Alan Galbraith

.

January 15, 2026

.

Features

.

ALAN GALBRAITH

Alan Galbraith

.

January 15, 2026

.

Features

.

ALAN GALBRAITH

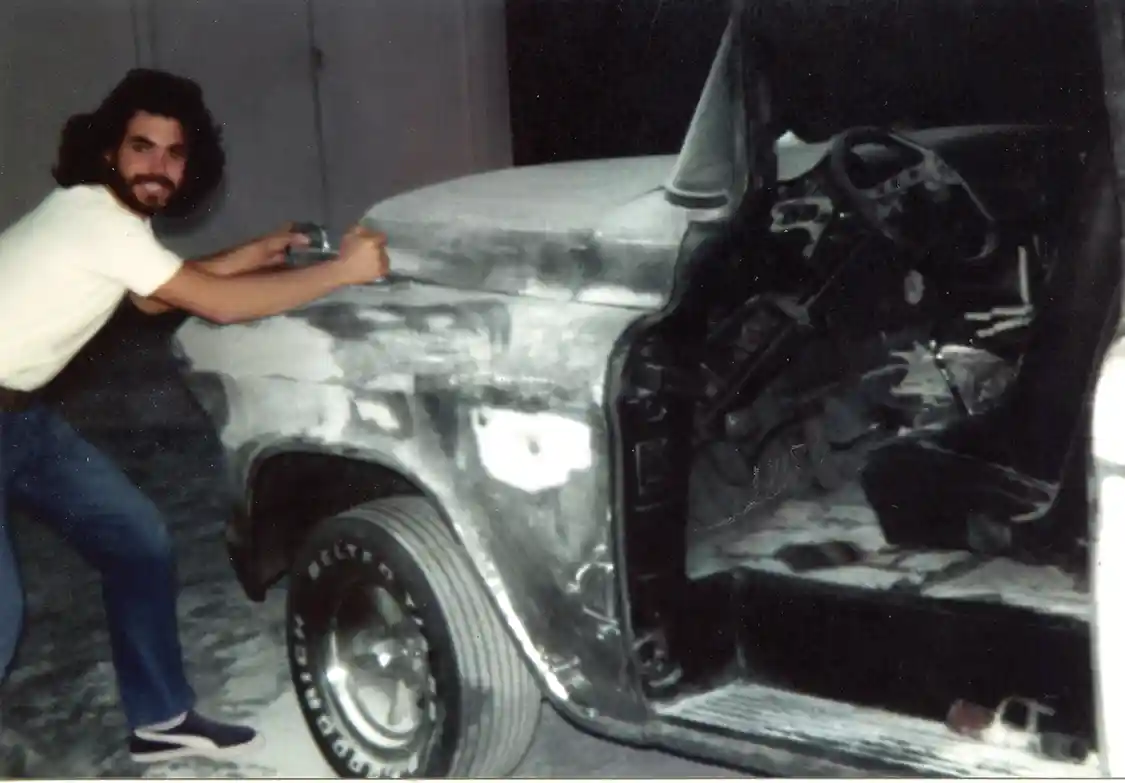

When Dennis Shanahan bought his ’55 Chevy at 17, he had no idea it would take him 37 years to make it into the truck he envisioned. Dennis entered auto body trade school right out of high school in 1974. He purchased the nose high, gasser- looking Chevy with a 265-ci engine and Muncie four-speed and drove it to and from school. The plan was to make it his shop truck when he graduated and opened his own business. To practice his newly learned skills, Dennis sanded down and painted the truck while still in school. After graduation, he tore the truck down to do an engine swap, but his new business took off quickly, and the project was relegated to a dark corner of the shop in 1976.

Sometime in the ’90s Dennis found the time to start work again on the old shop truck. He mounted a Camaro subframe and suspension to the front of the frame, while the Camaro’s TPI engine found a home under the hood. Once again, the demands of a successful auto body shop got in the way of personal projects, and the truck was again pushed into the corner. It sat long enough for Dennis to come up with a different vision for the truck, and he began the project anew for the third time. The Camaro subframe chassis and motor were sold, and an ’80s C4 Corvette was selected to donate its suspension, motor and transmission to a new chassis. But yet again, business took precedent and the project was pushed aside.

