John Mata Jr.

.

August 07, 2025

.

F100 Builders

.

Solomon Lunger

John Mata Jr.

.

August 07, 2025

.

F100 Builders

.

Solomon Lunger

TOM Bennett is no stranger to modified cars and trucks. In fact, his history with customs is deeply rooted in the mini truck scene. As Tom got a little bit older, his interest in vehicles didn’t change much, although he was more determined than ever to find a classic pickup that he could learn to customize on his own. Tom had relied on shops to dial in his rides in the past but he wanted to break away from the pattern of hiring others to do the work he knew he could handle in his home garage.

The search through local Florida classifieds didn’t prove helpful for Tom. All he found was a bunch of poor condition trucks with high price tags attached. Tom widened his search settings and found this seemingly amazing 1961 F-100 in Texas at an almost unbelievably low price. “I figured it was a scam or something, but I reached out to the seller anyway”, Tom admits. After multiple messages went unanswered, Tom asked a friend in Texas to try contacting the seller. Unfortunately, he didn’t have much luck either. “I figured the listing was too good to be true, so I just tried to forget about it”, Tom adds. “Then one day I got a call back. The seller gave the listing some time to weed out potential scam callers ironically. My friend went to look at the truck, reported back to me that it was good to go, and helped load and ship it to my place.”

