John Mata Jr.

.

June 27, 2022

.

America

.

John Mata Jr.

.

June 27, 2022

.

America

.

You may be familiar with Kevin Tetz’s name, but if it doesn’t ring a bell, you’d more than likely recognize his face or the sound of his voice. Kevin has hosted and been a guest on many automotive how-to shows on regular TV, digital TV, YouTube, podcasts, as well as other social media outlets. His current show, Hands-On Cars, further shares his knowledge of everything related to building custom cars and trucks. This dude makes the rounds and has done a fine job throughout the years of sharing his expansive know-how with an audience of DIY-minded enthusiasts who are always looking to learn something new in the garage.

You may be familiar with Kevin Tetz’s name, but if it doesn’t ring a bell, you’d more than likely recognize his face or the sound of his voice. Kevin has hosted and been a guest on many automotive how-to shows on regular TV, digital TV, YouTube, podcasts, as well as other social media outlets. His current show, Hands-On Cars, further shares his knowledge of everything related to building custom cars and trucks. This dude makes the rounds and has done a fine job throughout the years of sharing his expansive know-how with an audience of DIY-minded enthusiasts who are always looking to learn something new in the garage.

Kevin always his hands working on auto projects that are mostly performance-based since that’s just what he enjoys the most. When he locked down a ’67 Chevy C10 pickup, the first thing that raced into his head was to turn it into a Pro Touring truck that would absolutely tear it up at any autocross course. While that picture might sound like a blast, it really isn’t exactly groundbreaking by any stretch—that is, until you hear Kevin’s entire plan. What he had cooking would attract more attention than that and would really be a large first step in the performance-centric C10 industry.

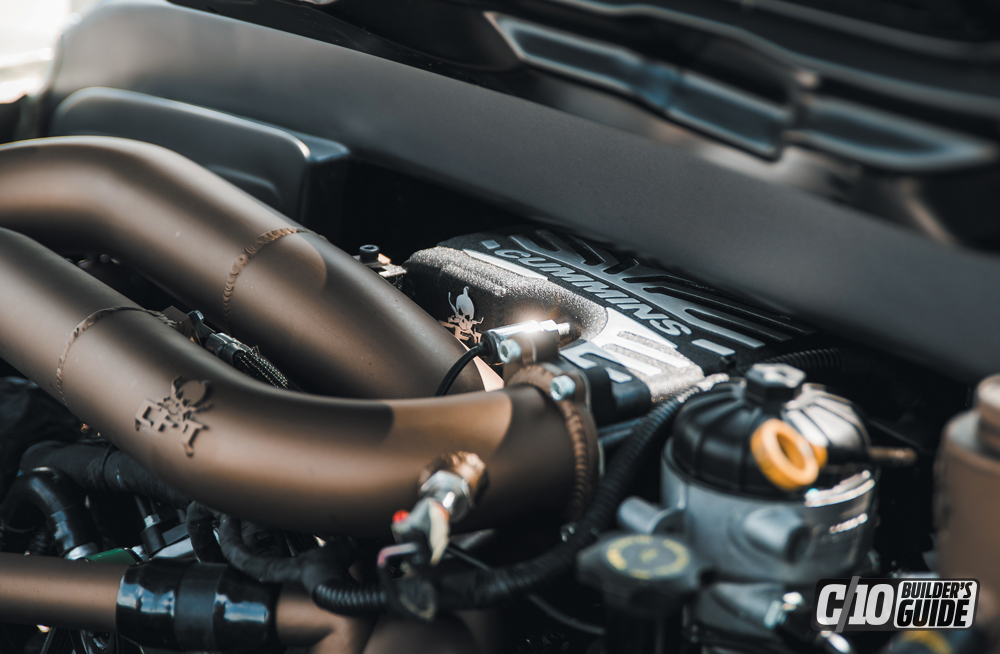

Instead of settling for an LS swap into his ’67 Chevy pickup, Kevin set his sights on something a little larger in scale that would indeed be accompanied by a ton more labor and logistical preparation to get it to work. For this build, nothing less than a Cummins 5.0L turbo diesel engine would do, and Kevin so happened to have access to one, along with a matching Aisin 6-speed automatic transmission—both harvested from the same ’16 Nissan Titan XD. Now, before we get too much further into this tale, the answer is YES. Yes, this idea is insanely awesome, a little bit bonkers, but not impossible, which is really what fueled Kevin’s fire to see this first-of-its-kind swap done and done right.