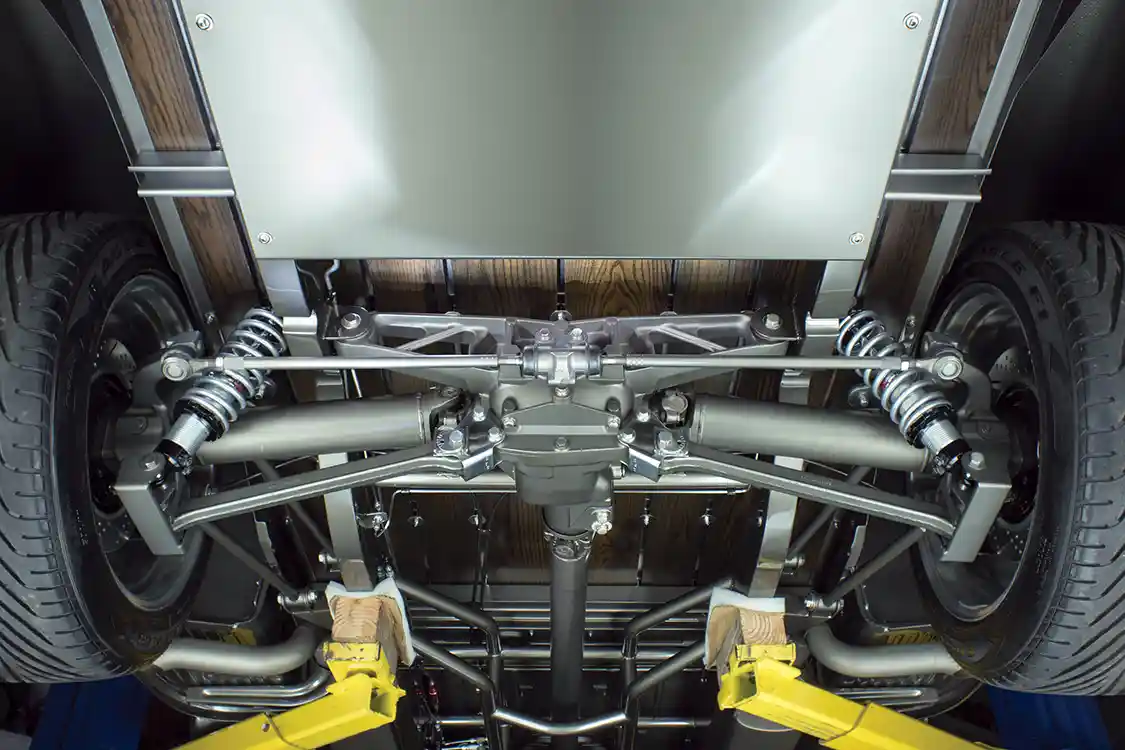

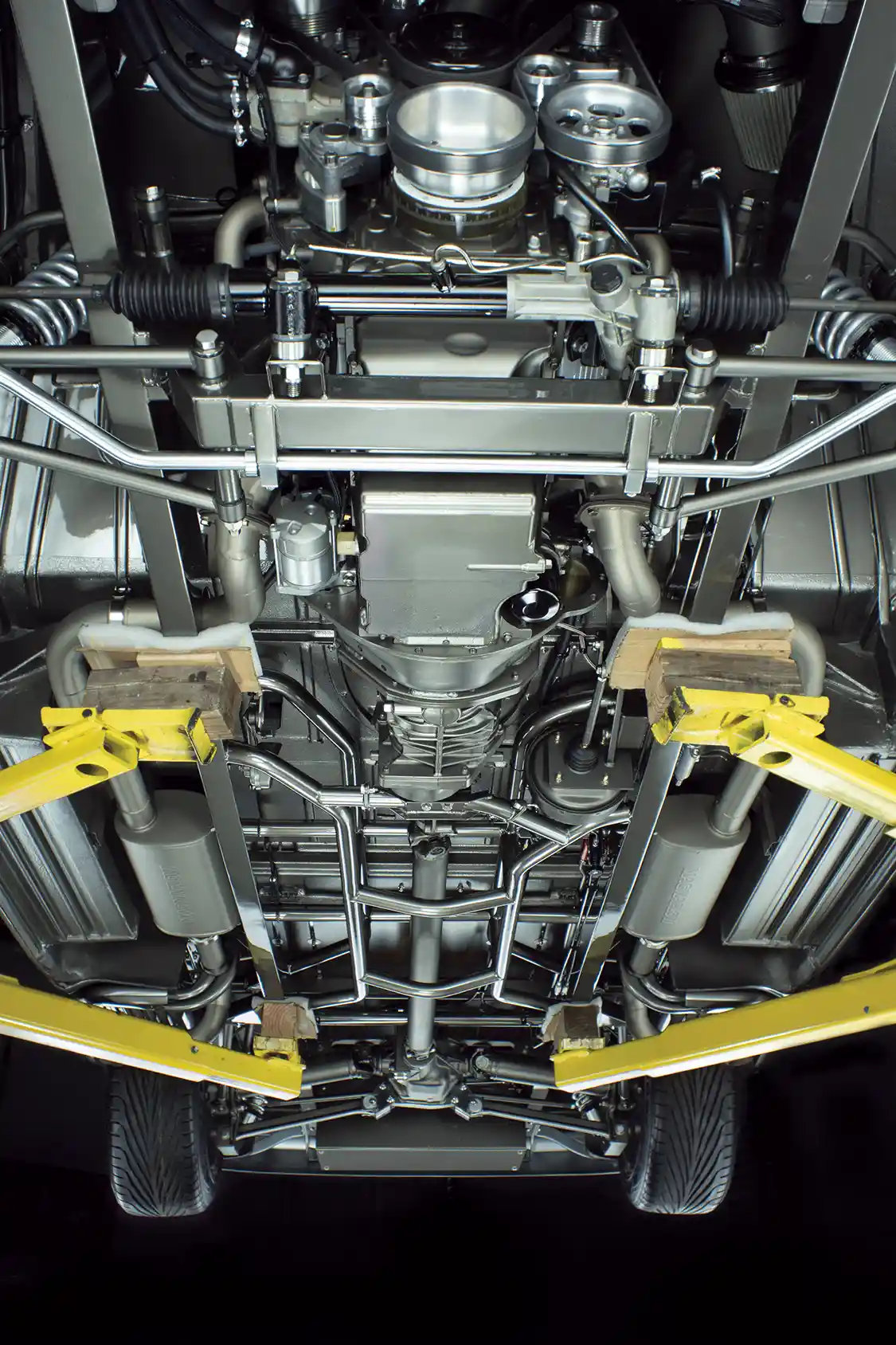

After decades of the truck lurking in the back of his shop, Dennis reached the point where he had some time to work on his long- suffering project. Even then it took some prodding from friends and family to finally get things rolling. His wife Debbie gave him an LS2 crate motor for his birthday, with the caveat that it found a home under the hood of the Chevy. Not happy with the stock frame with the Corvette components grafted on, Dennis tapped Street Rod Chassis Builders in Oregon to build a chassis from the ground up to accommodate the sports car suspension front and rear and make a nice home for the LS2. A Tremec TK600 five-speed was fitted to the flywheel via a McLeod clutch to transmit the power back to the C4 Corvette rearend. The body was set on the frame for the first time in years for mock-up only to reveal that the truck didn’t have the ride height that Dennis wanted. Wanting to keep airbags out of the build meant that Dennis set about raising the shock towers in the front and sending the rearend out to Roseville Rod to shorten the mounting ears so that the rearend could be mounted inside the frame rails instead of under it. The stock dog bones were replaced with a completely adjustable 4-link to secure the rearend. With the Corvette leaf spring eliminated, custom brackets were made for the coil-overs. All other unused stock rearend mounting points were cut off and ground smooth.

