Chris Hamilton

.

June 08, 2022

.

c10

Chris Hamilton

.

June 08, 2022

.

c10

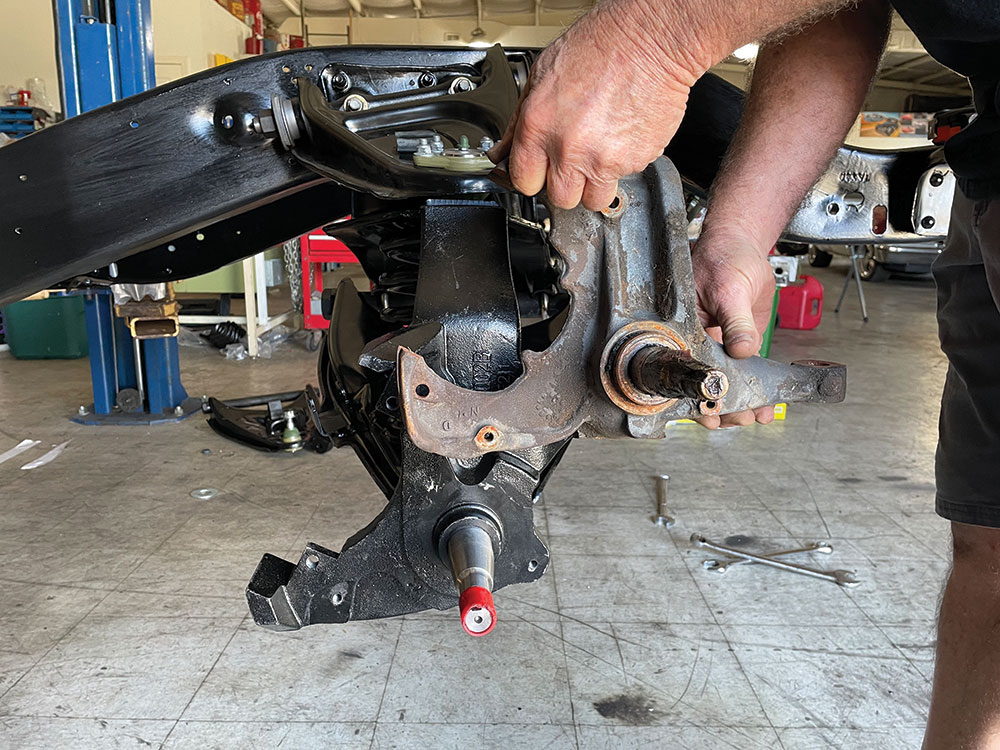

The teardown is complete and parts are finally starting to arrive at our home shop. That means it’s time to jump back on project Rocky, our slightly lifted, two-wheel drive, 1979 Chevy C10 Squarebody.

