EDDY CEBRECO

.

March 31, 2022

.

Features

EDDY CEBRECO

.

March 31, 2022

.

Features

AFTER MANY YEARS OF TRAVELING TO EVENTS AND MEETING AMAZING TRUCK BUILDERS OR OWNERS, WE’VE REALIZED THAT IT’S POSSIBLE TO SHARE INTERESTS WITH PEOPLE WHO HAVE DRAMATICALLY DIFFERENT PERSONALITIES. We’ve seen some of the most impressive rolling art come out of both meticulous and messy shops, built by masters and maniacs. Their day-to-day lifestyles might be significantly different, but the one thing that they all have in common is a passion for frame-layin’, neck-breakin’ trucks.

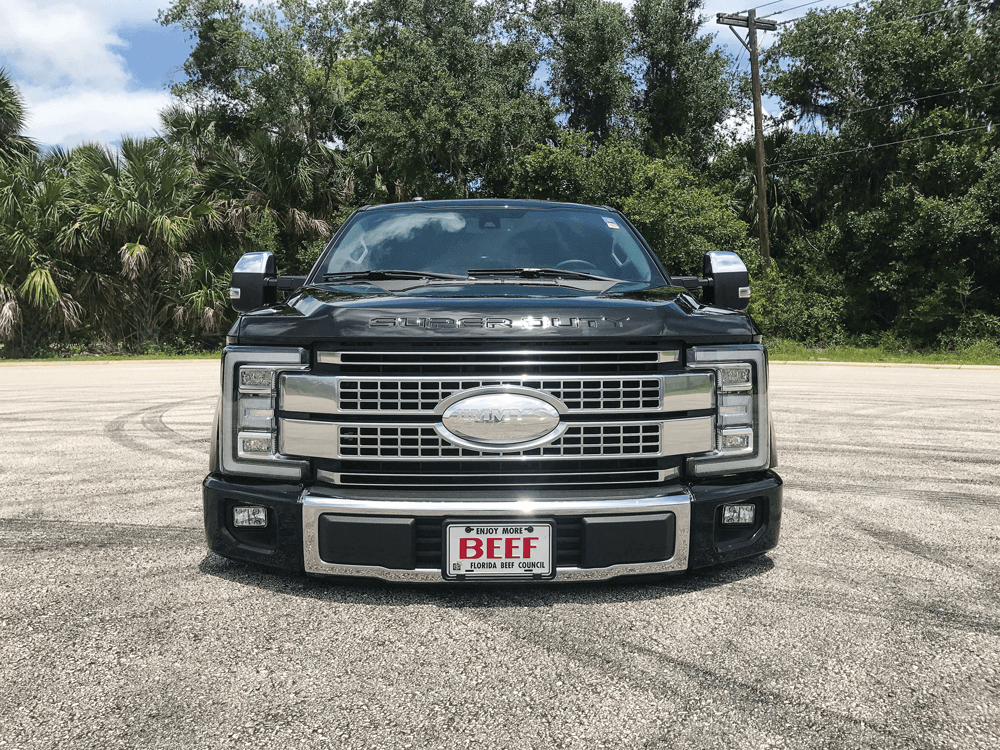

The majority of our days here at StreetTrucks are spent reviewing upcoming and recently completed custom trucks that fit our brand, which coincidentally is not a bad day’s work. We receive loads of emails full of pictures and build specs along with tons of messages on Facebook and Instagram from people who’d like to get their ride some exposure. It can be overwhelming at times, but at the end of the day it just goes to show how strong our community is. We do our best to acknowledge each and every message, but admittedly, some can slip through the cracks. Your best bet to get our attention is to include a photo of an extremely unique truck build along with some specs; perhaps a killer shot of your ’17 Ford F-350 Platinum super duty diesel that just happens to lay the pinch molding and tuck 26s, like Jeremy Smith did. This truck is so impressive that after hours of staring at pictures and debating whether they were Photoshopped or not, we decided to reach out to learn more about the build and the man behind the metalwork.

