John Mata Jr.

.

January 28, 2025

.

c10

John Mata Jr.

.

January 28, 2025

.

c10

There are many factors that fuel the creation of a true custom vehicle. These factors are often based on personal taste and standards, as well as direct inspiration that led one to decide what is and what isn’t cool in their own book.

“…to me, it doesn’t get more classic than ’67-’72 C10 pickups.”

For guys like Wesley Nelson of Grand Rapids, Wisconsin, figuring out what he liked was easy—kick-ass and unique low-riding pickup trucks. While that does sound like a wide spectrum of things to like, Wesley specifically gives his attention to pickups that had characteristics unlike most others in the crowd.

Wesley’s first full build was a ’99 Ford Ranger that was stock floor body dropped on 22s during the mid-2000s.

“It was one of the first running and driving stock floored Rangers on that size wheel in the country back then,” he states. “I took it to a couple bigger shows like Indy Truck Bash and Camp ‘N Drag (the early years) in primer, but I got burned out with the scene at the time. So I sold the Ranger to a friend and told him I would help do whatever he had in mind for it.”

What Wesley’s friend wanted to do with his ex-Ranger altered the image of the truck he would choose to build next for himself.

“My buddy and I body swapped it to a ’52 International Harvester R110,” Wesley adds. “Seeing the lines of the older metal made me want more of a classic truck for my next full build, and to me, it doesn’t get more classic than ’67-’72 C10 pickups.”

The search for a second-generation Chevy C10 had commenced, and Wesley soon found out that the price for these trucks doesn’t come cheap. After looking around for something that came at somewhat of a deal, he eventually found a ’70 longbed that didn’t even have a bed on it. The truck he found was equipped with a wooden flatbed, and as he would soon learn, there were some problematic areas peppered throughout the truck but nothing that would ultimately hold him back from moving forward with the project.

While Wesley wasn’t 100% sure whether he wanted to set his 1970 Chevy C10 up for big, wide billets or to assemble a full-on race setup, he landed somewhere in the middle with a custom frame that he built himself that utilized the stock front crossmember with 2×4 tube for the rest of the frame rails. Since down was the only direction Wesley was interested in taking his truck, he proceeded to install Slam Specialties SS7 ‘bags and KYB rear shocks, along with a ThorBros heavy-duty universal 4-link for the rear. Hotchkis front and rear HD sway bars were also included in the suspension setup to promote better handling and improved ride quality.

“…he landed somewhere in the middle with a custom frame that he built himself that utilized the stock front crossmember with 2×4 tube for the rest of the frame rails.”

The wheel style and size that Wesley chose to run with also fell between the two directions he was undecided in going. While there’s always room for bigger and wider, the 22×9 VCT Torino units fit the bill for overall good styling and fitment. Front CPP 13-inch slotted and drilled rotors were installed up front, while 2011 Silverado calipers and discs were used at the rear for much quicker and responsive braking, which gives a hint as to Wesley’s appreciation for function just as much as form.