Instead of settling for an LS swap into his ’67 Chevy pickup, Kevin set his sights on something a little larger in scale that would indeed be accompanied by a ton more labor and logistical preparation to get it to work. For this build, nothing less than a Cummins 5.0L turbo diesel engine would do, and Kevin so happened to have access to one, along with a matching Aisin 6-speed automatic transmission—both harvested from the same ’16 Nissan Titan XD. Now, before we get too much further into this tale, the answer is YES. Yes, this idea is insanely awesome, a little bit bonkers, but not impossible, which is really what fueled Kevin’s fire to see this first-of-its-kind swap done and done right.

To pull off this killer engine swap into a C10, Kevin knew that he had to start from the ground up, which is why he opted to start the build with a Schwartz Performance G-Machine full chassis. This frame is custom-tailored for ’67-’72 C10 pickups, and it would give the truck a 4-inch drop naturally while providing more strength to handle the extra weight of the Cummins, as well as better harnessing the extra power it will soon be making. Of course, custom engine and trans mounts would need to be fabricated to house the diesel power plant, which would end up sitting 26 inches farther back from the factory Chevy engine location. This would the furthest thing from a straightforward drop-in engine swap, that’s for sure, but one that would bring with it “first-ever” status in a C10 platform. The extra work would be well worth the results.

The only thing the unorthodox Cummins swap has in common with an LS swap in any way is the Cold Case radiator and fans that were designed for that specific engine platform. The installation of the radiator, however, was tweaked a bit as it’s slanted back at the bottom to promote enhanced cooling. Kevin picked up this method of installation from old circle track friends of his and put it to good use with the C10’s diesel swap. This makes for added performance benefits and lends to the already out-of-the-ordinary appearance underneath the hood.

The work that went into successfully pulling off the Cummins install was intensive to say the least, but Kevin fell into familiar territory when it came time to work on the truck’s exterior. For the last 25 years, he has worked in the paint and body field specifically, so this portion of the build process would be a little more predictable than the engine swap. The C10 does have an ultra smooth outer appearance, and that is greatly accomplished through the integrated front and rear roll pans, customized grille, Brothers one-piece door glass, smoothed fiberglass cowl, and the drilling and powdercoating of the OE door handles. Kevin selected a nice neutral tan color paint to serve as the base, and recruited the help of Steve Longacre and Jamie Mullican to design and apply the half body wrap.

The bed received a hearty bit of upgrading as well, as Kevin opted to raise the floor 3 inches to better stash the four-link suspension lurking below and then treat it to a custom floor kit from Smokey Road Rod Shop. The aluminum strips in the package can be treated with wood-like graphics or something completely custom, which Kevin selected. The bed floor sports a carbon fiber appearance with the truck’s logo emblazoned dead center. Now, no high-performance vehicle is complete without a rear spoiler, and since this truck is a true race-ready ride, a Nine Lives Racing adjustable spoiler was installed atop the tailgate, looking right at home. The modification that gets the most attention in the bed or at the rear of the truck, however, is the placement of the exhaust system/exit location. The pipe runs the entire length of the inside of the bed and is routed out to push that sweet black smoke through to the outer rear passenger corner. It’s a bit kooky, but that’s exactly what Kevin (and the rest of us) dig about it.

Since Kevin built his C-Tane truck to be functional and drivable on a daily basis if he so desired (not just on the track), he figured that fully decking out the interior was a necessity. To start, he contacted TMI Products to transform the seating situation and dash area, while relying on Jan Van Kooten of Stitch by Stitch Design to get the door panels in line, as well as the one-off center console that had to be made to accommodate the engine setback. A Holley RacePak IQ Logger dash has been installed to keep track of the engine’s vitals, while separate Dakota Digital boost, EGT and fuel gauges add to the essential readouts on the dashboard. An Alpine head unit and Kicker Audio speakers and amp give Kevin something to listen to while ripping around town.