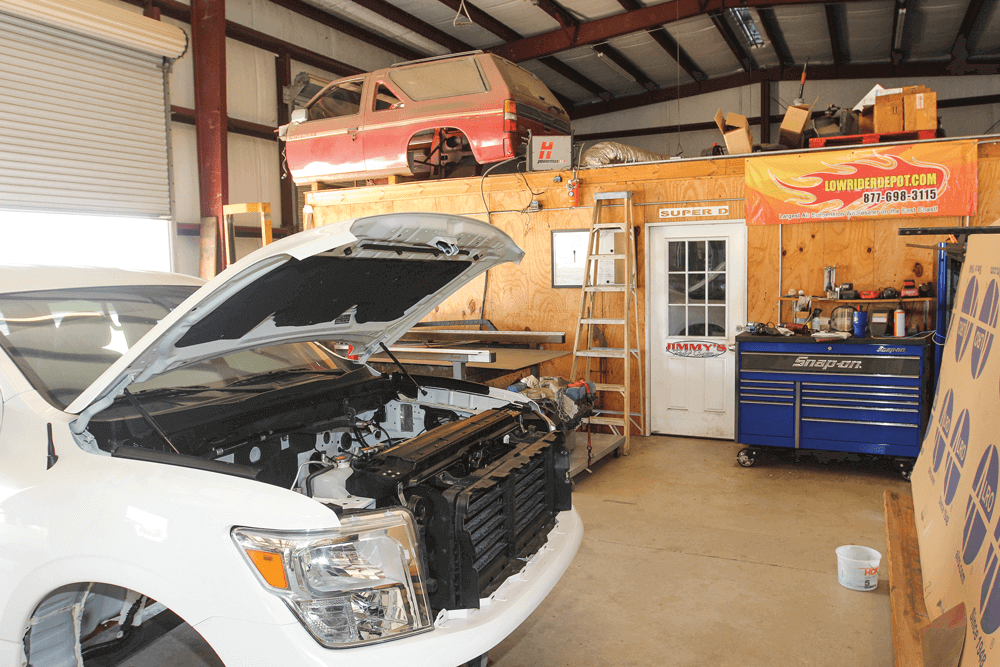

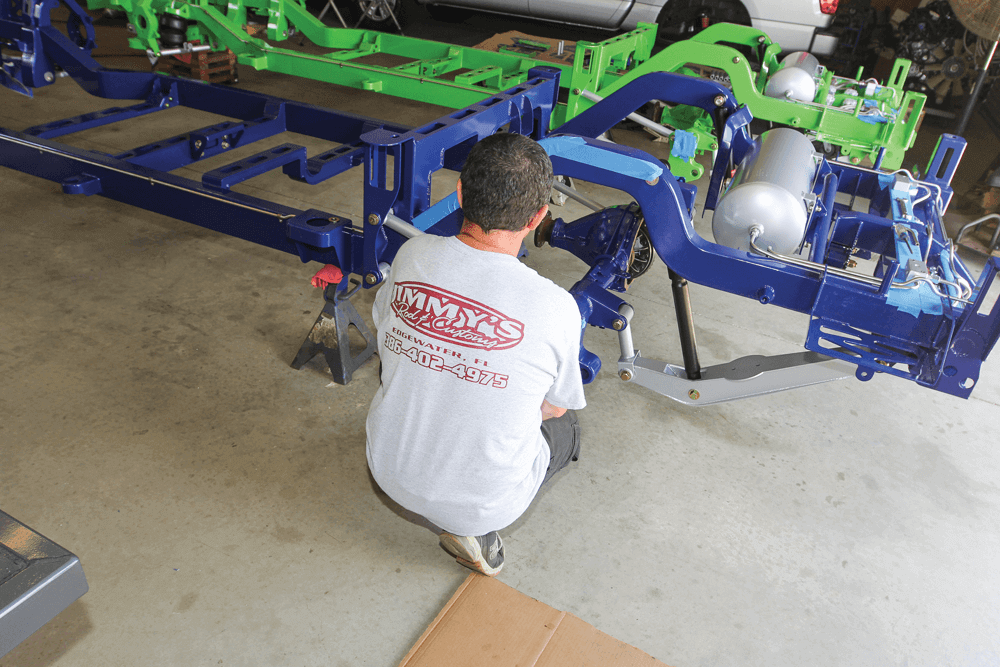

Jimmy Graham, owner and operator of Jimmy’s Rod and Customs, seems like your average everyday metal fabricator, but if you take some time to actually chat with him for an hour or so, you will quickly realize that there is genius underneath his unassuming personality. A few weeks back we got the opportunity to talk with Jimmy at his fab shop, directly in front of his current creation—or should we say creations.

JIMMY GRAHAM, OWNER AND OPERATOR OF JIMMY’S ROD AND CUSTOMS, SEEMS LIKE YOUR AVERAGE EVERYDAY METAL FABRICATOR, BUT IF YOU TAKE SOME TIME TO ACTUALLY CHAT WITH HIM FOR AN HOUR OR SO, YOU WILL QUICKLY REALIZE THAT THERE IS GENIUS UNDERNEATH HIS UNASSUMING PERSONALITY.”