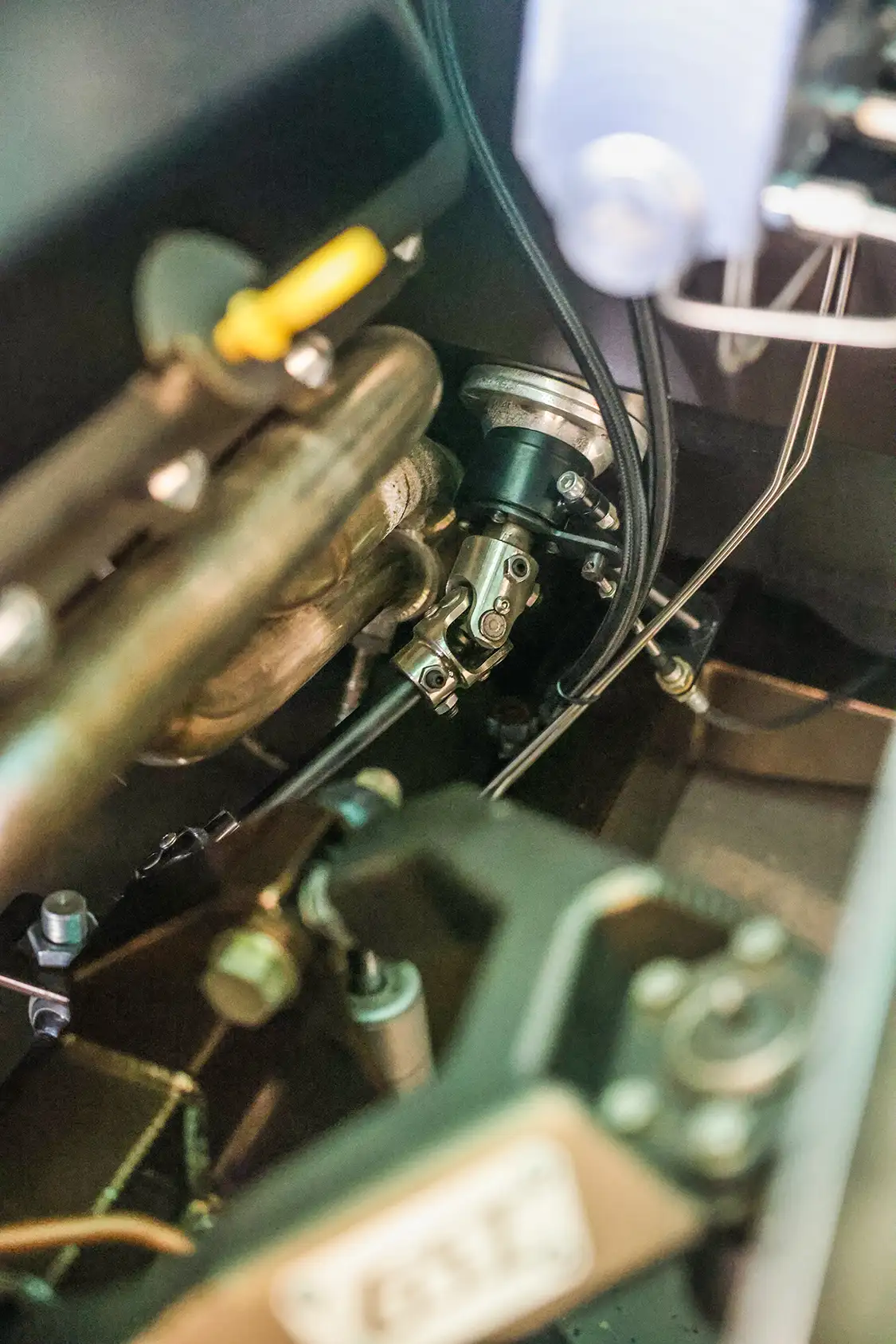

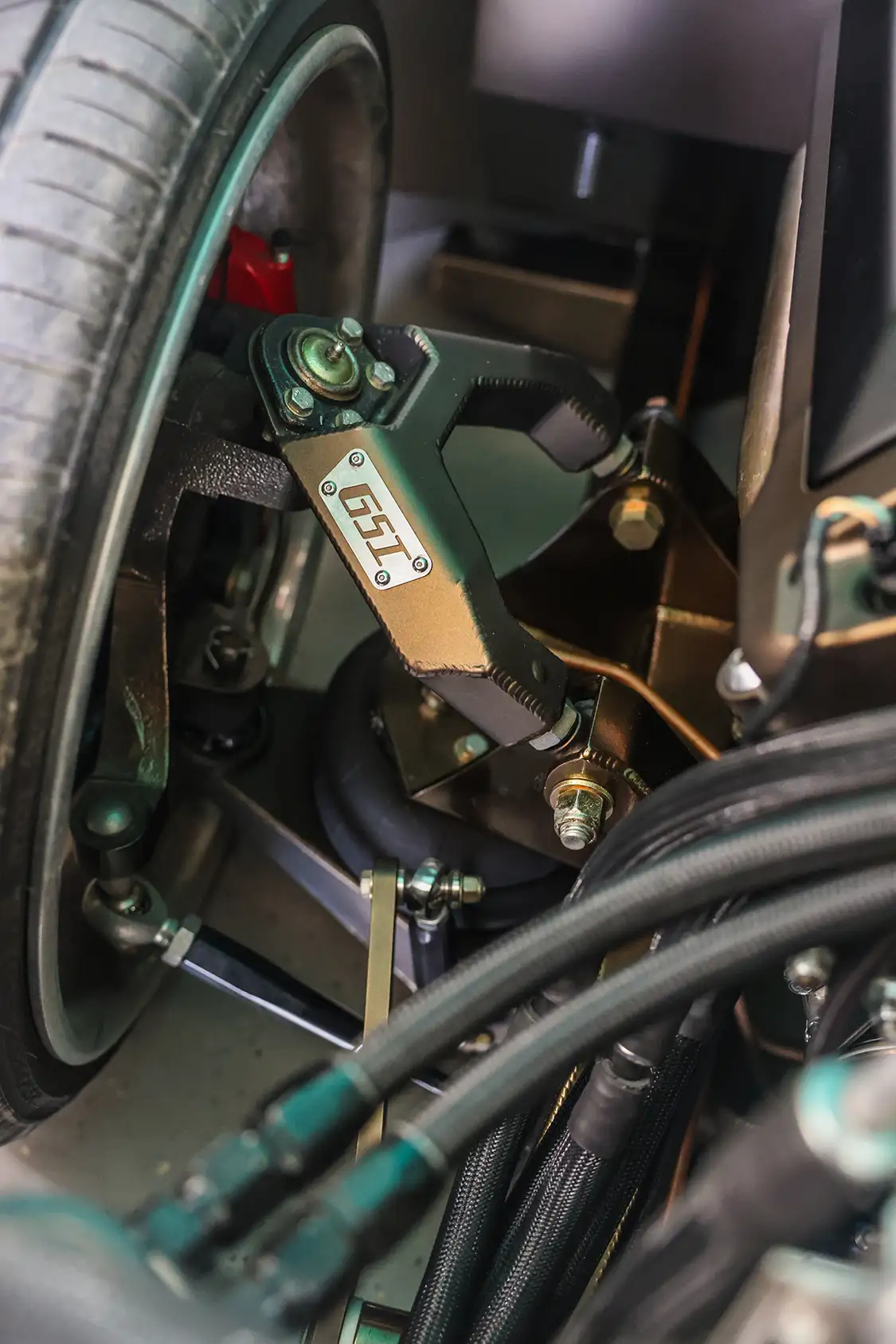

Tom already had an idea of what he wanted to do with the truck, and once it arrived, he wasted zero time disassembling it. Tom was mainly interested in the F-100 body, so attempting to salvage the existing frame or drivetrain wasn’t a priority for him. Tom had already placed an order for a new one-off frame from GSI Machine that would allow his Ford to lay out smoothly and ride low comfortably. Using a modest Harbor Freight winch in his garage, Tom was able lower the 1961 F-100 shell onto the freshly powdercoated chassis by himself, even though maneuvering the unibody was a bit awkward to handle. From there, he was able to install the rest of the air ride components, hook up the CPP big brake packages, and mount the 22-inch Raceline Desperado wheels.

From there, Tom moved onto the next phase of the build, which was dropping in a new engine—a first-gen 2013 Ford Coyote engine! He paired the modern power plant with a Ford 6R80 transmission from Power by the Hour. After modifying the core support for a new radiator, everything else fit just fine. It was at this point when Tom realized he really could do everything he always thought was outside of his comfort zone and skill level. “Even though some things took an entire day to get done, all I really had to do was to be patient, figure out what had to be done and how, and I was able to make my way through the task at hand.”

Tom already had an idea of what he wanted to do with the truck, and once it arrived, he wasted zero time disassembling it.

The next thing Tom figured out was how to make a new sheetmetal floor pan for the cab, which included fabricating a 3-piece transmission tunnel. After some trial and error, it ended up working out perfectly. Once a round of light bodywork was taken care of, Tom then moved onto one of the most impressive portions of the project—creating a unique wood plank bed floor. A prefab aftermarket kit wouldn’t do, however. Instead, Tom chose to go another route using 30-year-old Dade County pine that came straight from a friend’s barn that was being torn down. “Dade pine isn’t all too common in Florida anymore”, Tom says. “A lot of houses here were made from this wood in the 1930s-1940s, and most are still standing strong today. This wood was hard to cut, but after some persistence with a table saw, I was able to get it done—including making a center panel of the bed that actuates upward.”

