Chris Hamilton

.

May 31, 2022

.

c10

.

Chris Hamilton

.

May 31, 2022

.

c10

.

Relating a classic truck build to an iconic movie title is a great way to get people to remember your project and point it out at the local truck shows. The concept behind project Rocky was to find an old, retired workhorse of a truck, tear it all the way down to its core, and completely rebuild it into an all new, better version of its original self.

Rocky Balboa is a well-known character in classic cinema, and his story equally relates to the tale we are telling: retired, reborn and eventually re-reigning as the king with the crown, or in this case championship belt. That’s the plan for project Rocky, although I bet we’re going in a different direction than you would expect.

This truck came from the factory in 2WD and we plan to keep it that way since it’s a street truck only. We are not towing anything, and we’re not going off road. We’re simply ripping it around the streets and enjoying a cool, fun, modernized classic truck.

To clear our 22×12 American Force wheels, we will need a bit of a lift kit installed on this truck, but not too tall. We only need to clear a 33-inch-tall Toyo tire, but the width of the wheel will require a tad more height upfront. The best way to get some extra inches out of the front of a classic 2WD truck is to simply replace the spindles. Unfortunately, no one makes lift spindles for a ’73-’87 2WD Squarebody truck. So we had to improvise and use a Rough Country 4-inch lift spindle for an ’88-’98 C1500. The upper and lower control arm ball joints will also have to be swapped to match the spindles.

This is just the beginning of what is expected to be an exciting build. Keep up to date by following us online via social media, and subscribing to both Street Trucks and C10 Builder’s Guide. This will be one of those trucks you want to ride in, and if you see us at a truck show, hop in the passenger seat and let’s go!

Also you can watch Project Rockey Part 2 –

Achieving a seamless fit between your lift kit components and your truck requires meticulous planning and understanding of various factors. Here’s a detailed guide to help you ensure everything works harmoniously:

Before purchasing any components, take note of your truck’s make, model, year, and existing modifications. This baseline understanding is crucial for selecting compatible parts.

Select a lift height that aligns with your driving needs and tire size preferences. For instance:

The interplay between springs and shocks is vital for ride quality and articulation:

With larger tires, space in the wheel well is limited. Be prepared for potential fender trimming to prevent tire rubbing, especially during articulation. This step is often necessary even with high-quality springs if you aim to maximize tire size.

Lifts alter the geometry of your steering system. Ensure compatibility by:

Beyond the core components, additional modifications might be necessary:

Allocating your budget wisely ensures better compatibility and safety:

Ensuring compatibility of lift kit components with your truck is a complex but manageable task. By carefully considering your truck’s specifications, selecting the right lift height, and choosing compatible springs and shocks, you can achieve a balanced and functional lifted setup. Remember to factor in potential fender trimming and additional modifications to truly maximize your truck’s performance and aesthetics.

When considering aftermarket springs for a vehicle lift, it’s crucial to understand the potential drawbacks. Here are some issues associated with using Rough Country springs:

In summary, when opting for these springs, weigh the balance between their affordability and the potential need for further modifications to ensure a satisfactory driving experience.

When you lift a vehicle, the front sway bar is directly impacted, which can lead to decreased stability and handling issues. The altered angle places additional stress on the sway bar, potentially causing poor performance during turns and uneven terrain navigation. Here’s how you can mitigate these issues:

By implementing these measures, you can effectively mitigate the impact of lifting on the front sway bar and maintain both performance and safety.

If you’re considering installing a lift kit to accommodate 35″ or 37″ all-terrain tires, you’ll find numerous YouTube tutorials to help guide you through the process. Also you can watch project rocky part 1 and part 2 for the best tutorials. Here are some tips on finding the best ones:

Remember, installing a lift kit can be complex and might also tie into other jobs, like replacing your steering gearbox. Make sure the tutorial addresses any interconnected tasks to ensure a smooth installation process.

To clear our 22×12 American Force wheels, we will need a bit of a lift kit installed on this truck, but not too tall. We only need to clear a 33-inch-tall Toyo tire, but the width of the wheel will require a tad more height upfront. The best way to get some extra inches out of the front of a classic 2WD truck is to simply replace the spindles.

Unfortunately, no one makes lift spindles for a ’73-’87 2WD Squarebody truck. So we had to improvise and use a Rough Country 4-inch lift spindle for an ’88-’98 C1500. The upper and lower control arm ball joints will also have to be swapped to match the spindles.

