi, implementing fire-rings or O-rings can provide an extra layer of security. This step further ensures that the combustion process remains controlled and efficient, safeguarding the engine’s longevity and performance.

The 3.9L 4BT Cummins diesel engine has become an extremely popular platform for conversion projects throughout the past couple of years, and for good reason. Sharing virtually every internal and external piece with its big brother, the 5.9L 12V Cummins found in the 1989-98 Dodge Ram pickups, and coming as regular equipment in hundreds of commercial and industrial applications, parts availability, power potential, fuel mileage, and the lack of electronics make it an easy go-to engine when it’s time to squeeze a diesel platform into the frame rails of just about anything.

When it comes to unleashing serious horsepower from the 4BT, the cornerstone of any build is the injection pump. The Bosch P7100 injection pump stands as the undisputed choice for enthusiasts aiming for high performance. Unlike the single plunger VE rotary or the A-series inline pump, the P7100 offers the capability and reliability needed for pushing the limits of the 4BT.

By integrating the Bosch P7100, builders can tap into the 4BT’s full potential, ensuring that this compact yet powerful engine delivers the performance enthusiasts crave. Whether for racing or robust daily driving, choosing the right injection pump is key to unlocking next-level power and reliability.

Yes, a modified P7100 is used in a high-performance Chevy build, illustrating its practicality and effectiveness in real-world scenarios.

A modified Bosch P7100 can flow significantly more fuel—425cc compared to the 135 to 180cc range of stock models—making it far superior for performance applications.

The P7100 injection pump is central to performance enhancement, as it is the foundation upon which all high horsepower modifications are built.

The Bosch P7100 is preferred because other pumps like the single plunger VE rotary and the A-series inline pump do not provide the necessary performance for high horsepower builds.

The Bosch P7100 injection pump is the go-to choice for achieving high horsepower with the 4BT engine.

With comprehensive modifications, the engine can achieve more than 700 horsepower.

To push the 4BT’s horsepower beyond 400, modifications such as lowering compression, enhancing the cylinder head, adding head studs, selecting the right turbocharger, and making fuel system adjustments are recommended.

Share Link