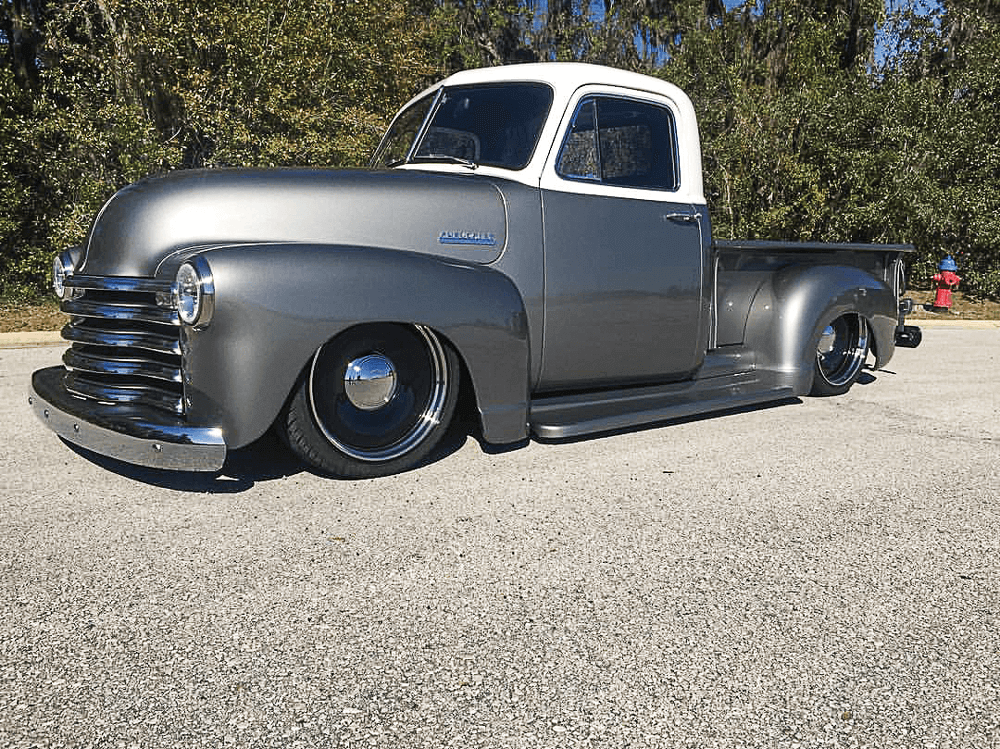

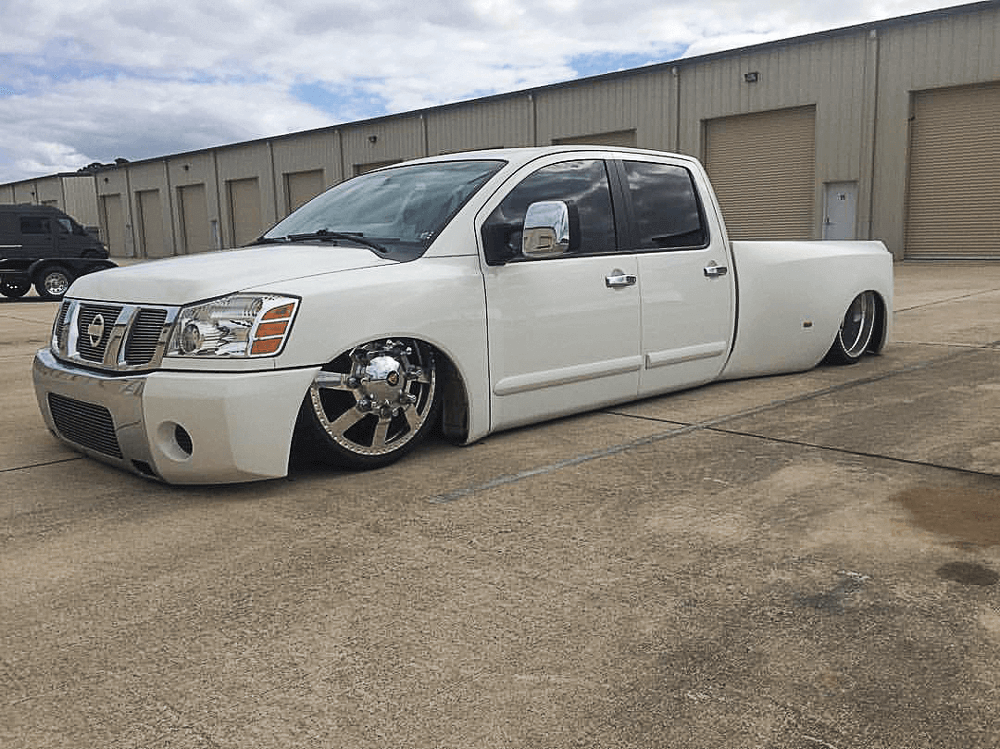

Custom-built full-plate chassis that lay fl at from front to rear have been on Jimmy’s daily to-do list for nearly 20 years. Starting in his garage working on his own Nissan hardbody led him down the path to becoming one of the most sought-after chassis builders on the East Coast. A three-year waiting list and a portfolio of work equal to none just goes to show that 20 years of doing something right doesn’t go unnoticed. Once you see this triple threat of Nissans he’s about to unveil, the modern custom truck scene may never be the same.