When installing a lift kit, several additional parts and modifications might be necessary to ensure the job is done right and the truck performs optimally:

Both options allow you to maintain flexibility. If you change your mind later, you can still swap out the factory pack for something softer.

The parts for these upgrades can add up to $400-$500 if you go for quality components. This includes:

These modifications, while adding to the initial cost, will ensure a smoother ride and better handling. They also provide the flexibility to make future adjustments as your needs evolve.

To clear our 22×12 American Force wheels, we will need a bit of a lift kit installed on this truck, but not too tall. We only need to clear a 33-inch-tall Toyo tire, but the width of the wheel will require a tad more height upfront. The best way to get some extra inches out of the front of a classic 2WD truck is to simply replace the spindles.

Unfortunately, no one makes lift spindles for a ’73-’87 2WD Squarebody truck. So we had to improvise and use a Rough Country 4-inch lift spindle for an ’88-’98 C1500. The upper and lower control arm ball joints will also have to be swapped to match the spindles.

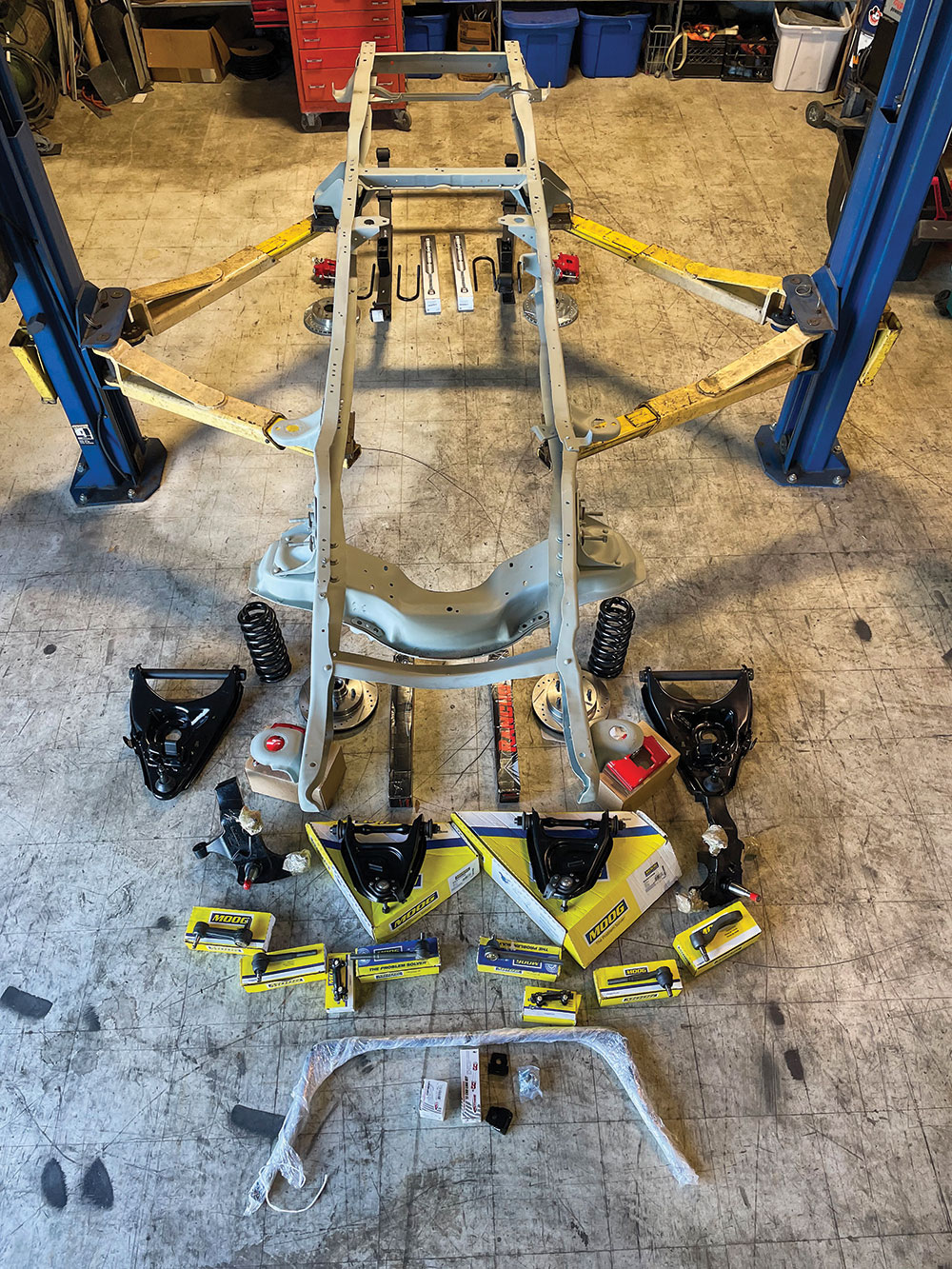

Now that the body is removed, we can start on the frame rails. With the factory suspension removed, we brought it over to the sandblaster to clean all the metal.

