SOLOMON LUNGER

.

July 31, 2020

.

Department

SOLOMON LUNGER

.

July 31, 2020

.

Department

In the last issue of F-100 Builder’s Guide you saw Joey and the team at Evolutionary Rides take our ’72 F-100 Oscar The Bump off the frame, strip the frame down to the rails and install the QA1 front suspension.

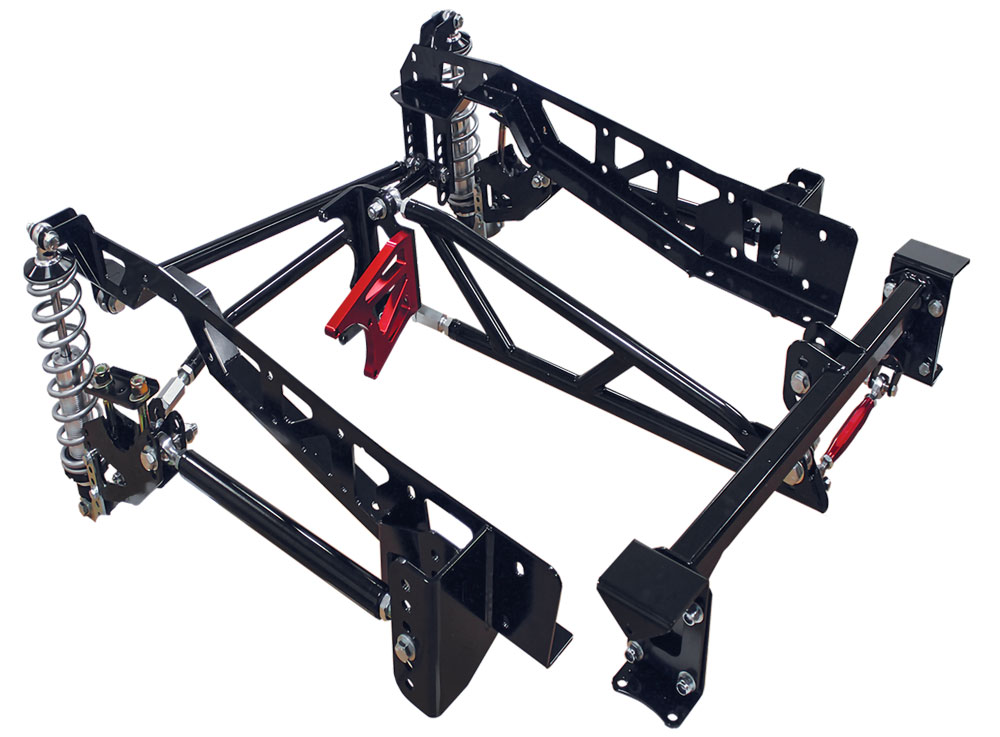

Because we’re emphasizing performance in this issue, we’re going to show you how the QA1 rear suspension setup goes together in a ’65-’72 truck. We were very happy to be ditching the factory leaves and installing a torque-arm style rear setup. Why? For one, it maximizes performance while minimizing suspension bind. And two, from speaking with the knowledgeable techs at QA1, we are definitely excited to take this onto a track and around some corners.

This complete bolt-in system adds unprecedented adjustability to your truck without any welding. It can be installed in any home garage and can even be done with the bed still on (if you’re not in the middle of a restoration project like we are). You can get a 4- to 7-inch drop out of this system, it is about 100 pounds lighter than the stock suspension, and it looks just as good as it performs.

Tools needed include a floor jack, jack stands, drill with ¼-inch and 7/16-inch drill bits, wrenches, ratchets and socket sets, a torque wrench, grinder or air chisel, some anti-seize and, most importantly, some cool refreshments if this happens to be a “stay at home” project. This is by no means is meant to be a step-by-step instruction set; for that you can go to www.QA1.net/F100. What this is meant to be is a guide to show you what all this system entails and why we chose to go with this setup for our project. The guys at Evolutionary Rides said that this is an easy, very straightforward install.

What we have done here might not be exactly how you’ll do it at home since we had the truck taken off the frame for our restoration. Joey and his team have installed a few of these QA1 kits already, so they certainly know some of the tricks to getting it done quickly and safely. They removed some of the crossmembers that you do not need to remove, but we are going to be adding some custom ones back in later.

We didn’t get to it yet (we will be setting ride height, and final wheel/tire choices down the road), but there will be final adjustments once we put the chassis back together after powdercoating. Last but no least, make sure that you enjoy your classic trucks and get out there and drive them!

[divider]SOURCES[/divider]

QA1 Motorsports

800-721-7761, orders

952-985-5675, tech support

www.QA1.net

Evolutionary Rides

352-835-1355

evorides@yahoo.com

www.facebook.com/evolutionaryrides

Share Link