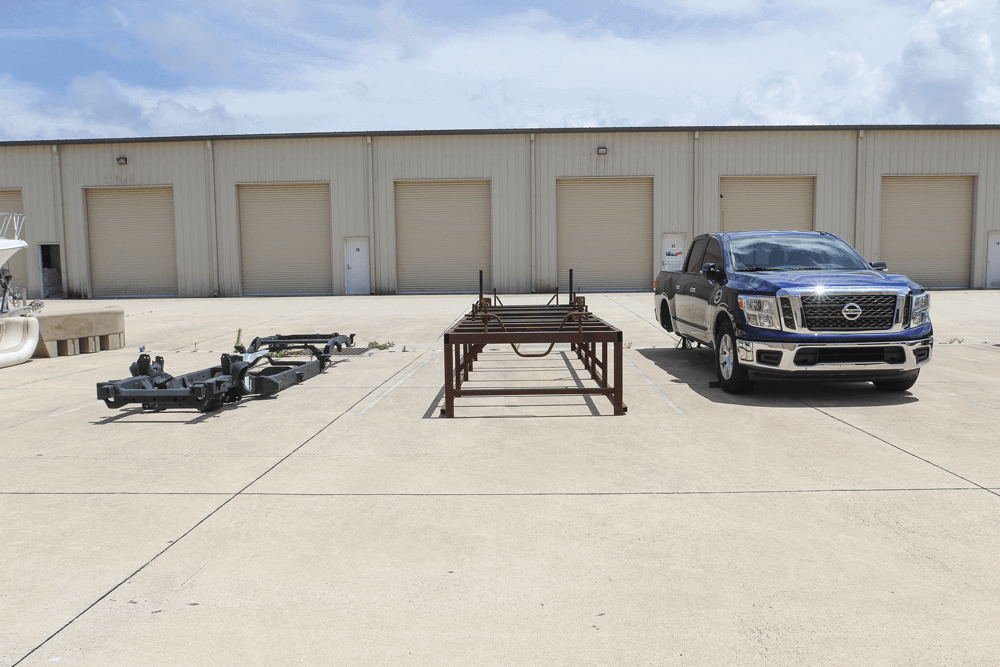

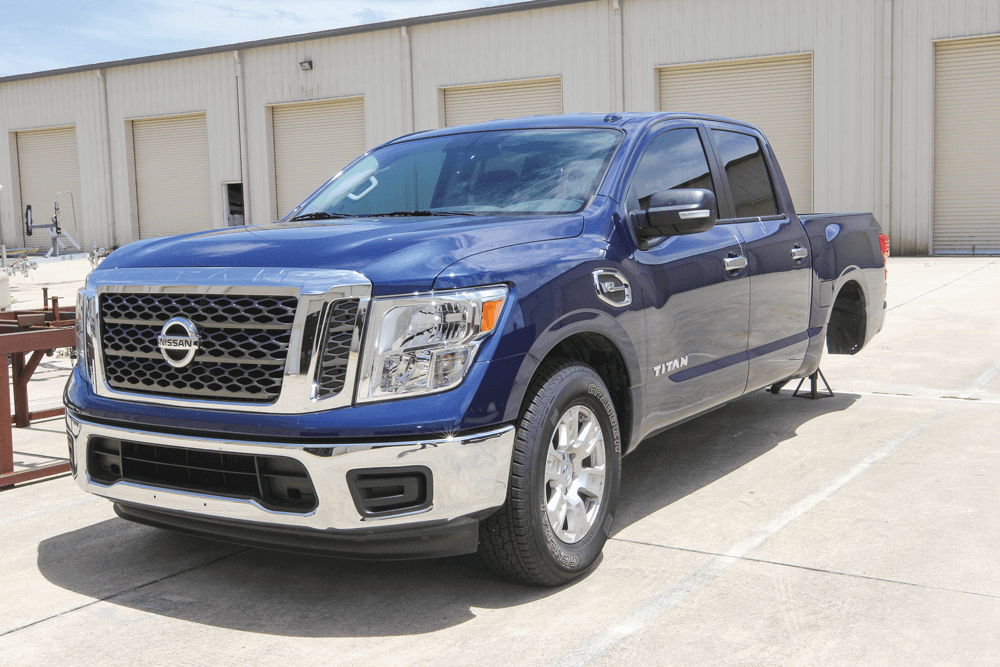

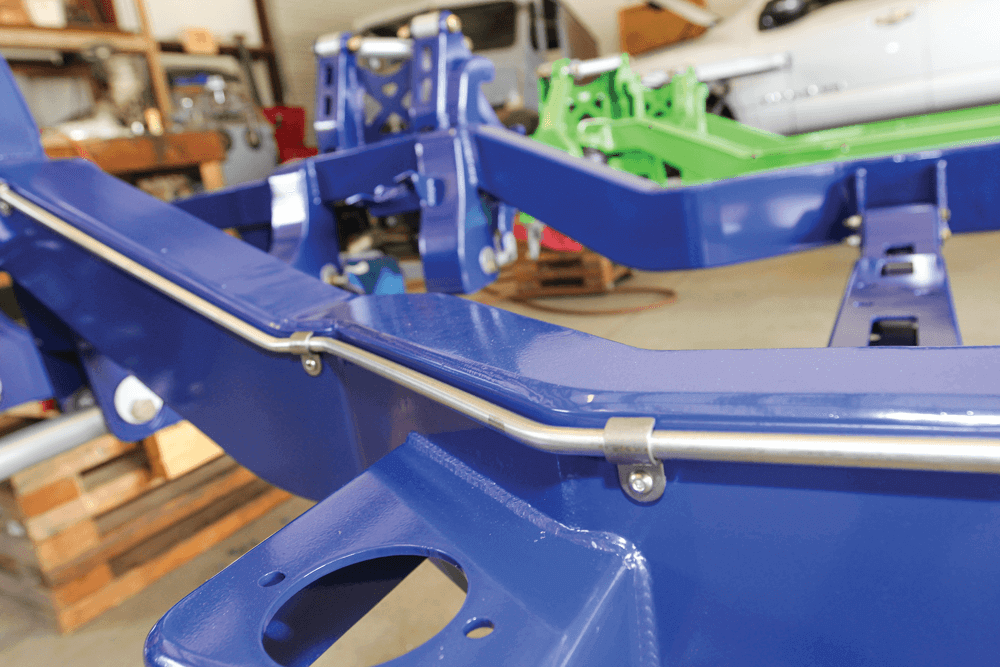

After selling his well-known four-door dually Nissan truck, Jimmy set out to build something exciting and unique. An off-the-lot Nissan Titan is his choice for a blank slate and a freshly built full-plate powder-coated chassis is the ultimate goal. A project like this is one of those builds that you know you won’t see again anytime soon, or so he originally thought.

AN OFF-THE-LOT NISSAN TITAN IS HIS CHOICE FOR A BLANK SLATE AND A FRESHLY BUILT FULL-PLATE POWDER-COATED CHASSIS IS THE ULTIMATE GOAL.”

