Chris Hamilton

.

February 06, 2026

.

Blood Sweat and Gears

.

Chris Hamilton

Chris Hamilton

.

February 06, 2026

.

Blood Sweat and Gears

.

Chris Hamilton

AS SEEN IN OUR FEBRUARY 2026 ISSUE – Buy Now!

For many Jeep Gladiator owners, the joy of owning a capable, go-anywhere truck is tempered by one persistent reality: rear-end sag under load. Whether hauling a weekend’s worth of camping gear, a bed full of construction materials, or towing a trailer to the dunes, the Gladiator’s rear suspension compresses noticeably, raising headlights, reducing ground clearance, and compromising handling. The fix? Air Lift company‘s LoadLifter 5000 Ultimate kit (PN 57415) is a proven, bolt-on air spring system designed specifically for the JT platform.

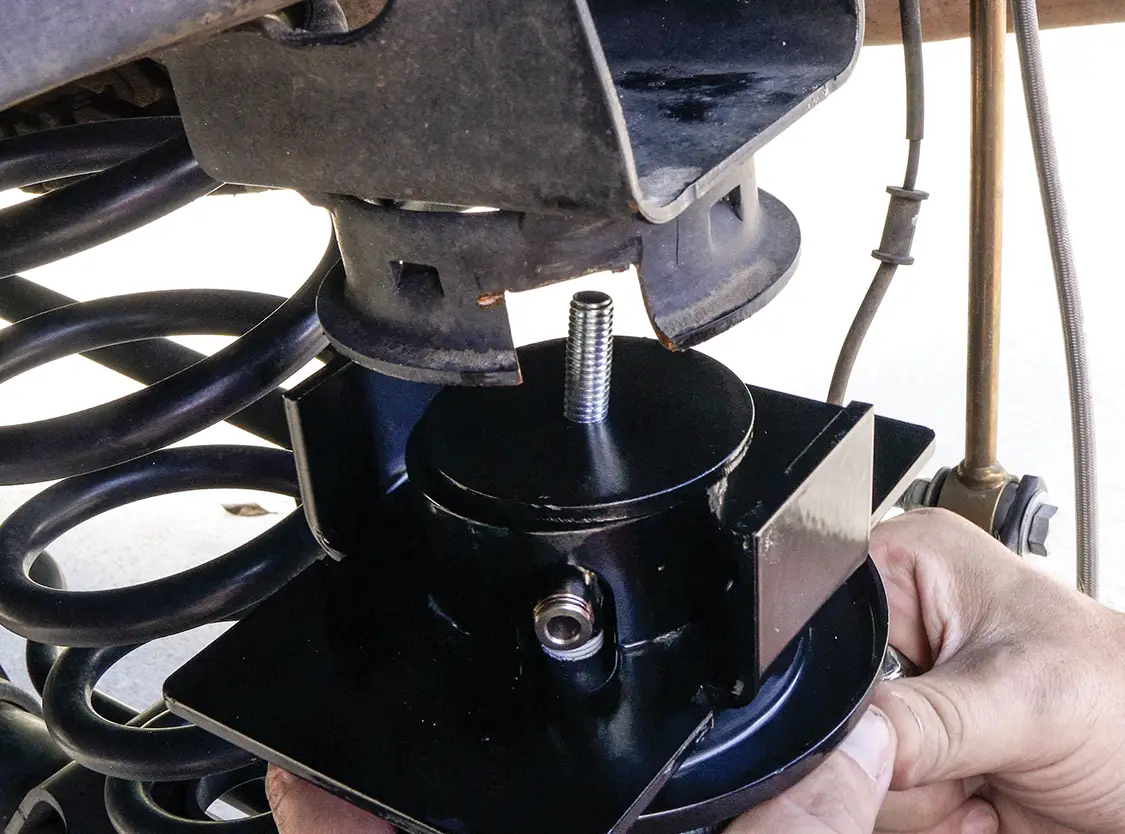

This kit integrates a pair of robust, double-bellow air springs inside the factory coil springs, providing adjustable load support from 5 to 100 psi. Rated for up to 3,400 pounds of leveling capacity, it far exceeds the needs of most owners while maintaining full compatibility with the Gladiator’s stock suspension. The result is a level stance under load, improved steering response, reduced body roll, and more consistent braking performance—benefits that translate directly to safer, more controlled operation whether on pavement or gravel.