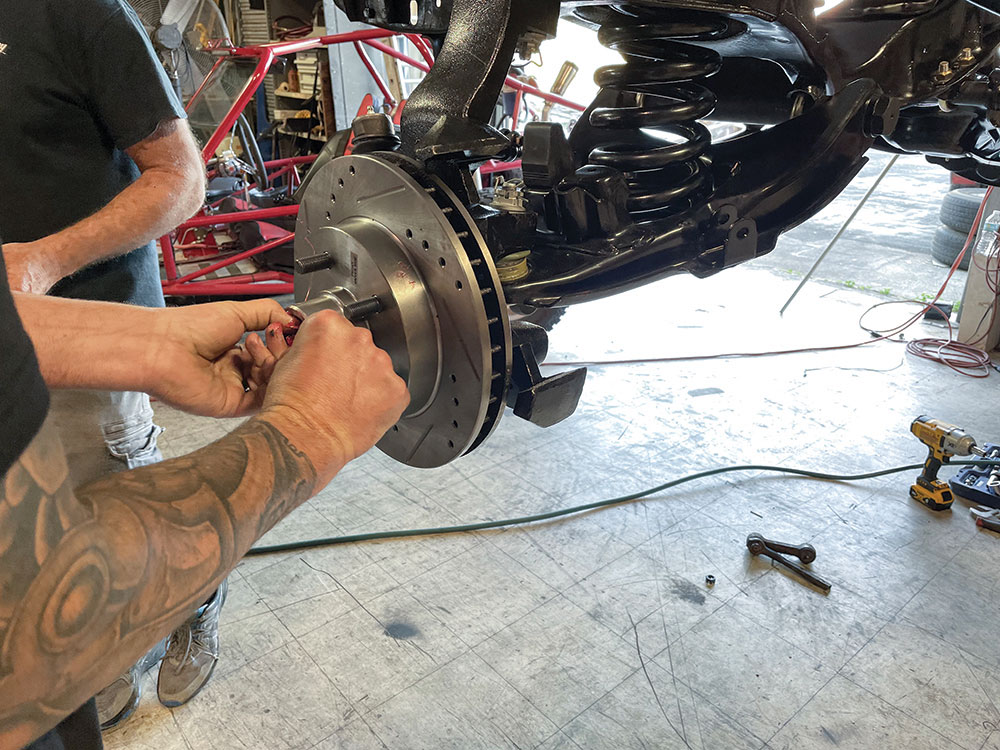

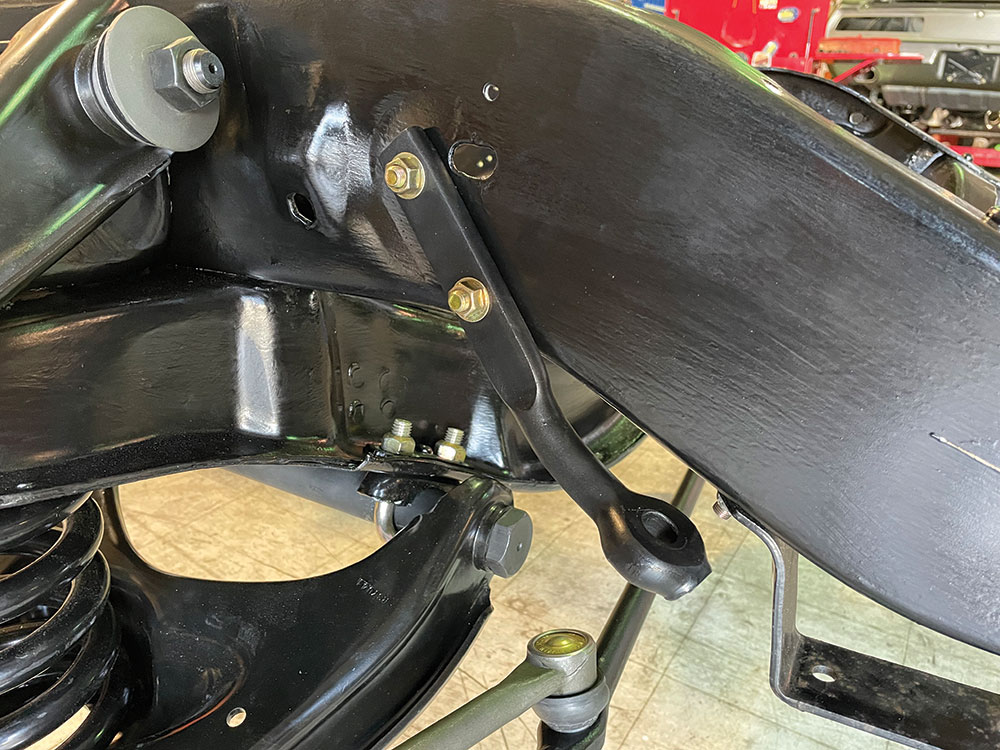

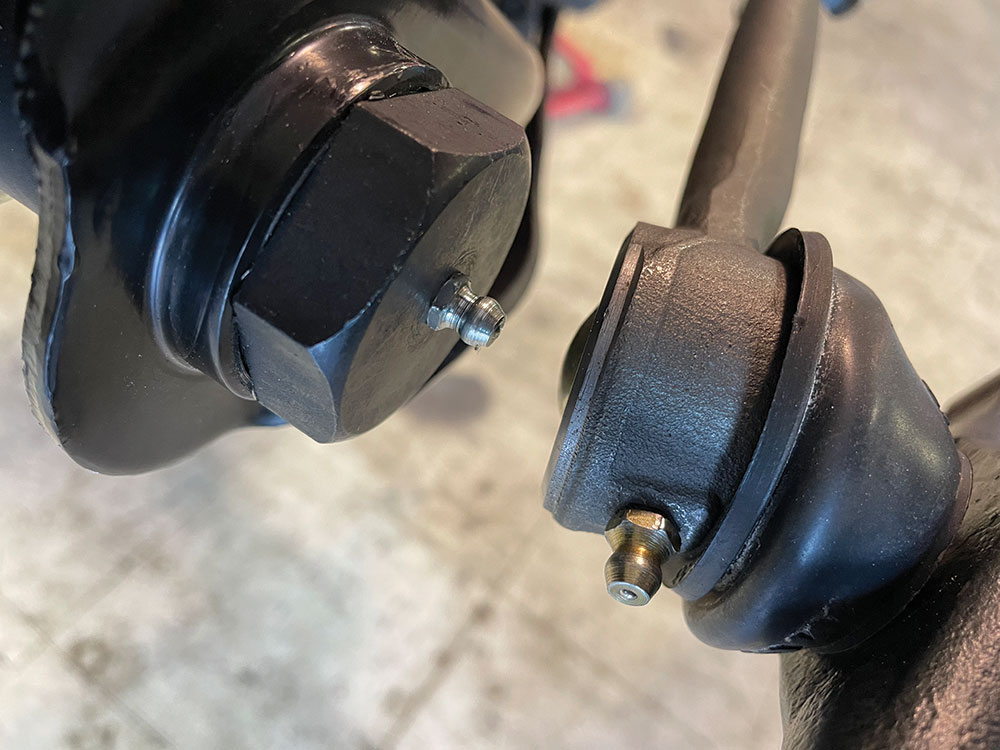

In a previous issue, we fully disassembled this truck completely down to the original frame rails. We set the original body panels aside and ordered the first group of goodies we need to rebuild including cab rocker and corner replacement patches from Auto Metal Direct, OEM factory replacement suspension parts from RockAuto.com, and a set of two-wheel drive lift spindles for an ’88-’98 Chevy C1500 OBS truck from Rough Country. This combination of bolt-on, factory spec hardware should give us around 4 inches of lift on the front of our classic two-wheel drive Chevy C10.