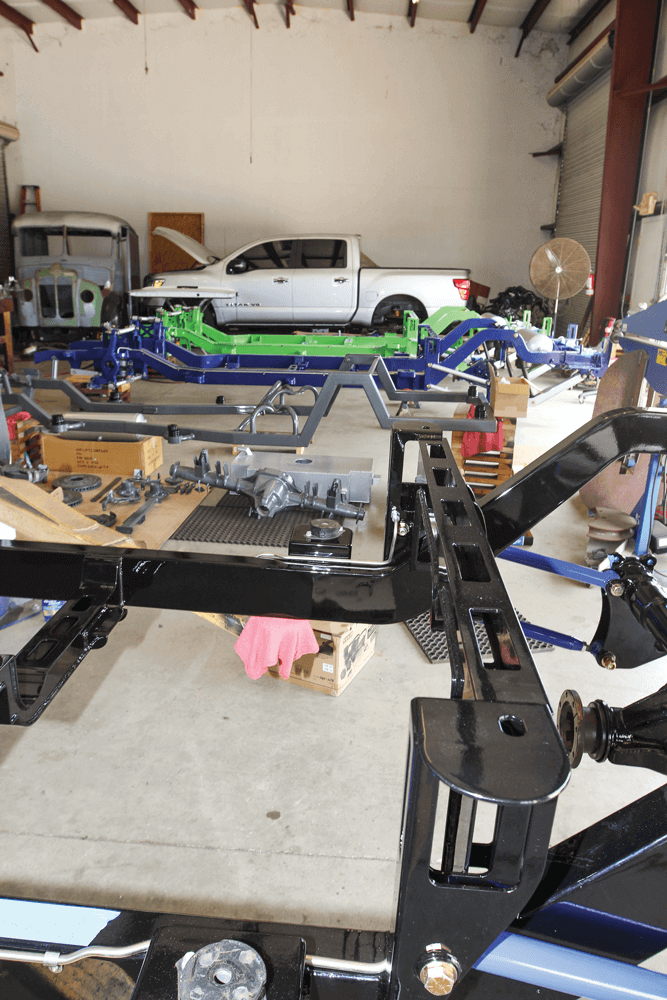

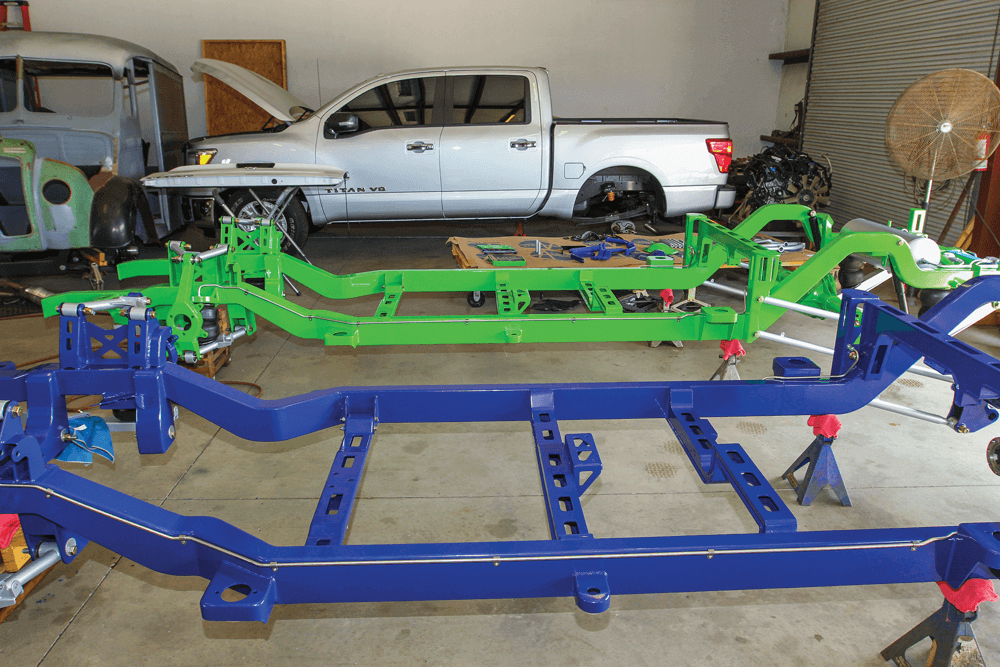

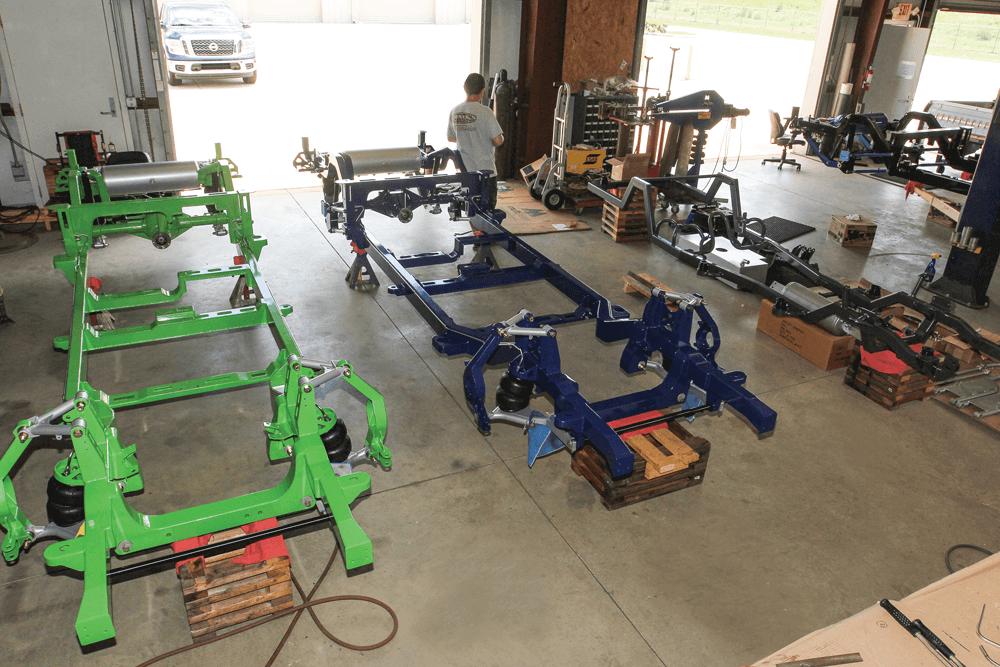

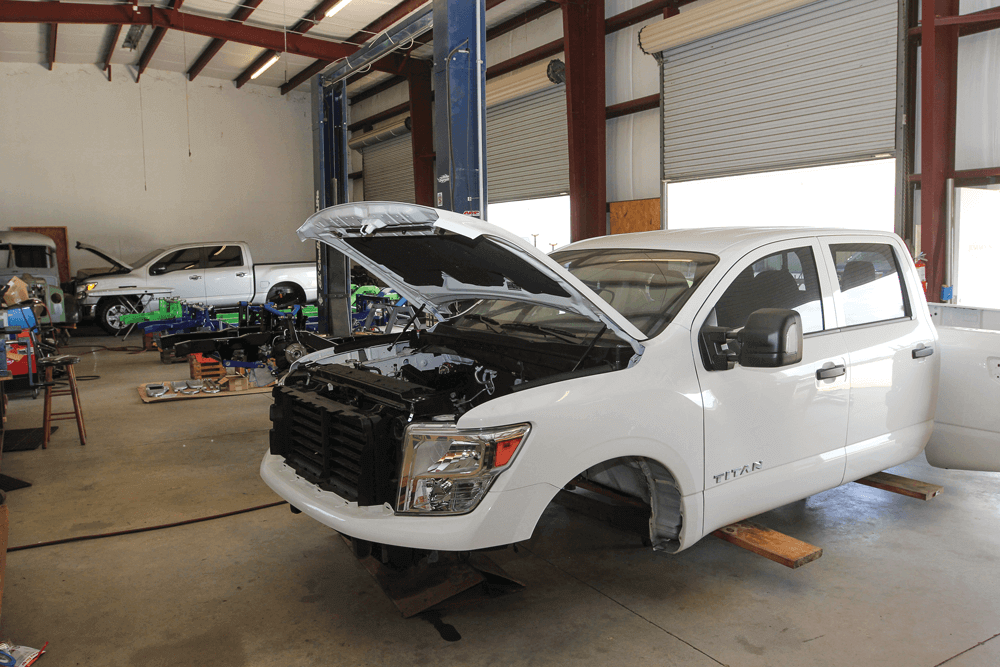

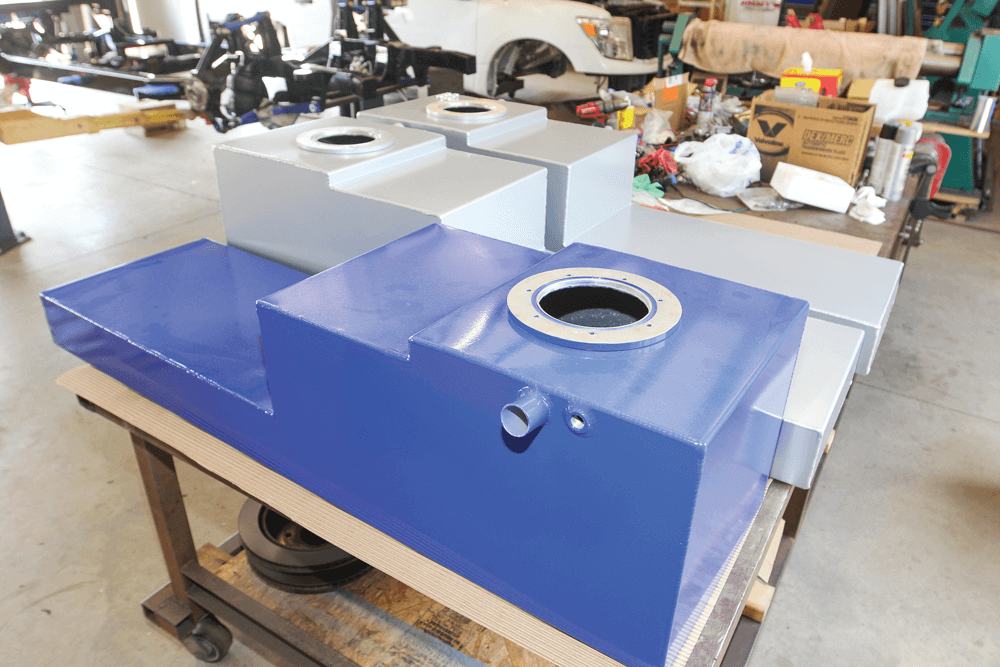

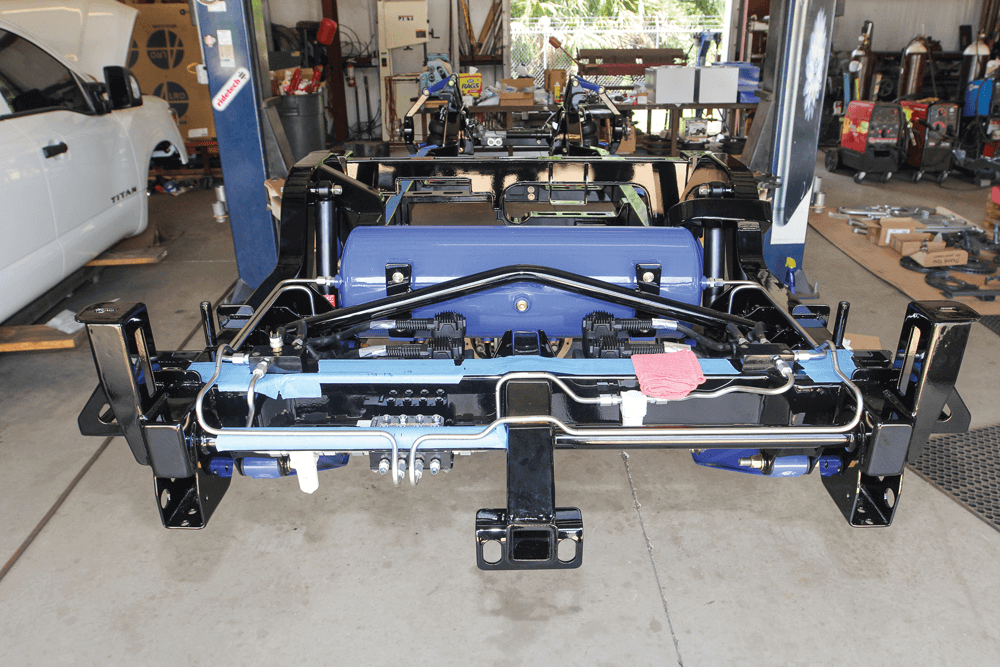

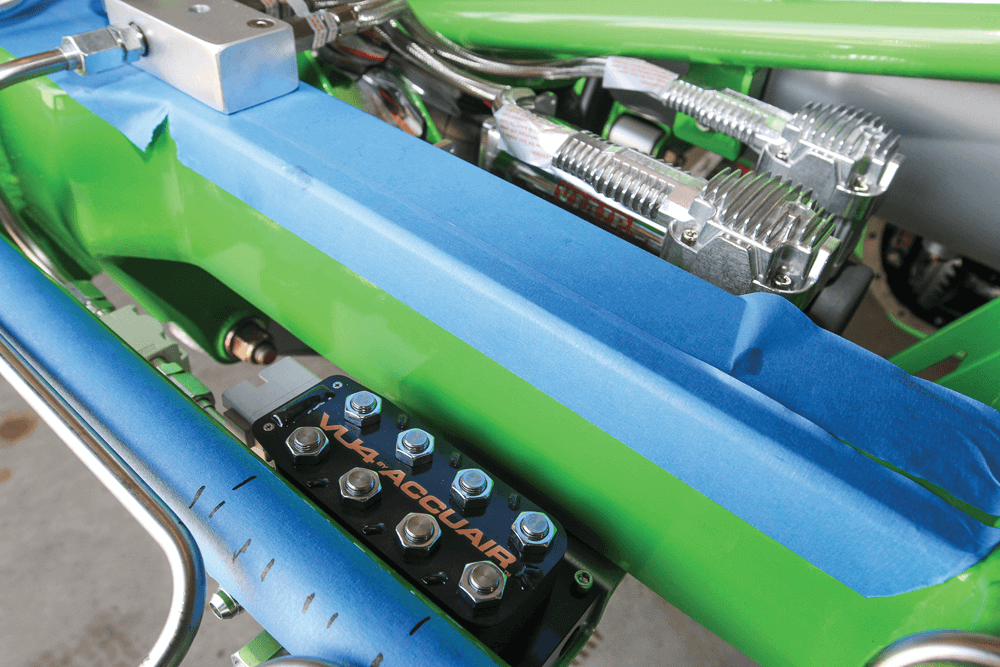

If you’re a hardcore enthusiast and stay involved with this scene, you know it’s almost impossible to keep a secret project a secret. No matter how hard you try or how few people you tell, somehow word spreads fast and people talk. Which is exactly what happened with Jimmy’s newest Nissan project, and soon after the first few bolts were removed from his Titan, he had two separate customers dropping deposits and keys to brand-new Titans of their own. Three identical builds at once is a challenge for even the largest custom truck and street rod shops across the country, but that didn’t stop Jimmy from accepting the challenge, with the only help coming from his extremely capable assistant. All three trucks have full-plate, powder-coated frames that sit flat on the ground, along with built-in battery boxes and mounting locations for the electronic-ride-controlled AccuAir suspension. Each and every component of the chassis and suspension was fabricated in-house, including the fuel cells, control arms and even the knuckles.

All three trucks are due to hit the street within the month, and we will certainly be there to document their first ride. Keep an eye on future issues for our feature on these three Titans and probably anything else that comes out of these bay doors.

Share Link