BOB GRANT

.

December 31, 2025

.

Drawings

.

BOB RYDER

BOB GRANT

.

December 31, 2025

.

Drawings

.

BOB RYDER

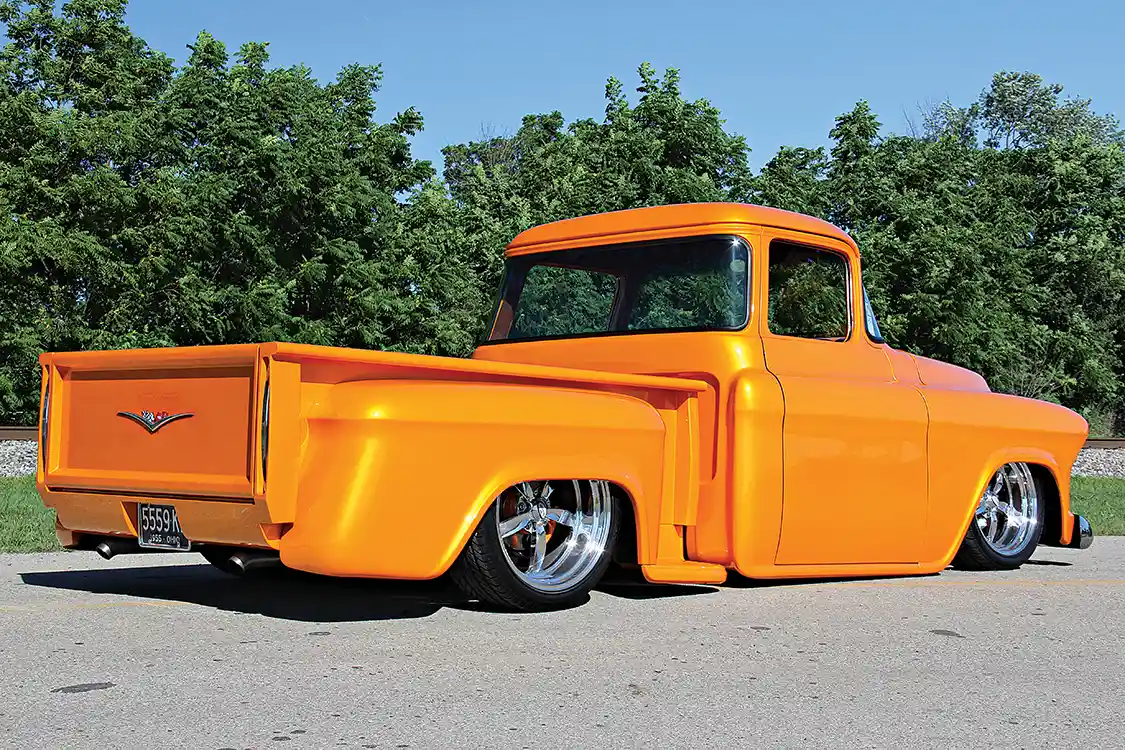

Cincinnati’s Mike Krummen’s home-built hauler took 15 years to complete. While cruising the back roads of Vevay, Indiana, Mike noticed a rough ’55 Chevy small window, ¾-ton, long bed protruding from a wooded area with a faded “For Sale” sign in the window. After throwing down a Grover Cleveland bill in exchange for the pink slip, he actually drove it home. A year went by before Mike broke out any tools to begin his project, though, and it didn’t take long once he got started to determine that there wasn’t much worth saving. The only salvageable original parts were the frame, cab and doors. The rest was junk.

Before Mike got started, he knew exactly what he wanted his truck to look like when it was finished. He loved the stock appearance of the ’55 big window short bed. He wasn’t going to chop the top, section the cab through the doors or pancake the hood. The truck cruised down the road spinnin’ custom wheels and tires at stock ride height. When Mike would park it, the ’55 would lay on its rockers, tucking tire and wheel deep into the fenders. Under the hood, he wanted an LS1 power plant backed up to a 4L60E automatic transmission. Of course, being a painter by trade, he planned to have a killer paint job that would turn heads and drop jaws. His dream truck would be pearl orange. Opening suicide doors would expose a fully custom leather interior. With those intentions, let’s find out how Mike’s ’55 became a reality.