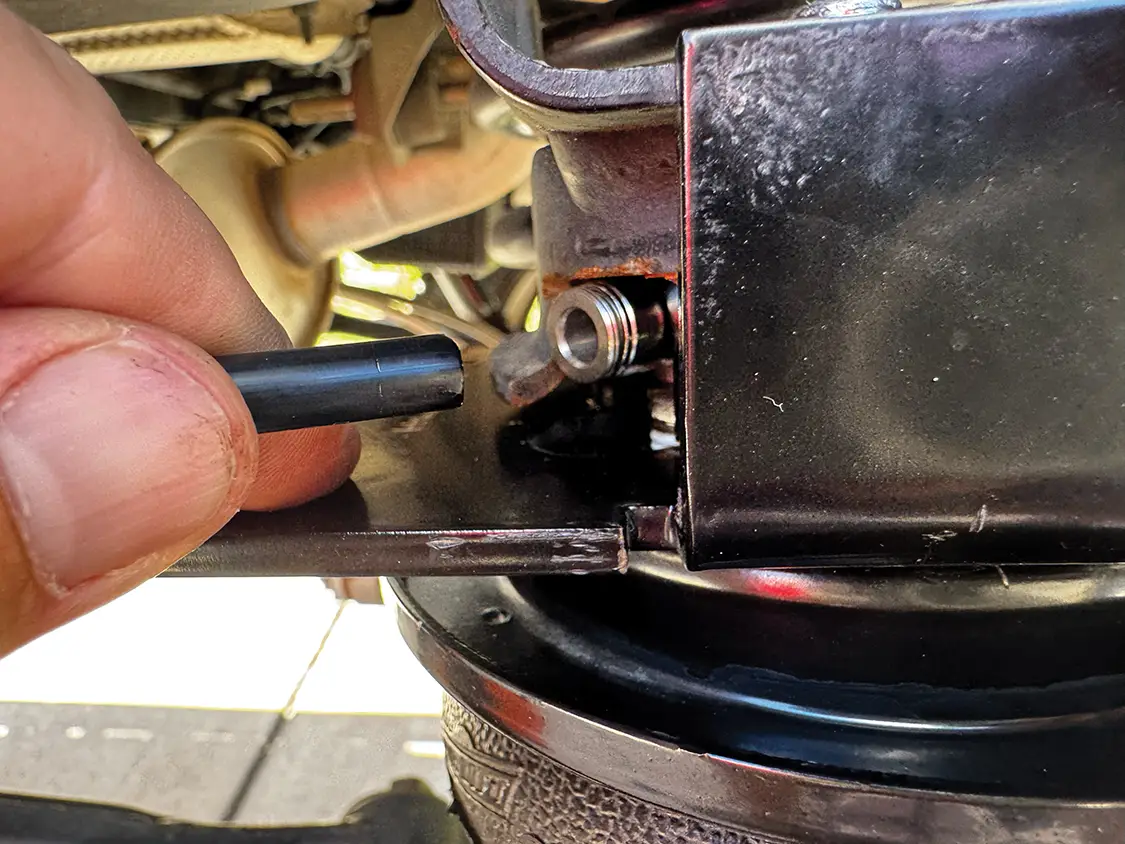

Installation is straightforward and requires no welding or frame modification beyond minor trimming in select areas. Using common hand tools, including a ratchet, sockets, a torque wrench, and a die grinder, the kit bolts into place in an afternoon. Key components include reinforced upper and lower brackets, roll plates for load distribution, and stainless steel braided air lines. Brake line relocation brackets are included to maintain proper routing and clearance. Air can be managed via Schrader valves mounted in the rear bumper or wheel well or upgraded with an onboard compressor for on-the-fly adjustments.

In testing, inflating the system to 55–60 psi restored factory ride height with a truck loaded on our trailer. The Gladiator tracked straight, tire wear remained even, and the ride quality, while firmer under load, remained compliant and controlled. For owners who use their Jeeps as daily drivers and weekend workhorses, the LoadLifter 5000 Ultimate delivers a practical, durable solution that preserves off-road capability while eliminating sag.

The kit represents a cost-effective upgrade for anyone tired of watching their tail drag. It’s a smart investment in safety, performance, and peace of mind—one that lets the Gladiator live up to its full potential, load after load.

Watch Install Here!

Share Link