Bob Ryder

.

January 22, 2026

.

Features

.

TIM SUTTON

Bob Ryder

.

January 22, 2026

.

Features

.

TIM SUTTON

WE’VE NOTICED THAT EARLY MODEL SUVS HAVE MADE A BIG SPLASH IN THE CUSTOM TRUCK SCENE, AND WHY NOT? THOSE MASSIVE, LONG ROOF LAND YACHTS, ALSO KNOWN AS FAMILY HAULERS, COULD TRANSPORT OR TOW ANYTHING. For many years, Rene Hagen from Abbenbroek, Netherlands, a province of South Holland, had been an American hot rod enthusiast. During a trip to the States to enjoy the 2013 SEMA Show, Rene extended his journey and visited Scott’s Hotrods (SHR) located in Oxnard, California. After meeting with owner Justin Padfield and taking the royal tour of the massive SHR facility, Rene noticed a ’65 Suburban sitting in the shop. He asked Justin what the plans were for the Sub, and Justin told him, “It’s going to be the official SHR shop truck.” Nevertheless, Rene asked if the Sub was for sale. “Of course,” Justin said, “Everything is for sale at the right price.”

After returning to his home in Abbenbroek, Rene kept thinking about that ’65 Sub sitting in the shop and how very cool it was. After a few months, he couldn’t stand it any longer, so he gave Justin a call. The two made a deal, not only for Rene to buy the Sub, but also for SHR to build it. Justin said if they were going to build it, the shop would create a one-of-a-kind Suburban that would be timelessly cool.

After separating the massive body from the frame, both parts were sent off to Pacific Coast Powder Coating in Palmdale, California. There they were media blasted to bare metal. Next, the frame rails were boxed, and the rear frame rails were step- notched 8 inches to allow for ample rear axle housing and suspension travel when in full compression with the Super Slam RideTech Firestone airbags deflated. An SHR center tube cross member using 1 ½- inch OD with .125-wall thickness steel was welded between the frame rails for increased strength and rigidity.

Anchoring the Ford 9-inch rearend housing was an SHR 4-bar, 4-link system. A pan hard bar was assembled and bolted to the rearend and frame to eliminate any lateral movement. SHR’s Super Slam RideTech Firestone pneumatic ’bags were then installed to allow maximum negative vertical travel. To woo the horsepower axles on the rearend, a pair of rear Wilwood 14-inch-diameter cross-drilled, vented rotors was squeezed by a pair of Wilwood four-piston calipers and pads. Up front, an SHR Super Slam ’bagged independent front suspension was installed.

The original massive factory front cross member that hangs very low was removed. The SHR bolt-in cross member, upper and lower tubular control arms with built-in adjustability, 2-inch dropped spindles, power rack-and-pinion steering, beefier sway-bar, end-links and Super Slam pneumatic ’bags were installed. Front stopping power is provided by a pair of Wilwood aluminum hubs/five studs to the 14-inch, cross-drilled, vented rotors clamped by a pair of six-piston calipers and brake pads. When the front pneumatic ’bags are purged, it allows the Suburban to lay out on its rockers. Spinning, style and grip were about bolting on a set of custom one-off Hot Rods by Boyd aluminum wheels (front 20×8.5, rear 20×12) wrapped in BF Goodrich G-Force rubber (front 245/35ZR-20 and rear 305/35ZR-20).

The choice of power was a 1974 Chevy 454-ci big- block that was delivered to Adams Machine Shop in Lancaster, California. There the engine was disassembled, cleaned, machined, bored, honed, balanced and assembled with all of the right internal and external performance components. A machined GM 454-ci crankshaft was fitted with reconditioned shot-peened connecting rods and Keith Black pistons. A healthy Comp Performance camshaft was carefully inserted into the cam bearings. GM Performance intake/exhaust valves, springs, push rods, lifters and Crawler roller rocker arms complete the valve train assembly. A pair of custom-polished aluminum valve covers was bolted to the cylinder heads. An Edelbrock aluminum water pump circulates the engine’s coolant through a Be Cool aluminum radiator fit with dual SPAL electric fans. A K&N air filter and Holley 750-cfm carburetor deliver the precise air/fuel mixture into the Edelbrock aluminum intake manifold. After all was said and done, the enhanced big-block displacement measures 468 ci; this produces 600 hp and 550 lbs-ft of torque. A pair of custom-designed, bent and welded SHR ceramic-coated headers exhausts burnt gasses. The headers collect into a 3-inch-diameter Flowmaster exhaust that flows into a pair of Flowmaster mufflers. Bow Tie Overdrives in Hesperia, California was responsible for building a stout GM 1992 765R4 four-speed automatic transmission. It was fitted with a PDQ torque converter with a 2,400-rpm stall.

RON MANGUS AND HIS CREW WERE ALLOWED TO BE VERY CREATIVE ON A LARGE SCALE.”