Since Kevin built his C-Tane truck to be functional and drivable on a daily basis if he so desired (not just on the track), he figured that fully decking out the interior was a necessity. To start, he contacted TMI Products to transform the seating situation and dash area, while relying on Jan Van Kooten of Stitch by Stitch Design to get the door panels in line, as well as the one-off center console that had to be made to accommodate the engine setback. A Holley RacePak IQ Logger dash has been installed to keep track of the engine’s vitals, while separate Dakota Digital boost, EGT and fuel gauges add to the essential readouts on the dashboard. An Alpine head unit and Kicker Audio speakers and amp give Kevin something to listen to while ripping around town.

Will we see more diesel engine swaps in C10 trucks in the future? Probably more than there has been in the past, hopefully. Will they be as cool as this truck? Kevin did set the bar pretty high to start, but it will be fun to see what other builders bring to the table. While the price of admission was high, he can boast that his C10 was the first ever to be powered by a Cummins 5.0L. That is one hefty bragging right, but not the only impressive facet of this project. We’re hoping to see more builds inspired by Kevin’s drive to pull off an idea so wildly different, which is what truly keeps this whole scene interesting.

Build Specs

Build SpecsKevin Tetz

Columbia, TN

1967 Chevy C10

Shop: Joshua Chapman / CFT Performance (Maryville, IL)

2016 Nissan Titan XD 5.0L Cummins turbo diesel engine

2016 Nissan Titan XD 2WD Aisin 6-speed auto transmission

Custom engine and transmission mounts

Titan fixed yoke transmission flange

Eaton Truetrac limited slip

TCI shifter

Nissan Titan OE isolators

CFT ported and polished factory intake manifold

Custom 4-inch exhaust system

MagnaFlow muffler, Challenger tips with custom Cerakote finish

Nissan Titan ECM and TCM ignition

CFT custom fabricated boost and inlet tubes, finished in Cerakote

Cold Case LS Swap radiators, fans and transmission cooler

Vintage Air HVAC condenser

Kiwi Customs designed cooling module

Summit Racking 4-inch core air-to-air intercooler

Painless wiring chassis system

CTT Performance 5-stage calibration

Fass Fuel Systems Titanium Series lift pump

Paint by Kevin Tetz, wrap design by Steve Longacre (Preferred Line Media) and Jamie Mullican (the wrap artist)

Axalta Desert Khaki waterborne basecoat and 7900S clearcoat

Paint hand rubbed and polished with Griot’s Garage Systems

Custom Triworks laser cut grille

Integrated front and rear roll pans

Front fiberglass Slosh Tubz

United Pacific yellow tinted LED headlamps with integrated turn signals

Custom fog lamps

3-inch raised bed floors with Smokey Road Rod Shop aluminum bed

Nine Lives Racking rear spoiler

Drilled and powdercoated OE door handles

Brothers one-piece door glass

Smoothed fiberglass cowl

Munssey Speed carbon fiber heat extractors

All American Billet hood hinges

Schwartz Performance G-Machine full chassis

Powdercoated chassis

SLA front, splined sway bars, all spherical joints standard on all Schwartz full chassis kits

Rear triangulated four-link

Ride Tech adjustable coilover shocks at each corner

E-Stopp electric parking brake

Rick’s Tank 18-gallon baffled stainless steel fuel tank

Baer 14-inch rotors, 6-pison calipers, Remaster master cylinder and proportioning valve

Crown Performance custom brake lines

18×12 Rocket Racing Attack Series wheels

335/30/18 BFGoodrich Rival S tires

Shop: Jan Van Kooten (Stitch by Stitch Design), Cookeville, TN

TMI Products seating, black vinyl with red contrast stitching

Holley RacePak IQ3 Logger dash

Summit Racing steering column and wheel

Custom designed and upholstered center console to accommodate engine setback

Vintage Air A/C

Dakota Digital boost, EGT and fuel gauges

Lokar pedal covers

Alpine navigation head unit

Kicker Audio amp and speakers

Share Link