Joe Greeves

.

September 19, 2025

.

Features

.

Joe Greeves

Joe Greeves

.

September 19, 2025

.

Features

.

Joe Greeves

WE are always interested in the creation process behind the custom trucks we feature. We learned that building a feature vehicle is invariably a team effort, with the owner providing either talent or direction, then often relying on industry specialists for specific skills. Assembling a modern chassis, selecting a modern powertrain, and wrapping the package with classic sheetmetal means the finished product will have vintage looks and gratifying road manners. Who doesn’t like a trophy winner that can comfortably cruise the interstates?

From Port Orange, Florida, Tom Taxon is a retired mechanical engineer and an avid enthusiast who understands these modern, feature-building concepts very well. Over the years, he’s had a collection of interesting customs, and it was time for something new. A shiny red 1949 Chevy 3100 pickup caught his eye at a local show. That’s when Tom decided to tailor one of his own. Chevrolet got it right when they designed this era truck, and its popularity has been on a continuous upswing for decades. While some builders seek flashy outcomes, Tom’s plan would opt for a conservative approach that enhanced the original classic lines without disturbing the truck’s iconic profile.

As you might expect, a mechanical engineer approaches things carefully, laying out a step-by-step plan. The multiyear process began with acquiring parts for Tom’s one-of-a-kind classic Bowtie. By default, sheetmetal acquisitions had to be a blend of new old stock, remanufactured parts, and custom-fabbed items—all carefully stored until it was time to install. The chassis, however, was a different story. From the outset, he decided that new stuff was way better than modifying old stuff. Aftermarket upgrades would create a robust suspension with direct, close-ratio steering, flat cornering, and amazing braking. These are qualities you don’t associate with 75-year-old technology.

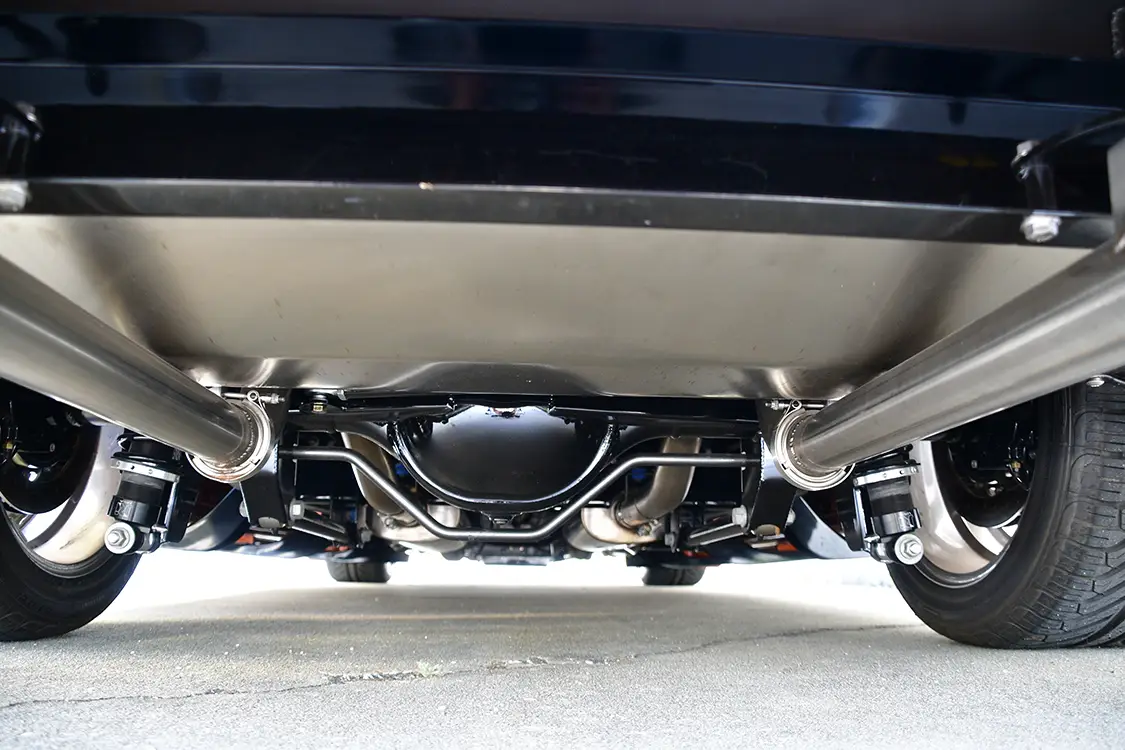

Thankfully, Art Morrison Enterprises had exactly the package Tom was looking for. The 1947-1953 Chevrolet GT Sport chassis would give him modern handling and allow him to easily bolt on vintage Chevrolet sheetmetal. Tom added multiple options, like the Wilwood brake package that included 13-inch drilled and slotted rotors. AME also supplied coilovers and sway bars, along with a 4-link rear that holds a new 9-inch Ford POSI. Tom also chose a 17-gallon gas tank from Rick’s Tanks since it was designed to work with the AME chassis. The chassis became a roller thanks to classic 18-inch American Racing Torq Thrust II wheels and Michelin Pilot Sport rubber.