With the chassis finally sorted, Dennis turned his attention to the body. He wanted to keep all of the original sheet metal and maintain an easily recognizable ’55 Chevy look while improving on the factory metal work. The first order of business was to weld up and fill all of the factory spot welds and seams, giving a much smoother look. Starting at the front, the upper grille panel and latch panel were welded together into one piece. The stock firewall and inner fenders were retained, but their factory stampings were smoothed and all holes (Dennis counted 102 of them in all) were filled. All hoses and wires were routed under the cab. The cowl vent was smoothed out and filled as well. The stock hood hinges where re-riveted flush and smoothed. The front bumper was flipped to put the visual weight of the bumper down low. The ends were slightly reshaped and all of the mounting bolts were mounted flush and smoothed. The upper corners of the doors at the cowl were rounded and one-piece windows were fitted. The door handles where shaved, and the door gaps were made even by welding on a rod and grinding it down. Dennis also drilled out the door hinges, installed bronze oil-less bushings and made his own pins. The latches and strikers were reversed so that the solenoids could be placed in the cab frame, while the sill steps inside the cab were all molded. Finishing the metal work inside the cab, the dash was welded to the windshield posts and completely smoothed.

Back outside the cab, the drip rails were pounded down, extended in the front and molded in with rod stock. The original bed sheet metal was retained, and all factory stampings were smoothed. The stake holes and bed rail ends were filled. Dennis sourced a second set of rear fenders and cut them 1.5 inches out from the bolting flange and added that to the originals, widening them with only one weld. The steps were cut and wedged out using a second set of steps to fill the gap. The factory embossing’s were then reshaped to match the widened fenders. The tailgate was completely molded with hidden latches installed. The factory logo stampings remain, although in heavily massaged form. The rear bumper was flipped, the license plate dimple filled with a section of front bumper and all bolts were molded in and smoothed. The bumper’s upper lip was extended so that it tucks up against the body neatly. The outer edges were reshaped, but with the fenders extended, the stock width now fits them nice and tight. Once all of the flipping and filling was done, the stock taillights were relocated to finish off the look. Inside the bed, the floor was raised ¾ inch to clear the rearend, and then the oak boards received six coats of ebony stain followed by six coats of Varathane finishing product and a satin automotive clear.

After every surface inside the bare cab was covered in Dynamat, Dennis had Dave Putnam covered a pair of Glide Engineering seats, the custom console and rear enclosure with Italian leather. A Classic Instruments gauge panel was the only thing fitted to the smoothed out dash; all other controls were mounted behind hide-away panels in the console. The battery, stereo amp and engine CPU were hidden in the rear enclosure. German weave carpet was sourced to give a refined look to uncomplicated interior.

After the build was done, Dennis blew it all apart one last time to prep everything for paint and finishing. Dennis’ shop took in an Audi for some collision repair and he fell in love with the Alpaca Beige Metallic paint. He wanted a fairly subtle look for this truck, so all of the once-chrome pieces were painted and scuffed for a brushed look. Everything that could be unbolted from the chassis was glass beaded, painted, and then covered in flat clear to make it stand out from the glossy body and frame. The engine and transmission received the same paint and flat clear treatment. Stainless steel fasteners, which were used throughout the build, were ground smooth and brushed. The Sanderson headers were stripped and powder coated a contrasting gold/bronze. Mike Cline applied the only pinstriping and lettering on the truck to the carbon fiber engine cover using brown and beige paint in a style that mimics the original valve cover font.

While the truck was originally intended as a shop truck, it just kept getting nicer and nicer as the build went on. Dennis remarked that after waiting so long to do it he wanted to do it right. With the project finally finished, Dennis took the truck to several shows, where it won just about every award it could. Now he intends to use it, although he admits it’s too nice to be his shop truck anymore.

OWNER

Dennis Shanahan

1955 Chevy Pickup

Sacramento, CA

ENGINE:

SUSPENSION:

WHEELS AND TIRES:

BODY & PAINT:

INTERIOR:

SPECIAL THANKS FROM THE OWNER: Kail Withers, Eric Evenson, Ronnie Bunker, Terry Lyttge, Shanahan’s Auto Body crew, Debbie Shanahan, Steve

Share Link