Mike utilized the ’55’s ¾-ton long-bed frame and welded in a Fatman Mustang II front clip with Heidts 2-inch dropped spindles and Scott’s Hotrods upper control arms. To achieve adjustable ride height with layout capabilities, Mike installed a pair of Firestone pneumatic ’bags at all four corners. Front and rear braking were updated with a set of late-model GM disc brakes with 11-inch rotors and dual-piston calipers that were linked with stainless steel brake lines. Steering was improved with a Flaming River power rack with a Flaming River chromed shift/tilt steering column capped with a Billet Specialties Stiletto half-wrapped tan leather billet aluminum steering wheel. The frame’s back half was cut to a short-bed wheelbase. The frame rails were bridge-notched to accommodate the airbagged rear suspension, allowing it to lay out. A 1969 Camaro 10-bolt rearend housing was fitted with 3.73 gears and a posi-unit. Mike designed and fabricated his own triangulated- wishbone four-bar rear suspension to anchor the rearend. Spinning style and grip was accomplished by bolting on a set of Boyd Coddington New Wave 18×8 front and 20×10 rear polished aluminum wheels wrapped with BF Goodrich 245/45- 18 front and 275/40-20 rear rubber.

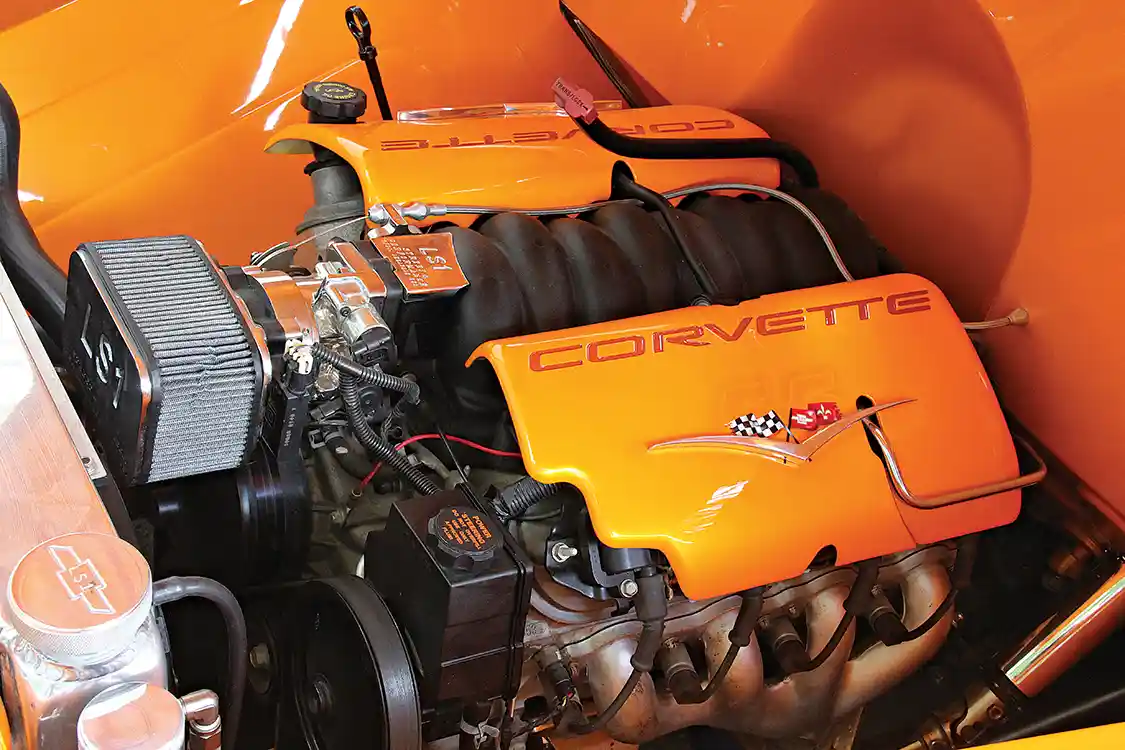

Mike located a 2002 Pontiac Trans AM with only 700 miles on the odometer, with an unmolested LS-1 engine and 4L60E automatic transmission that he extracted. The low-mileage power train was bolted in between the ’55’s frame rails. The factory exhaust manifolds were bolted up to a 2 ½- inch-diameter stainless steel exhaust that flows into a pair of Flowmaster Hush Power II mufflers. When Mike decided on the Corvette theme, he dressed the LS-1 with a pair of stylish Corvette valve covers. The LS-1 horsepower was linked to the rearend via a Cincinnati Driveline driveshaft. Installing a custom Street and Performance aluminum radiator cools the engine and transmission. A No Limit 20-gallon stainless steel fuel tank with internal fuel return and pump was plumbed to the healthy LS-1 power plant. When Mike hammers the loud pedal, the LS-1 instantly comes alive with a vengeance.