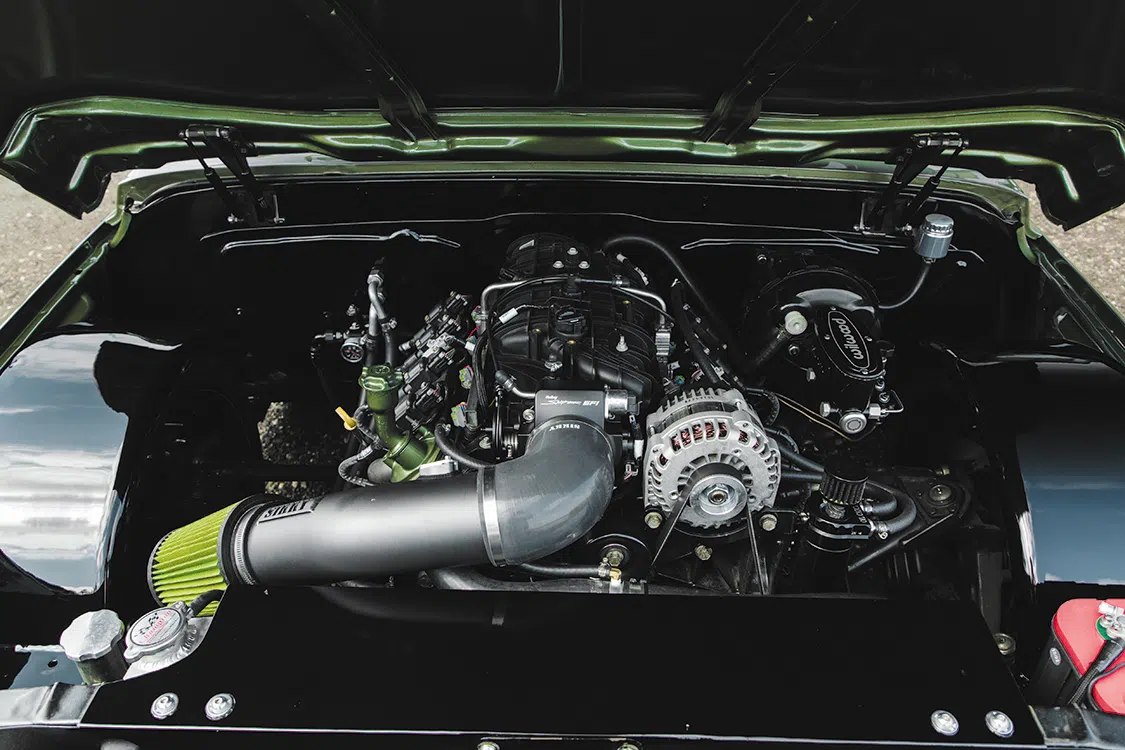

Since Wesley put so much effort in bringing his 1970 Chevy C10 to a quicker stop, you’d figure that he was planning to make the truck go fast, right? That logic would be correct. The 2013 LS engine under the hood is a rewarding sight for those who were inquisitive enough to connect the dots.

“I then reached out to local race shop Krings Motorsports to build another 6.2L LS with all new internals…”

“The truck originally came with a 305 and a 3-on-the-tree, but that just wasn’t going to cut it”, Wesley says proudly. “The first swap was to a 383 Stroker controlled by a Holley Sniper unit. That was eventually yanked for a 2009 LS from a Yukon I bought from eBay. I did some work to it and drove it approximately 300 miles before I sent the piston through the side of the block. Lesson learned—leave the engine work to the professionals. I then reached out to local race shop Krings Motorsports to build another 6.2L LS with all new internals, while reusing the heads and cam from the other LS.”

Wesley then moved on to working on his Chevy C10’s exterior by first shaving the gas cap, outer door locks and cowl vents. While that portion went off without a hitch, a new floor in the cab had to be fabricated due to the original one basically crumbling due to rust corrosion.

With a fresh floor in place, Wesley conducted a shortbed conversion since he had quick access to the frame once the flatbed was removed and still had to track down a new bed anyway. While he was working on the box, the floor was raised and outfitted with oak wood that his grandpa had cut into planks before he passed away.

“I planed the planks down into usable boards, and then routed them and bought computer frame T-slot rails from McMaster to serve as rails to hold it all in place,” Wesley says.

“While he was working on the box, the floor was raised and outfitted with oak wood that his grandpa had cut into planks before he passed away.”

Finishing off the bed are a custom set of rear tubs as well as a tailgate filler panel that was built by Jayke Christenson at Atomic Armadillo Metal Fab in New London, WI.

“The panel reads ‘Common Sense,’ which has become the name of the truck. I just think there is a massive lack of it nowadays, and it gets people talking about while I’m out at shows,” Wesley says.