The first new part from Rock Auto are the upper control arms. These are factory original for ’79 Chevy C10 HD trucks with ’88-’98 TTX ball joints from Mevotech. The lower control arms are also from a ’79 ChevyC10 HD truck with ’88-’98 ball joints. The trick to the lift is this 4-inch lift spindle for ’88-’98 Chevy trucks. With the swapped out ball joints, everything matches up correctly.

“To clear our 22×12 American Force wheels, we will need a bit of a lift kit installed on this truck, but not too tall. We only need to clear a 33-inch-tall Toyo tire, but the width of the wheel will require a tad more height upfront.

When considering larger tires like 35″ or even 37″, different lift heights are necessary. Generally, a 4-inch lift is the minimum required for 35″ tires, especially on a 3/4 ton truck. However, if you’re driving a 1-ton truck, you might get away with a 2-3 inch lift due to the higher default clearance.

When installing a lift kit, you might need to:

If you go beyond a 4-inch lift, all these modifications become necessary.

In summary, while a moderate lift can accommodate larger tires, always consider the additional modifications and costs involved to ensure a smooth and safe ride.”

Custom front and rear springs are available, with various length options to tailor the suspension setup, enhancing performance and ride quality.

The available lift kit options include budget spring lift kits in 4″ and 6″ configurations, standard spring lift kits with customizable lift heights from 2″ to 12″, custom spring lift kits specifically crafted for lift heights between 2″ and 7″, and both front and rear coilover conversion kits with choices of Fox or King shocks.

A lifted 2wd truck will likely drive significantly differently than a stock 2wd, with a departure from the normal feel on the road. It also won’t match the driving dynamics of a properly lifted 4×4, which is designed to handle such modifications more effectively.

Lifting a 2wd truck alters the steering angles, which can compromise ride quality and safety. This change can lead to handling issues and potentially affect the overall stability of the vehicle.

To clear our 22×12 American Force wheels, we will need a bit of a lift kit installed on this truck, but not too tall. We only need to clear a 33-inch-tall Toyo tire, but the width of the wheel will require a tad more height upfront. The best way to get some extra inches out of the front of a classic 2WD truck is to simply replace the spindles.

Unfortunately, no one makes lift spindles for a ’73-’87 2WD Squarebody truck. So we had to improvise and use a Rough Country 4-inch lift spindle for an ’88-’98 C1500. The upper and lower control arm ball joints will also have to be swapped to match the spindles.

However, it’s crucial to understand the potential implications of lifting a 2WD truck.

Lifting a 2WD can alter steering angles, which might affect both ride quality and safety. These modifications can lead to major steering issues, making the handling unpredictable. This is not unlike what some Jeep owners experience when they lift their vehicles, potentially resulting in dangerous driving conditions and even accidents.

It’s important to note that a lifted 2WD truck won’t drive the same as a stock model. The handling and feel of the vehicle will change significantly. If you’re used to a conventional, smooth ride, expect the driving experience to shift to something less predictable and quite different from a properly lifted 4WD.

If the truck is a family vehicle, consider the safety of your passengers. If lifting cannot be done safely, it might be worth reconsidering the modification or even switching to a vehicle that better meets your needs, especially if children frequently ride with you.

In summary, while the technical aspects of lifting your truck can be managed with the right components, it’s essential to weigh these against the potential risks to safety and driving comfort.

To clear our 22×12 American Force wheels, we will need a bit of a lift kit installed on this truck, but not too tall. We only need to clear a 33-inch-tall Toyo tire, but the width of the wheel will require a tad more height upfront. The best way to get some extra inches out of the front of a classic 2WD truck is to simply replace the spindles.

Unfortunately, no one makes lift spindles for a ’73-’87 2WD Squarebody truck. So we had to improvise and use a Rough Country 4-inch lift spindle for an ’88-’98 C1500. The upper and lower control arm ball joints will also have to be swapped to match the spindles.