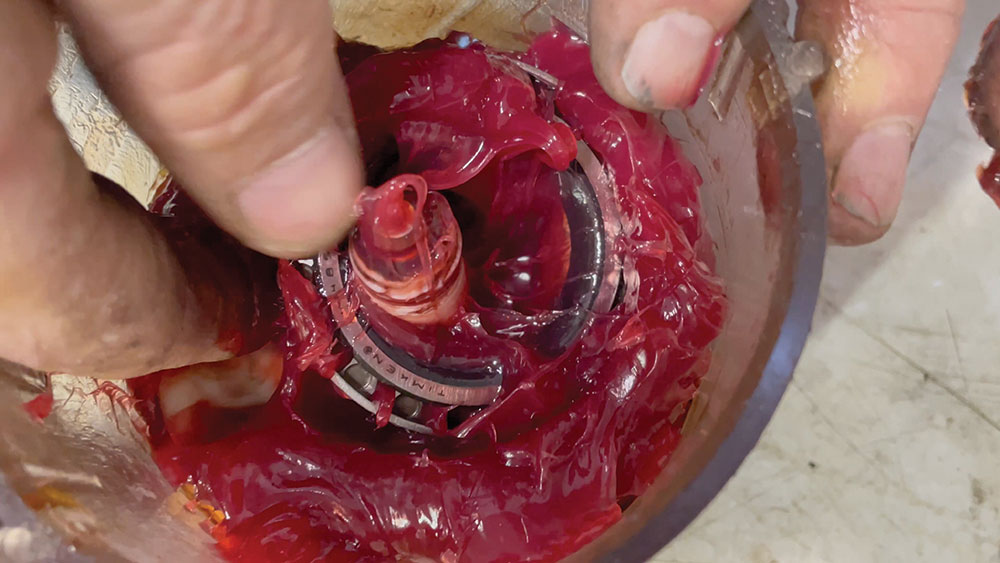

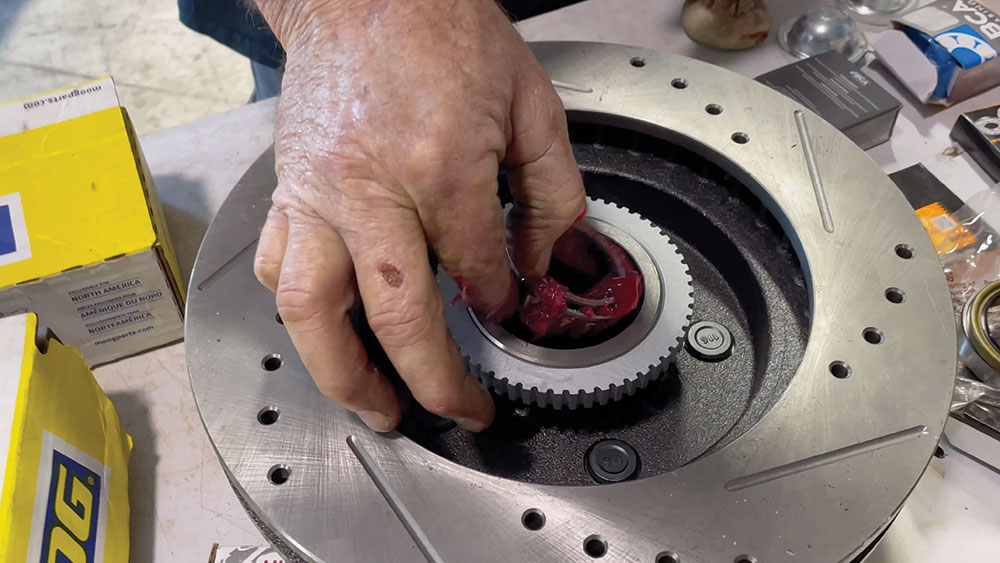

Now that the parts are patiently waiting on the workbench, it was time to get to work. The frame and rear axle have to be sandblasted down to the original metal before we can re-coat them in a new black satin finish. The frame is perfectly straight and completely flawless, so we know we have a great starting point. The goal is to get this truck to SEMA this year in the Auto Metal Direct booth. So far so good. Follow along as we fully assembled the front end including a new steering box and tie rod ends. How’s it going on your project?

Share Link