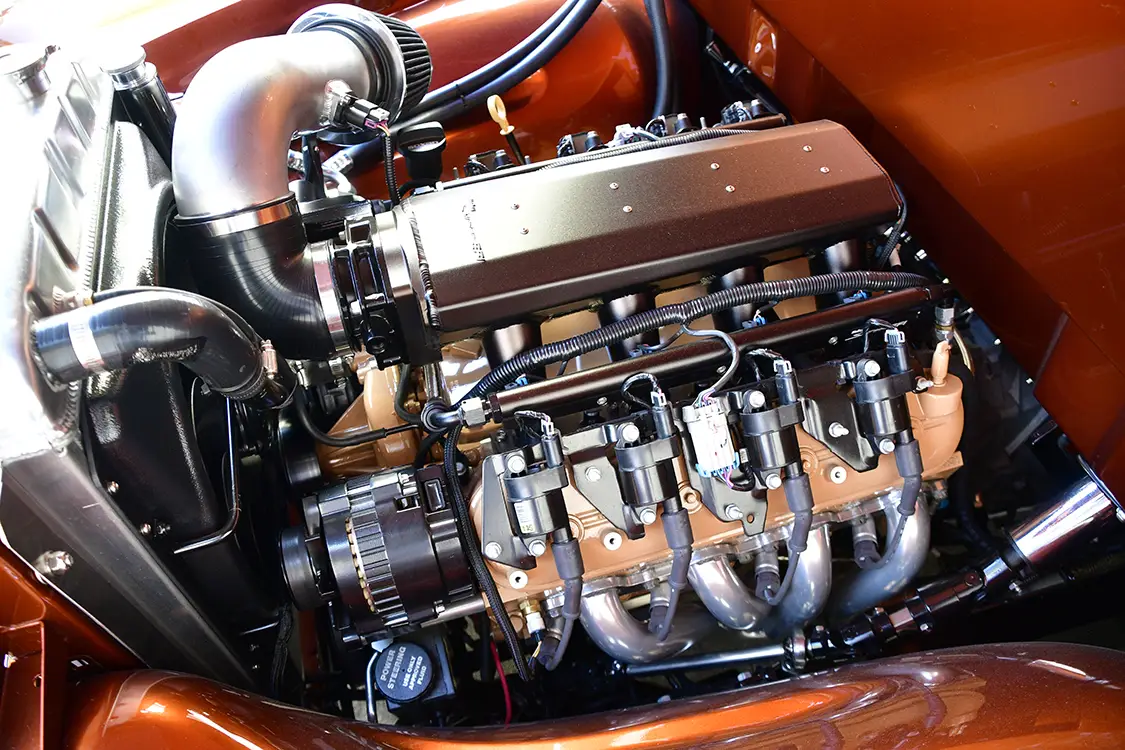

Once chassis mods were complete, it was the perfect time to install the power plant. The new, high-performance Chevrolet LS376-480 crate motor was the same engine in Tom’s current ‘56 Oldsmobile—a naturally aspirated, factory-built V-8 capable of blurring the scenery at an alarming rate. Additions began with the black Pro-Track serpentine system from March Performance that activated the LS alternator, AC, and power steering. A Holley Sniper EFI manifold handled intake, while AME custom headers expedited exhaust. Tom created the 2 1/2-inch stainless steel MagnaFlow system, incorporating a pair of electric cutouts to alert the neighbors when he’s in town! A Chevrolet 6L80-E trans was strong enough to handle the mega motor. While thundering down the drag strip and bouncing off the rev limiter was never part of the plan, the 500hp double-shot-of-espresso motor does allow the occasional roasting of the Michelins. Leaving signature stripes on the asphalt needs just a brief stab at the long, skinny pedal.

The collection of body parts became a blend of a few old parts from the original Chevy along with mostly new items from Premier Street Rods in Arizona, Ecklers Chevrolet in Florida, and other suppliers. Once everything was on hand, the first step was lowering the cab in place. The firewall was trimmed for the big V-8, and a new tunnel was fabricated for the transmission.