Of course, Mike used his professional body and paint talents to perform some body mods. He always wanted a rear big window cab to fulfill his Nemo in an aquarium fantasy. One of Mike’s buddies told him of an old rusted out 1955 big window cab that was abandoned on his property in the woods. He told Mike if he could drag it out, he could have it no charge. After dragging home the rusted out carcass, Mike drilled out the spot welds around the big rear window inner structure and door jambs. Then he carefully cut just underneath the roof’s drip rail. Making another cut below the big window about 8 inches at the bodyline allowed him to remove the cab’s big window and B-pillars. After removing the original cab’s small window/rear cab section, the big window was trimmed, fitted and welded into the original cab.

Thinking he would save time by purchasing new aftermarket front fenders and a hood, he quickly realized that was a mistake. Nothing came close to fitting properly. The gaps were way off with no way of adjusting to a tighter tolerance. In frustration, Mike decided to take a break and walk away from his ’55 project for a while.

About four years ago, Mike’s oldest son started to take an interest in custom cars and trucks. So, Mike decided to get back on the ’55 project. In fact, he set himself a goal to have it finished by New Year’s Day 2013.

First, he needed to get the front-end sheet metal fitted and aligned, and then have the rest of the bodywork completed. Mike decided to suicide the doors and shave the door handles. He cut 2 inches off the front of the hood and added it to the upper grille to make a new valance for a new style hood latch. Mike fabricated and installed a pair of custom rear wheel tubs and a custom smoothed rear roll pan that was placed cleanly underneath the tailgate. A pair of Cadillac vertical taillights flanks the tailgate. The bed was also fit with custom wheel well tubs.

With the metalwork complete, he applied multiple coats of PPG High Build K-38 primer surfacer. Many hours were spent block sanding to get the ’55’s surface straight and smooth. Before applying the color basecoat, Mike applied a couple of coats of white sealer. After mixing a custom basecoat blend, using House of Kolors Sunrise and Sunset pearls, he filled the spray gun pot and started laying down eight coats of Tequila Sunrise. After the color basecoat had time to dry, four coats of Sikkens Autoclear III were applied. Given time to cure, the clear was cut, buffed and polished to a deep, glistening shine. The mahogany wood bed floor was cut and sanded by Mike’s brother Steve. Mike stained the mahogany planks using the same House of Kolors Sunrise and Sunset pearls. The planks were wiped down, leaving the Sunrise and Sunset pearls in the wood grain. To achieve a dramatic appearance, Mike buried the wood with 12 coats of clear. Once the exterior was complete, Mike moved to the inside of the truck.

With the help of two friends, Jeff Redding and Eric Wunder, they tackled the audio system, installing a Pioneer CD/DVD head unit powered by two Kicker amps. The cruisin’ tunes are exhausted by a pair of Fosgate 6.5-inch speakers with tweeters mounted in the kick panels. The thunderous bass pounds out of a pair of Fosgate 10-inch subwoofers. A Dakota Digital gauge cluster and gauges were installed into the impressive custom-smoothed steel dash. A custom waterfall center console houses the Pioneer head unit, Vintage Air control panel, Air Ride Technologies control panel and electric window switches. The console separates a pair of Honda Prelude bucket seats with headrests removed. The bucket seats were reshaped with new foam and covered in Mandarin Ultra Tan leather. The custom door panels and headliner were also covered with Mandarin Ultra Tan leather. A layer of Dynamat sound deadening/heat shielding material was laid down before Mandarin nylon pile carpet was laid out.

Mike’s ’55 is definitely a timeless build that might have taken years to complete, but it was definitely well worth the wait. ST

OWNER

Mike Krummen

Cincinnati, Ohio

1955 Chevy Step Side

BUILDER

ENGINE

TRANSMISSION

FRAME

SUSPENSION

BRAKES

WHEELS

TIRES

BODY PAINT

INTERIOR

Share Link