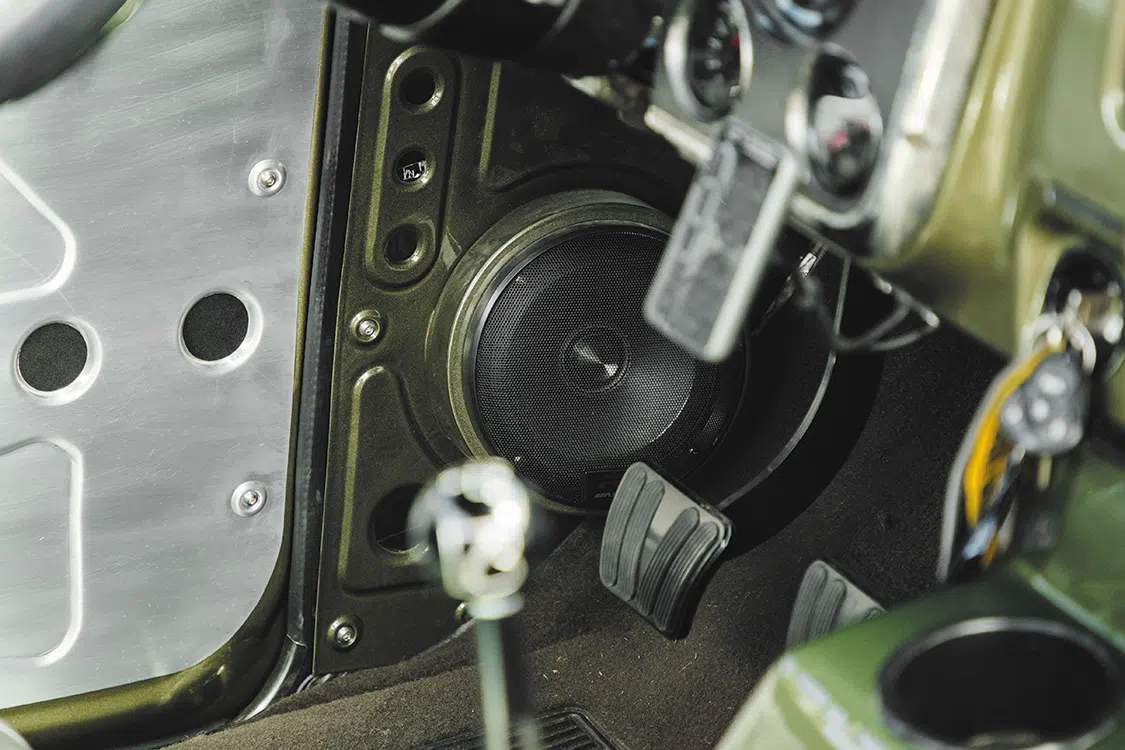

Next up was some much-needed paintwork, which Wesley and his daughter Kristina tackled together. Eastwood’s Shaggin’ Green Metallic paint proved to be a great color selection and was good enough to be utilized inside the cab as well. A one-off center console and bead-rolled, dimple-die door panels designed by Wesley and fabricated in collaboration with Bill Dieterich of Kustom Design Innovations make a huge statement inside of the cab. There’s a slick, utilitarian vibe going on within the confines of the C10, and it just has to be said that it looks cool as hell.

While there are many paths available for Wesley to still explore with his 1970 Chevy C10, it seems that he is already indulging in his many interests in a multitude of various styles and functions thus far. He is currently six years into the build, and even he finds it hard to contain his excitement with its current state.

“A one-off center console and bead-rolled, dimple-die door panels designed by Wesley and fabricated in collaboration with Bill Dieterich of Kustom Design Innovations make a huge statement inside of the cab.”

“I started out with a large pile of rust and title,” Wesley admits humbly. “I would urge others to start with a better base to save yourself a lot of headache. It’s going to take a lot longer than you’d think to build up a truck to this level, and having good likeminded friends like Joe Gellerman, Jeff Cormack, Bill Dieterich, and Jayke Christenson, and family like my daughter Kristina and wife Nicole sure won’t hurt.”

Share Link