However, it’s crucial to consider the potential steering issues that may arise from this modification. Lifting a truck can alter the steering angles significantly, leading to unpredictable handling and compromising ride quality and safety.

By keeping these considerations in mind, you can enjoy the aesthetic and functional benefits of a lift while ensuring your truck remains safe to drive.

If lifting the truck cannot be done safely, one alternative is to consider selling the vehicle and opting for a 4×4 model, especially if safety for passengers, like children, is a priority.

Yes, lifting a truck can lead to significant steering issues that may pose a danger. These modifications can make the steering unpredictable, increasing the risk of accidents.

To clear our 22×12 American Force wheels, we will need a bit of a lift kit installed on this truck, but not too tall. We only need to clear a 33-inch-tall Toyo tire, but the width of the wheel will require a tad more height upfront. The best way to get some extra inches out of the front of a classic 2WD truck is to simply replace the spindles.

Unfortunately, no one makes lift spindles for a ’73-’87 2WD Squarebody truck. So we had to improvise and use a Rough Country 4-inch lift spindle for an ’88-’98 C1500. The upper and lower control arm ball joints will also have to be swapped to match the spindles.

When it comes to lifting a 2WD C10, there are several alternative methods you can consider to achieve the desired height. Here’s a closer look at some options:

Each method comes with its own set of considerations, from cost to safety implications. Whether you’re modifying your truck for larger wheels or simply seeking a more aggressive stance, weighing these options is key to making an informed decision.

You can lift a 2WD vehicle using body lift kits or coil spring spacers, typically available in 2-3 inch sizes.

Factors to Consider

Generally, the more expensive the lift kit, the better the quality. Investing in a high-quality kit can save you money in the long run by reducing wear and tear on your vehicle. However, consider your budget constraints. Are you looking for the cheapest option, or is quality your top priority?

Older truck models, like certain Chevy 1/2 tons and 3/4 tons, may have unique issues, such as frames cracking at the steering box, especially with larger tires. It’s essential to examine whether a steering box brace—either bolt-in or weld-in—might be necessary for your model to maintain structural integrity.

For those planning to use 35-inch tires, a minimum of 4 inches of lift is recommended for most vehicles. In some cases, heavier-duty vehicles may require only a 3-inch lift due to their higher starting stance. Consider whether your truck still needs load carrying capacity and how that might affect your lift height decision.

Specific spring types can dramatically affect your ride:

After lifting, the front sway bar might get tilted, often making the ride harsh. You might want to remove the sway bar completely as a trial, or consider a quick disconnect kit for more flexibility.

Define the type of off-roading you plan to do. Is it just gravel roads and washboard, or are you tackling more challenging off-road trails? Your off-roading style will significantly influence the type of lift kit you choose.

Experience varies, so consulting someone with extensive off-roading experience can provide invaluable insights tailored to your specific needs. Seeking advice from knowledgeable sources can help you understand the nuances of each lift option and make an informed decision.

By evaluating these factors, you can select a lift kit that enhances your vehicle’s performance, ensuring a safer and more enjoyable off-roading experience.

When considering how lifting a truck affects its ride quality, especially on highways, several factors come into play. Lifting a truck can significantly alter its handling dynamics and ride comfort. Here’s what you need to know:

Specific spring types can dramatically affect your ride:

A lifted c10 truck can ride harder on highways, making long-distance driving less comfortable. This is particularly true if you opt for a lift that doesn’t prioritize highway stability. Adding a significant lift, such as a 4″, might make your truck feel more rigid and less forgiving on uneven pavement.

However, there’s more to consider. If you’re worried about highway performance, you might think about enhancing the transmission. Upgrading from a three-speed to a four-speed transmission can introduce an overdrive gear, potentially increasing gas mileage and making highway cruising more efficient. This tweak can make a lifted truck more viable for longer journeys.

Ultimately, the key is balancing your off-road aspirations with on-road comfort. By carefully selecting the right components and considering additional modifications like transmission upgrades, you can enjoy both rugged adventures and smooth highway rides.

A 4″ lift could potentially make highway driving less enjoyable due to changes in ride dynamics, but this depends on the specifics of the lift and personal preferences.

When installing a lift kit, several additional parts and modifications might be necessary to ensure the job is done right and the truck performs optimally. Beyond the basic components, there are several considerations to keep in mind:

Both options allow you to maintain flexibility. If you change your mind later, you can still swap out the factory pack for something softer.