The build process was rolling along steadily but a little too slowly for Tom to realistically meet his goal of unveiling the F-100 at the Mini Truckin’ Nationals show in Maggie Valley, North Carolina. To help speed things along, Tom called on a few local businesses for reinforcement. “Blast Coating in Lake Worth joined the project by coating a few interior pieces, as well as some individual suspension components”, he reports. “Shaun Stoger and Bryan Cawthon at Aspire Autosports in Clearwater contributed with their expertise in wiring the entire truck and painting the firewall and grille. Jessie and Aaron at Innerworx handled the upholstery work on the factory bench seat and all throughout the cab. Eric Cryan at Advanced Audio Concepts then stepped in to install and wire the audio setup and other electronic additions in the cab.”

The wave of assistance ensured Tom would ultimately meet his debut deadline. While there’s no doubt that he could’ve made even more progress on his own, he recognized that his pace was no match for a ticking clock. With little else to do before packing up for the big show, Tom was stuck by a sudden thought of what to name his F-100. “I woke up in the middle of the night and thought ‘Chicken Run’, which I shortened to CHKN RN for the license plate”, he says. “My dad used to buy my daughter a baby chick every Easter, and we still have most of them. The name fit the loose farm truck theme and was a cool way to give the truck some personality. In a matter of two years or so I was able to wrap up the build. I’m thankful for all the help I received at the end and am proud of how much I accomplished at home to start it off. I don’t think it came out too bad for my very first all-in project.”

Even though some things took an entire day to get done, all I really had to do was to be patient, figure out what had to be done and how, and I was able to make my way through the task at hand.

Engine & Drivetrain

Chassis & Suspension

Wheels, Tires & Brakes

Body & Paint

Interior & Stereo

Share Link