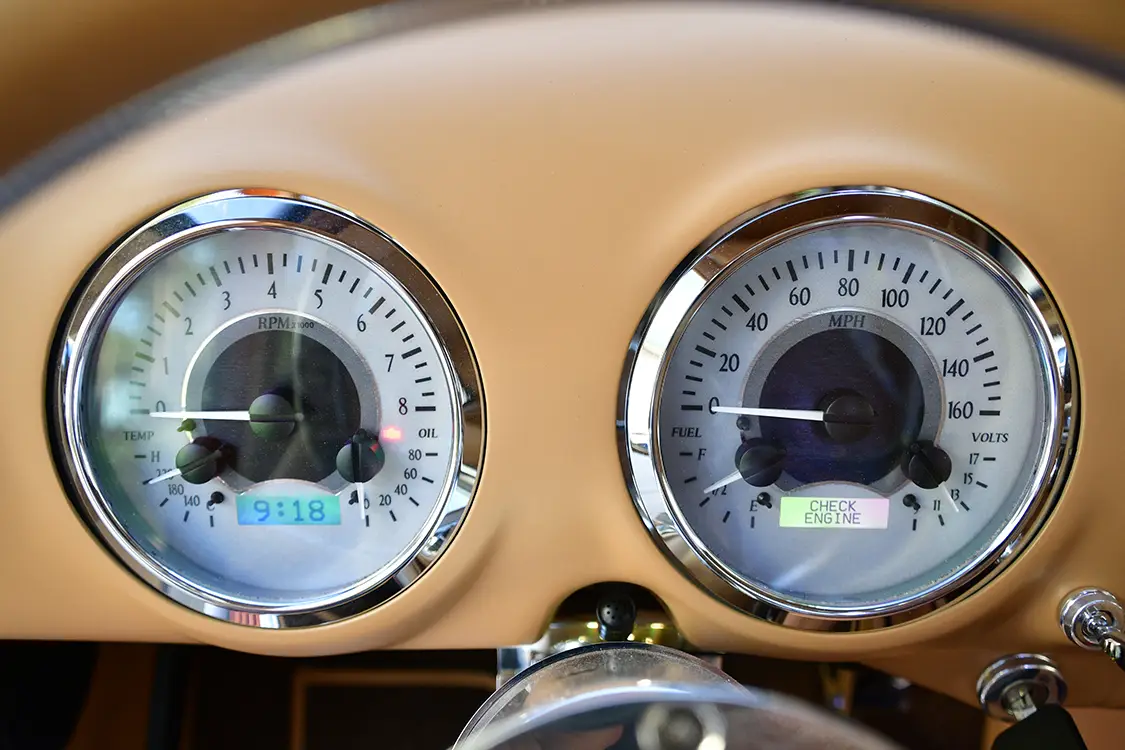

Transitioning to the interior, Tom began a significant rework of the dash, beginning with Dakota Digital VHX instruments and Dakota Digital cruise control. The glove box was welded shut, AC vents were cut into the middle and end of the dash, and a double-DIN JVC multimedia receiver was installed. The 6.75-inch touchscreen incorporates gesture control, a 13-band graphic equalizer, and delivers a combination of music, rearview camera, GPS, and more. Comfort was next on the list. Sourced from a 2019 Nissan, the plush buckets were shortened to stay below the back window and hinged to allow access to the ECM and Ron Francis fuse panel under the seats. After fabricating inside panels for the doors and other parts of the cab, Tom contacted Del Lyons, owner of The Upholstery Man shop in South Daytona, who stitched the double diamond spice-colored interior. Tom installed his own one-piece Classic Parts headliner. The result is an elegant interior that is comfortably plush and tech-heavy without being gaudy.

The bed was next, and Mar-K Manufacturing had the perfect set of bedsides, tailgate, and front panel that greatly simplified the building process. Personal touches included Dan Carpenter wheel tubs and a Smokey Road Rod Shop laminated aluminum floor. For a little humor, a set of 1939 Lincoln taillights were integrated into the end of the bedsides. This addition is humorous because Tom has Chevy motors in his two Fords. He smiles at the Lincoln lights, saying, “I needed a little Ford stuff in my Chevy!” The front end was modernized with a fiberglass roll pan from Brothers Truck and a steel pan for the rear. Wrapping up the outside upgrades, the doors received special treatment with power windows and Kindig It recessed door handles.

Although the truck is complete and already a trophy winner, Tom enjoys the fact that there are always more subtle upgrades that can be added over time…

Here’s where the efforts in his home garage took a different turn. The front end, hood, fenders, inner fenders, grille, headlights, and front roll pan were a different sort of challenge, so Tom decided professional help was the best solution. “After too many attempts to get any kind of decent fit between fenders, hood, and body, I finally decided that half of being smart is knowing where you’re dumb. Sometimes it’s best to let the experts do it right.” Tom turned to Jeff’s Restorations in Holly Hill, Florida, for the finishing touches. Dave Clark was the point man on the project, dealing with doors, hood, fender fitments, Hagan recessed headlights, and the reversed Chevrolet logo on the tailgate. The multiyear build wrapped up with the final color applied by Jeff’s Restorations. No wild, inappropriate graphics here. The classic single shade of PPG Vibrance Nutmeg paint was the stunning conclusion and the perfect finishing touch.

Although the truck is complete and already a trophy winner, Tom enjoys the fact that there are always more subtle upgrades that can be added over time, making his brand-new, old Chevy a rolling work of performance art. It was fun to build, it is currently fun to drive, and the possibility for additional sophisticated additions will continue to make it fun in the future.

ENGINE & DRIVETRAIN

CHASSIS & SUSPENSION

WHEELS & TIRES

BODY & PAINT

INTERIOR

Share Link