The parts for these upgrades can add up to $400-$500 if you go for quality components. This includes:

These modifications, while adding to the initial cost, will ensure a smoother ride and better handling. They also provide the flexibility to make future adjustments as your needs evolve. It’s important to assess your specific requirements, such as the truck’s load capacity and off-roading needs, to choose the best components and solutions.

Larger tires can lead to frame cracking at the steering box, an issue that can affect even heavier-duty models. Installing a steering box brace can help prevent these problems, providing additional support and stability.

Factors to Consider

Generally, the more expensive the lift kit, the better the quality. Investing in a high-quality kit can save you money in the long run by reducing wear and tear on your vehicle. However, it’s essential to keep a firm grip on your credit card, as some premium options can quickly escalate in price.

For those considering 35-inch tires, a minimum lift of 4 inches is recommended in the front. Vehicles like the 3500, which sit slightly higher than others, might manage with a 3-inch lift. If you’re aiming for a significant lift, crossover steering becomes crucial to ensure stability and handling remain intact.

By combining cost considerations with detailed performance insights, you can make an informed decision that balances your budget with your off-roading needs.

For lifts exceeding 4 inches, crossover steering is advised for improved handling and stability. A drop Pitman arm is preferred over a drop drag link for more precise steering control.

If you’re considering upgrading your 2WD truck’s stance, there’s a healthy debate about choosing between a leveling kit and a full body lift. Here’s a breakdown of the opinions on each option:

Ultimately, the decision hinges on personal preference and intended use. If utility and modest enhancement are your goals, a leveling kit might suit you best. However, if you’re aiming for a more imposing look and have a penchant for customizations, a full body lift could be worth considering.

Lifting a 2WD truck often sparks debate among truck enthusiasts. One common misconception is that it’s merely “posing” or pretending to be something it’s not. This perception, however, overlooks several key points and motivations behind why people choose to lift their 2WD trucks.

Many assume that lifting a 2WD truck is solely for aesthetic reasons. While enhancing the appearance is a popular motivation, it’s not the only one. Improved ground clearance for off-road driving, better visibility, and a personal preference for a taller stance are also valid reasons.

Some believe only 4WD trucks gain from a lift. This is far from the truth. A 2WD lift offers unique advantages, such as making certain terrain more manageable and enhancing the truck’s presence. Many find these benefits appealing regardless of off-road capability.

There’s a notion that lifting a 2WD truck inherently reduces its efficiency or drivability. However, with the right choices of suspension kits from reputable brands, a lift can maintain—and sometimes even enhance—performance on various terrains.

In conclusion, lifting a 2WD truck is not merely about pretending to be a 4WD. It’s about personal choice, functionality, and aesthetic value. Embracing these aspects can clear up misconceptions and appreciation for diverse truck modding preferences.

Yes, lifting 2WD trucks for aesthetic reasons is indeed a common practice among truck enthusiasts. Many people choose to enhance the visual appeal of their trucks by giving them a lift, even if they aren’t planning to go off-road.

There is a perception that most lifted trucks, regardless of whether they are 2WD or 4WD, are more about style than utility. Terms like “mall crawlers” are often used to describe lifted trucks that primarily stay on paved roads. Yet, enthusiasts argue that a 2WD performance vehicle with the right lift can turn heads and garner admiration.

Truck enthusiasts are often divided. Some believe lifting a 2WD is just for show, missing the off-road capability a 4×4 provides. Others, however, embrace the aesthetic component, insisting that a lifted truck—whether 2WD or 4WD—enhances the vehicle’s overall appearance.

In summary, while practical benefits exist, the predominant reason for lifting a 2WD truck often circles back to visual impact and personal expression. And for many, that reason alone is more than enough.

Regardless of steering components, the type of lift springs used can affect ride quality. Some lift spring brands are known for a very stiff ride, so be sure to choose springs that provide a balance between height and comfort according to your preference.

When lifting your truck, maintaining load carrying capacity is crucial, especially if you frequently transport heavy items. For those who work with robust equipment, like woodworking machinery that can weigh upwards of 2000 pounds, it’s essential to ensure your truck’s suspension can handle the weight without compromise.

When lifting a 2WD truck, specific considerations must be taken to maintain mechanical integrity. Ball joints and tie rods should not be overstressed, as they are critical for ensuring safe and effective steering. Check that these components have plenty of threads remaining to allow for proper steering adjustments. This attention to detail helps avoid undue stress that can lead to premature wear.