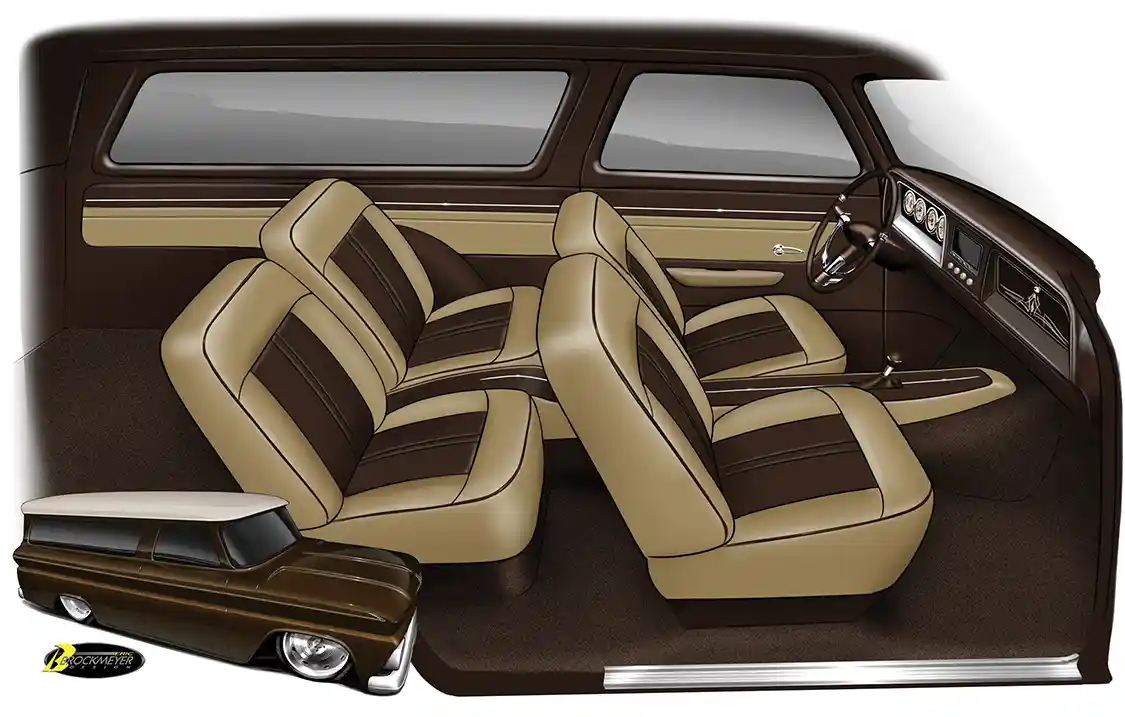

After Rene and Justin discussed body mod ideas, they collaborated with automotive rendering artist Eric Brockmeyer. Eric created a masterpiece, but it’s one thing to draw a design on paper, and quite another to design, fabricate, weld, grind, sand and paint it into reality. It was a complete team effort that transformed the original ’65 Suburban into a metal-sculpted masterpiece with more than 100 body mods. Justin headed up the project, but handed it off to shop foreman Brycen Smith, who along with Kody Smith (no relation), Dennis Smith, Severy Blake, Jerry Contreras, Tyler Padfield, Kyle Fedel, Andy Canchola and Terry Spangler created this flawless jewel.

The most pronounced body modifications were lowering the Sub’s profile. The roof was chopped 2 ½ inches through the rear side windows. The C-pillars were removed, which made room for the massive 6-foot one-piece glass side-widows that were cut by City Auto Glass in Oxnard and mounted flush. The roof drip rails were removed and shaved smooth. To maintain a proportional profile, the body was sectioned 1 ¼ inches through the doors, cowl and fenders. To continue the clear glass appearance, the door quarter-vent windows were removed and replaced with one-piece door glass.

After all of the body mods and bodywork were finished, the Sub was delivered to Palmer’s Custom Paint in Moorpark, California. There Alan applied sanding primer, and then block sanded the sheet metal surfaces to a flawless, smooth finish. The body surface was cleaned and Alan sprayed the AXALTA Macadamia Metallic Brown custom blend. The roof received AXALTA Chrysler Stone White. The basecoat was buried with multiple coats of AXALTA clear. After ample curing time, the massive surfaces were cut, buffed and polished to a glistening shine. The windshield was also cut down to fit the roof’s chop. The door handles were removed then replaced with flush- mounted versions from Kindigit Designs. The factory rear bumper was sectioned and molded into the body to form a clean rear roll pan. A pair of factory-style rear LED taillights was added. Up front, the factory front bumper mounting carriage bolt holes were plugged/welded, ground smooth and narrowed. Then the factory grille and front bumper were sent out to Sherm’s Plating to be dipped, stripped, coppered, nickeled, polished and chromed to perfection. The headlight bezels were filled with a pair of halogen headlights.

The massive cabin was an upholsterer’s paradise. Ron Mangus and his crew at Ron Mangus Hot Rod Interiors in Rialto, California were allowed to be very creative on a large scale. The entire interior was clad with Dynamat sound/heat deadening material. The deadened floor was then covered with Mangus brown/tan square weave carpet. All four Glide bucket seat frames received plenty of foam with additional built up foam leg and lateral bolsters. The seats were covered with Terracotta Tan leather with Alcantara brown leather inserts. A custom center console was also covered with seat-matching tan leather sides and Macadamia Brown suede leather center. The door panels were covered in matching two-tone tan and brown leather. Creating the endless one-piece tan suede leather headliner was a feat in itself. To observe the engine’s vital signs, a set of Classic Instruments round white face gauges was installed into the instrument panel.

This entire build was completed in just 90 days! This incredible, timeless ’65 Suburban is awesome inside and out. ST

OWNER

Rene Hagen

1965 Chevy Suburban

Abbenbroek, Netherlands

BUILDER

Scott’s Hot Rods Oxnard, California

ENGINE

TRANSMISSION

FRAME

SUSPENSION

BRAKES

WHEELS

TIRES

BODY

PAINT

INTERIOR

AUDIO

Share Link