Lifting also offers benefits such as increased ground clearance and suspension travel, which can improve the truck’s overall versatility. Depending on the lift kit chosen, handling might also see improvements, enhancing both performance and safety.

By carefully selecting your suspension components and considering additional support systems, you can achieve a lifted c10 truck that meets both your height and load carrying requirements, while ensuring mechanical integrity and optimal performance.

After lifting a truck, it’s important to perform checks on mechanical components such as ball joints and tie rods. Ensuring these parts are not overstressed is vital to maintaining the vehicle’s mechanical integrity and safety.

Lifting a 2WD truck offers several advantages, including increased ground clearance, which can enhance off-road capabilities. It may also improve the vehicle’s handling and travel, depending on the modifications and components used.

When lifting a 2WD truck, it’s crucial to ensure that components like ball joints and tie rods are not overstressed. Proper alignment and adequate threading are necessary to maintain effective steering and avoid undue stress on these parts.

When considering the differences between lifted 2WD and 4WD trucks, it’s important to weigh both functionality and aesthetics. Lifting a 2WD truck primarily enhances its appearance, giving it a more rugged, elevated look, and provides some additional ground clearance. This can be particularly appealing for those who prioritize style and a commanding road presence.

In terms of functionality, a 2WD lift might not offer the same off-road capabilities as a 4WD truck. If your primary needs are related to towing capacity and highway driving, a lifted 2WD truck can serve you well. Many owners appreciate the ability to customize their trucks with larger tires and unique wheel designs, adding a personal touch to their vehicle’s aesthetic without necessarily enhancing off-road performance.

However, if off-road adventures or challenging terrains are your focus, a 4WD truck is typically better suited for these environments. The lift on a 4WD truck enhances its inherent ability to tackle rugged landscapes, which a 2WD lift might not fully replicate.

By keeping these considerations in mind, you can enjoy the aesthetic and functional benefits of a lift while ensuring your truck remains safe to drive. Whether you opt for a 2WD or 4WD, understanding your priorities will help guide your decision, ensuring that your truck meets your specific needs and style preferences.

Common modifications include choosing larger tires and possibly altering wheel sizes to complement the lift. These changes enhance the truck’s aesthetic appeal and improve its stance on the road.

Some people feel that lifting a 2WD truck might be perceived as attempting to imitate a 4WD, which can be seen as inauthentic. However, many truck enthusiasts still choose to lift their 2WD vehicles for personal aesthetic preferences.

Lifting a 2WD truck often serves to enhance its appearance and provide additional ground clearance. While it doesn’t match the off-road capabilities of a 4WD, the lift can give the truck a more robust look and handle modest terrain better.

While it is technically feasible to lift a 2WD truck, it might not be the safest choice. Altering the steering angles can negatively impact both ride quality and safety.

Additionally, there are practical considerations to keep in mind. For instance, if you live in an area prone to snow or off-road conditions, a lifted 2WD truck may not perform as expected. The lack of 4WD capability could leave you stuck in just a few inches of snow, leading to an awkward situation where you have to explain to your rescuer that your truck merely “looks” like a 4×4.

Moreover, consider the social perceptions and credibility factors. Many lifted trucks are expected to be 4WD, so having a 2WD truck with a lift might raise eyebrows among peers who are familiar with off-road performance capabilities.

In summary, while a lift might enhance the appearance of your 2WD truck, it’s crucial to weigh these potential drawbacks before making a decision.

A key practical issue is the risk of getting stuck in challenging conditions like snow, as the lift might give a false impression of enhanced capability without the actual performance benefits of a 4WD system.

Lifting a 2WD truck can lead to awkward situations if others assume it has off-road capabilities typical of a 4WD, potentially leading to embarrassment when explaining it’s purely for aesthetics.

“When it comes to modifying a vehicle’s lift and ride quality, choosing the right combination of springs and shocks is crucial. Different combinations can significantly impact both the height of your lift and the overall comfort and handling of your ride.”

But beyond the technicalities, the decision to lift a 2WD truck often comes down to personal preference. Many enthusiasts choose to lift their trucks primarily for aesthetic reasons. The enhanced look of a lifted truck can be a strong motivator, transforming a standard vehicle into something that stands out on the road.

Ultimately, the choice to lift a 2WD truck is as much about personal expression as it is about performance. It’s about creating a vehicle that not only meets technical specifications but also resonates with the owner’s unique tastes and preferences.

Share Link